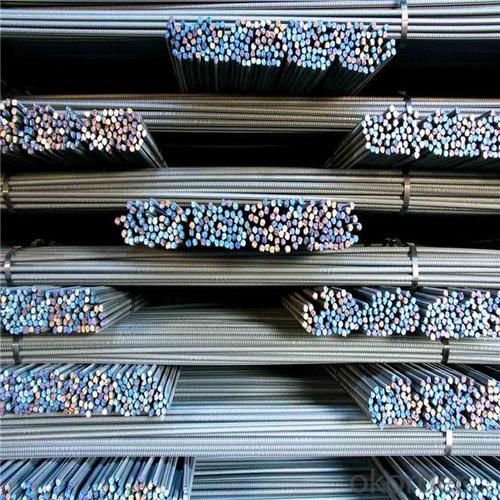

Steel rebar with short delivery time and quality certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Rebar is made of unfinished steel, making it susceptible to rusting. As rust takes up greater volume than the iron

or steel from which it was formed, it causes severe internal pressure on the surrounding concrete, leading to cracking,

spalling, and ultimately, structural failure. This is a particular problem where the concrete is exposed to salt water, as

in bridges built in areas where salt is applied to roadways in winter, or in marine applications. Epoxy-coated rebar or

stainless steel rebar may be employed in these situations at greater initial expense, but significantly lower expense

over the service life of the project. Fiber-reinforced polymer rebar is now also being used in high-corrosion environments

Most grades of steel used in rebar cannot accept welding; such as, to adjacent steel plates or as means to bind single

pieces of rebar together. However, special grades of rebar steel and welding rods make welding by expert welders possible.

To prevent workers from accidentally impaling themselves, the protruding ends of steel rebar are often bent over or covered

with special plastic "mushroom" caps.

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What are the different types of steel rebars used in marine constructions?

- The different types of steel rebars commonly used in marine constructions include stainless steel rebars, epoxy-coated rebars, and galvanized rebars. These types of rebars are chosen for their corrosion resistance properties, which are essential in withstanding the harsh marine environment. Stainless steel rebars are highly resistant to corrosion and are often used in marine structures due to their durability. Epoxy-coated rebars have a protective coating that prevents corrosion, making them suitable for marine applications. Galvanized rebars are coated with a layer of zinc, providing excellent corrosion protection and are commonly used in marine construction projects.

- Q: What is the effect of aging on the properties of steel rebars?

- The effect of aging on the properties of steel rebars is generally negative. Over time, steel rebars may experience gradual deterioration due to factors such as corrosion, fatigue, and stress. This can lead to a reduction in their structural integrity and load-bearing capacity. Aging can also cause an increase in brittleness, making rebars more prone to fractures and failures. Therefore, regular inspections, maintenance, and potentially replacement of aged rebars are crucial to ensure the safety and longevity of structures.

- Q: Can steel rebars be used in residential foundation construction?

- Yes, steel rebars can be used in residential foundation construction. Steel rebars provide reinforcement and strength to concrete, making them an essential component in the construction of residential foundations.

- Q: Can steel rebars be used in structures with high resistance to vibration?

- Yes, steel rebars can be used in structures with high resistance to vibration. Steel rebars have excellent strength and durability properties, making them suitable for reinforcing structures that are subjected to vibrations, such as bridges, high-rise buildings, and industrial facilities. The use of steel rebars helps enhance the structural integrity and stability of these structures, ensuring their ability to withstand and dissipate vibrations effectively.

- Q: What is the importance of proper anchoring of steel rebars in concrete?

- The proper anchoring of steel rebars in concrete is crucial for ensuring the structural integrity and stability of the concrete structure. When rebars are not properly anchored, they may become loose or detached from the concrete, leading to potential structural failure, especially under heavy loads or seismic activity. Proper anchoring helps to distribute stress and load evenly throughout the concrete, preventing cracks, displacement, and collapse. It also enhances the bond between the steel and concrete, improving the overall strength and durability of the structure.

- Q: What are the different methods for cutting steel rebars on-site?

- There are several methods available for cutting steel rebars on-site, depending on the specific requirements and limitations of the project. Some of the common methods include: 1. Manual Cutting: This method involves using handheld manual tools such as rebar cutters or bolt cutters to cut through the steel rebars. It is suitable for smaller projects or areas where power tools may not be accessible. 2. Abrasive Cutting: Abrasive cutting, also known as grinding or cut-off saws, utilizes a high-speed rotating disc with abrasive particles to grind through the steel rebars. This method is effective for cutting rebars of various sizes and is commonly used in construction sites. 3. Torch Cutting: Using oxy-fuel or plasma torches, this method involves heating the steel rebars to a high temperature and then cutting through them using the intense heat. Torch cutting is suitable for thicker and larger rebars but requires caution and safety measures due to the open flame involved. 4. Shear Cutting: Shear cutting involves using hydraulic or mechanical shears to cut through the steel rebars. This method is efficient for cutting rebars quickly and accurately, especially for larger projects. 5. Hydraulic Cutting: Hydraulic cutters use hydraulic pumps to generate high pressure, which is then used to power the cutting blade. This method is commonly used for heavy-duty cutting tasks and can cut through thick rebars with ease. 6. Electric Cutting: Electric cutters, such as electric rebar cutters or portable band saws, are powered by electricity and provide a clean and precise cut. They are commonly used in construction sites where power is readily available. It is essential to consider the specific requirements of the project, including the size and thickness of the rebars, available power sources, and safety considerations, when selecting the appropriate method for cutting steel rebars on-site.

- Q: What are the main characteristics of steel rebars?

- Steel rebars, also referred to as reinforcing bars, are an integral part of construction and engineering projects due to their unique characteristics. To begin with, steel rebars possess exceptional strength and durability. Made primarily from carbon steel, they exhibit high tensile strength, enabling them to withstand heavy loads and stresses without deforming or failing. This strength is crucial in reinforcing concrete structures, enhancing their structural integrity and ability to resist bending, cracking, and shear forces. Another significant characteristic of steel rebars is their resistance to corrosion. Since steel is susceptible to rusting when exposed to moisture and air, rebars are often coated with epoxy or other protective materials to prevent corrosion. This ensures the longevity and durability of reinforced concrete structures, making them suitable for various environments, including marine or high humidity areas. Moreover, steel rebars possess excellent thermal conductivity, allowing them to efficiently disperse heat. This is particularly important in structures that face extreme temperatures or fire hazards. Additionally, their ribbed or deformed surface enhances their bonding properties with concrete, preventing slippage and providing improved structural stability. Furthermore, steel rebars are versatile and can be easily shaped and bent to suit the specific design or specifications of a construction project. They are available in various sizes, lengths, and grades, giving engineers and architects the flexibility to choose the appropriate type of rebar based on the specific load-bearing requirements of the structure. In conclusion, the key characteristics of steel rebars include their strength, durability, corrosion resistance, thermal conductivity, bonding properties, and versatility. These qualities make steel rebars an indispensable component in construction, ensuring the safety, stability, and longevity of reinforced concrete structures.

- Q: Are steel rebars suitable for use in structures with high resistance to impact?

- Steel rebars are generally suitable for use in structures with high resistance to impact. Rebars, also known as reinforcement bars, are made from steel and are commonly used in concrete structures to enhance their strength and durability. Steel is known for its high tensile strength and ability to absorb and distribute impact forces, making it an ideal material for reinforcement. In structures that are prone to impact, such as bridges, highways, or buildings located in earthquake-prone areas, steel rebars play a critical role in providing additional strength and resistance. The use of rebars ensures that the structure can withstand sudden impact loads and prevent catastrophic failures. Moreover, steel rebars are available in various grades and sizes, allowing engineers to select the appropriate type of rebar based on the specific requirements of the structure. Higher grade rebars, such as Grade 60 or Grade 75, offer increased strength and ductility, making them even more suitable for structures with high resistance to impact. It is important to note that while steel rebars enhance the overall strength and impact resistance of a structure, other factors such as design, construction techniques, and maintenance also play vital roles in ensuring the structure's ability to withstand impact forces. Therefore, a comprehensive approach that considers all these factors is essential in designing and constructing structures with high resistance to impact.

- Q: How are steel rebars different from steel mesh?

- Steel rebars and steel mesh are both reinforcing materials used in construction, but they differ in terms of their shape, size, and application. Steel rebars are long, cylindrical bars typically made of carbon steel and are used to provide tensile strength and stability to concrete structures, such as beams, columns, and foundations. On the other hand, steel mesh consists of a grid-like pattern of interconnected steel wires and is used primarily to reinforce concrete slabs, walls, and other flat surfaces. While rebars are primarily used to resist tension, steel mesh distributes loads evenly and helps prevent cracking and shrinkage in concrete.

- Q: Can steel rebars be used in bridge construction?

- Yes, steel rebars can be used in bridge construction. Steel rebars are commonly used to reinforce concrete structures, including bridges, due to their high strength and durability. They provide additional support and improve the overall structural integrity of the bridge.

Send your message to us

Steel rebar with short delivery time and quality certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords