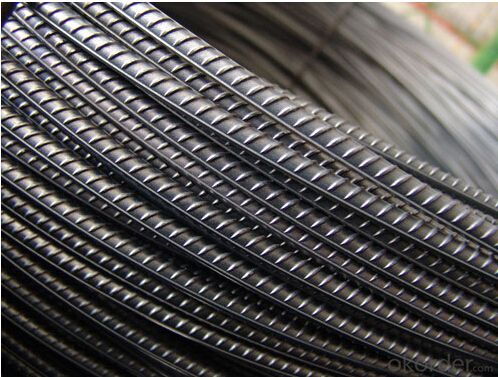

BEST QUALITY REBAR --STEEL PRODUCT FROM CHINA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | ASTM,BS,GB,KS,GB, BS ,KS, ASTM | Grade: | HRB400 | Diameter: | 6mm-40mm |

| Length: | 6-12meters,6m-12m | Place of Origin: | Hebei China (Mainland) | Brand Name: | Haixing |

| Model Number: | FHX | Application: | construction | color: | black |

| Package: | Within bundles | Thechique: | hot rolled |

Packaging & Delivery

| Packaging Detail: | MIill's export standard packing in bundles with wire rod as customer's requirement |

| Delivery Detail: | within 30 days |

Specifications

Certificates: CE & ISO9001:2000

Material: hrhrb400 ,hrb500, BS4449, ASTM A615, SD400

length:6-12

Size: 6mm-40mm

Product Description Material: HRB400,HRB500, BS4449,ASTM A615 GR40/60, SD400 usuage: building and construction |

- Q: What are the factors to consider when choosing steel rebars for a project?

- When choosing steel rebars for a project, there are several important factors to consider. 1. Grade of Steel: The grade of steel rebars determines its strength and durability. It is crucial to select a grade that is appropriate for the specific project requirements and structural design. Higher grades of steel rebars provide better resistance to corrosion and have higher tensile strength. 2. Size and Shape: The size and shape of the rebars should be chosen based on the structural design and load requirements. Different projects may require different diameters and lengths of rebars. It is important to consider the specific dimensions and spacing requirements to ensure optimal reinforcement. 3. Corrosion Resistance: Depending on the project's location and exposure to environmental conditions, it is essential to select rebars with appropriate corrosion resistance. This can be achieved by using rebars with protective coatings, such as epoxy or galvanized coatings, or by choosing stainless steel rebars. 4. Weldability: If welding is required for the project, it is important to consider the rebars' weldability. Some rebars may require special procedures or preheating before welding, while others may not be suitable for welding at all. 5. Cost: The cost of steel rebars can vary based on grade, size, and other factors. It is important to balance the project's budget with the required quality and strength of the rebars. Additionally, considering the rebars' lifecycle cost, including maintenance and potential repairs, can help make a more economical choice. 6. Availability: The availability of the required rebars in the local market should be considered. It is important to ensure that the desired grade, size, and quantity of rebars are readily available to avoid delays in the project. 7. Compliance with Standards: Steel rebars should meet the relevant national or international standards, such as ASTM or BS, to ensure their quality and performance. Compliance with these standards ensures that the rebars have been manufactured and tested to meet specific requirements. 8. Expert Advice: Consulting with structural engineers or experts in steel reinforcement can provide valuable insights and recommendations. They can assess the project's needs and provide guidance on the most suitable rebars for the specific application. Considering these factors will help ensure the selection of appropriate steel rebars that meet the project's requirements in terms of strength, durability, corrosion resistance, and cost-effectiveness.

- Q: Can steel rebars be used in the construction of underground parking structures?

- Yes, steel rebars can be used in the construction of underground parking structures. Steel rebars are commonly used in reinforced concrete structures, including underground parking structures, to provide tensile strength and reinforcement. The rebars are typically placed strategically within the concrete to enhance its load-bearing capacity, durability, and resistance to cracking or deformation. Due to their high strength and ability to withstand heavy loads, steel rebars are well-suited for underground parking structures that require robust structural support. Additionally, the corrosion resistance of steel rebars can be further enhanced by applying protective coatings or using stainless steel rebars, which is particularly important in underground environments where moisture and exposure to chemicals may be present. Overall, the use of steel rebars is a standard practice in the construction of underground parking structures to ensure the structural integrity and longevity of the facility.

- Q: What are the common applications of steel rebars?

- Steel rebars are commonly used in construction projects to reinforce concrete structures such as buildings, bridges, and highways. They provide strength and stability to the concrete, enabling it to withstand tension and prevent cracks or collapse. Additionally, steel rebars are used in various other applications including retaining walls, dams, tunnels, and even in the automotive industry for manufacturing durable frames and chassis.

- Q: What are the guidelines for storing steel rebars on a construction site?

- When it comes to storing steel rebars on a construction site, there are several guidelines that should be followed to ensure safety and maintain the quality of the rebars. Here are some key guidelines: 1. Location: Select a designated area on the construction site that is flat, clean, and well-drained for storing the rebars. Avoid areas prone to flooding or excessive moisture. 2. Elevation: Keep the rebars off the ground by using wooden or concrete blocks to prevent direct contact with soil or water. This helps prevent rusting and corrosion. 3. Stacking: Stack the rebars in a stable manner, ensuring that they are aligned vertically and horizontally to maintain their shape and prevent any bending or warping. Use spacers or crates between layers to maintain proper spacing and prevent entanglement. 4. Protection from elements: Cover the rebars with a waterproof tarp or plastic sheet to protect them from rain, snow, or excessive sunlight. This helps prevent rusting and degradation of the rebars. 5. Separation: Store different sizes and types of rebars separately to avoid mixing or confusion during construction. Clearly label and mark each stack to identify the type, size, and grade of the rebars. 6. Accessibility: Ensure easy access to the rebars for construction workers by organizing them in a logical manner. Place smaller rebars on top for easy retrieval and avoid storing heavy rebars on top of lighter ones to prevent damage. 7. Safety precautions: Maintain a safe distance between the rebars and any heavy machinery or equipment to minimize the risk of accidents. Secure the rebars properly to prevent them from falling or causing injury. 8. Regular inspection: Regularly inspect the rebars for any signs of damage, rust, or corrosion. Replace or repair any damaged or compromised rebars to avoid compromising the structural integrity of the construction project. By adhering to these guidelines, construction sites can ensure the proper storage of steel rebars, promoting safety, efficiency, and the longevity of the rebars.

- Q: How do steel rebars contribute to the seismic performance of concrete buildings?

- Steel rebars contribute to the seismic performance of concrete buildings by providing reinforcement and strength to the structure. The rebars help to distribute and dissipate the energy generated during an earthquake, increasing the building's ability to withstand the seismic forces. They enhance the concrete's tensile strength, preventing cracking and enhancing its overall durability. The combination of concrete and steel rebars creates a composite material that can absorb and withstand the lateral forces caused by ground shaking, reducing the risk of structural failure during seismic events.

- Q: How do steel rebars contribute to sustainable construction practices?

- Steel rebars contribute to sustainable construction practices in several ways. Firstly, they are made from recycled materials, reducing the need for new resources and minimizing the environmental impact of steel production. Additionally, steel rebars have a long lifespan and high durability, leading to less frequent replacement and maintenance, which in turn reduces waste and energy consumption. Moreover, steel rebars provide structural strength to reinforced concrete, allowing for the construction of taller and more efficient buildings, which can optimize land use and minimize the urban sprawl. Overall, steel rebars play a vital role in sustainable construction by promoting resource conservation, reducing waste, and enhancing the longevity and efficiency of structures.

- Q: What are the specifications for steel rebars used in high-rise buildings?

- The specifications for steel rebars used in high-rise buildings typically include requirements for the diameter, tensile strength, yield strength, and elongation percentage of the rebars. The diameter can range from 6mm to 50mm, depending on the structural requirements. The tensile strength is usually specified as a minimum value, such as 500MPa or 600MPa. The yield strength is typically higher than the tensile strength and can be around 420MPa to 600MPa. The elongation percentage specifies how much the rebar can stretch before it breaks, and it is often required to be at least 14% or higher. Additionally, the rebars used in high-rise buildings must meet specific standards and codes, such as ASTM A615 or BS4449, to ensure their quality and performance in the construction process.

- Q: What are the different types of steel rebars used in beam reinforcement?

- There are several types of steel rebars commonly used in beam reinforcement. These include: 1. Mild Steel Rebars (MSR): These rebars are made from low carbon steel and are widely used due to their affordability and availability. They have a yield strength of 250 MPa and are suitable for general construction purposes. 2. High Yield Strength Rebars (HYSD): These rebars have a higher yield strength compared to mild steel rebars, typically ranging from 415 MPa to 600 MPa. HYSD rebars are commonly used in heavy-duty and high-stress applications, such as bridges and high-rise buildings. 3. Carbon Steel Rebars: These rebars are made from carbon steel, which contains a higher carbon content than mild steel rebars. Carbon steel rebars offer improved strength and ductility, making them suitable for seismic zones and areas prone to corrosion. 4. Stainless Steel Rebars: These rebars are made from stainless steel, which contains a high percentage of chromium and other alloying elements. Stainless steel rebars offer excellent corrosion resistance, making them ideal for structures exposed to harsh environments, such as marine applications or chemical plants. 5. Epoxy-Coated Rebars: These rebars are coated with an epoxy layer to provide additional protection against corrosion. Epoxy-coated rebars are commonly used in structures exposed to moisture or chloride-rich environments, such as coastal regions or areas with deicing salts. It is important to consider the specific requirements and conditions of the project when selecting the type of steel rebar for beam reinforcement. Consulting with structural engineers or industry professionals is recommended to ensure appropriate material selection for optimal performance and longevity of the reinforced beam.

- Q: What are the different types of couplers used for connecting steel rebars?

- There are several types of couplers used for connecting steel rebars, including mechanical couplers, lap splices, and grouted splices. Mechanical couplers are typically threaded or tapered and provide a mechanical connection between the rebars. Lap splices involve overlapping the rebars and securing them with tie wires or welding. Grouted splices involve placing the rebars in a sleeve or coupling filled with grout to create a bonded connection.

- Q: What is the effect of steel rebars on the electrical conductivity of concrete?

- Steel rebars have a significant effect on the electrical conductivity of concrete. As steel is a highly conductive material, the presence of steel rebars in concrete increases its overall electrical conductivity. This is due to the fact that steel rebars create a network of conductive paths throughout the concrete matrix, allowing for the easy flow of electrical current. The electrical conductivity of concrete is an important factor to consider, especially in applications where electrical grounding or conductivity is necessary. Steel rebars aid in providing a low-resistance pathway for electrical current, improving the overall electrical conductivity of the concrete structure. However, it is essential to note that the presence of steel rebars can also introduce potential challenges in certain scenarios. For instance, in electrical installations where insulation is required or in areas where electrical isolation is necessary, the conductivity provided by steel rebars may not be desired. In such cases, additional measures like insulation or isolation techniques need to be employed to prevent unwanted electrical currents from flowing through the concrete. Overall, the effect of steel rebars on the electrical conductivity of concrete is dependent on the specific requirements and applications of the concrete structure. Understanding the intended use and implementing appropriate measures accordingly will ensure that the electrical conductivity of the concrete meets the desired specifications.

Send your message to us

BEST QUALITY REBAR --STEEL PRODUCT FROM CHINA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords