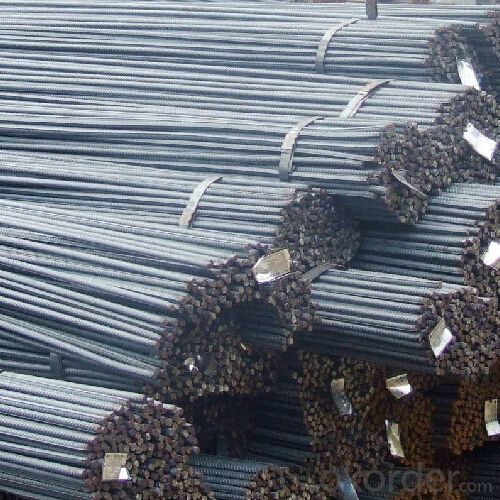

This World's Best Rebar From Chines Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 22222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Wire Rod Steel for Construction Description

the wire rod steel for construction that we offer have been used in civil construction work for years.

2.Main Features of the Wire Rod Steel for Construction

fasteners, bolts, rivets, screws,

general purpose wires,

electrode wires, industrial wires, agriculture wires,

bush wires, chain rivet wires,

detonator wire,

Umbrella ribs, upholstery wires, cycle spokes, needle wires, heald wires, staple pin Wire, safety pin wires

ACSR wires, earth wires,

tyre and hose reinforcement wires,

prestressed concrete wire, springs and rope wires,

card clothing wires,

vineyard wires,

ball bearing quality

Automobile parts like screw, fasteners, bush, spline, socket, connecting rod, shaft, gear, rivets, engine shaft, connecting rod, spindles, gears, etc.

3.Wire Rod Steel for Construction Images

4.Wire Rod Steel for Construction Specification

Grade | Chemical Composition(%) | |||||

C | Mn | Si | S | P | B | |

SAE1006B | 0.03~O.07 | ≤0.32 | ≤0.30 | ≤0.045 | ≤0.040 | >0.0008 |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

250-280 | 350-380 | ≥32 | ||||

Grade | Chemical Composition(%) | |||||

C | Mn | Si | S | P | B | |

SAE1008B | 0.10max | 0.3~O.50 | 0.15max | 0.050max | 0.040 max | 0.0008 min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

≥195 | 315-430 | ≥30 | ||||

5.FAQ of Wire Rod Steel for Construction

1.What is your minimum order quantity ?

Our MOQ is 500mt .

2.Please tell me the daily output and wire rod mill’s brand ?

Our daily output is 4000mt/day and our rolling mill from Germany’s SMS MEER

3.Which countries are your main sales?

Thanks to the professional international trade team, solid distribution channel and long – term cooperation customers, our market share in overseas realizes a tremendous growth, now we already became a main player in Middle East and South East Asia. Meanwhile, we are also the biggest supplier of Pre-painted galvanized steel coil in Philippines, Saudi Arabia, United Arab Emirates, Iran, Sudan etc.

- Q: How are steel strips coated or treated for corrosion resistance?

- Steel strips are commonly coated or treated for corrosion resistance through processes such as galvanization, where a layer of zinc is applied to the surface of the steel to provide a protective barrier against corrosion. Additionally, steel strips can be treated with various types of coatings, such as organic or inorganic coatings, that create a barrier between the steel and corrosive elements in the environment. These coatings are often applied through methods like hot-dip coating, electroplating, or painting, depending on the specific requirements and desired level of corrosion resistance.

- Q: What is the creep resistance of a steel strip?

- The creep resistance of a steel strip refers to its ability to resist deformation over time under constant stress and elevated temperatures.

- Q: Can steel strips be used in packaging or strapping applications?

- Yes, steel strips can be used in packaging or strapping applications.

- Q: How are steel strips processed for formability?

- Steel strips are processed for formability through various techniques such as annealing, cold rolling, and tempering. Annealing involves heating the steel strip to a specific temperature and then slowly cooling it, which helps to soften the steel and improve its formability. Cold rolling is another method where the steel strip is passed through a series of rollers at room temperature, reducing its thickness and enhancing its ductility. Tempering is also utilized to further improve the formability by reheating the steel strip to a specific temperature and then rapidly cooling it. All these processes help to enhance the formability of steel strips, making them more suitable for shaping and forming into desired products.

- Q: How are steel strips processed for load-bearing capacity?

- Steel strips are processed for load-bearing capacity through a series of manufacturing and treatment processes. The first step in enhancing load-bearing capacity is the selection of the appropriate grade of steel. Different grades of steel have varying mechanical properties, such as yield strength and tensile strength, which directly impact load-bearing capacity. Higher strength grades, such as high-strength low-alloy (HSLA) or advanced high-strength steel (AHSS), are typically chosen for applications requiring greater load-bearing capacity. Once the steel grade is determined, the steel strips undergo a series of manufacturing processes. The strips are usually hot-rolled or cold-rolled to achieve the desired thickness and shape. Hot-rolling involves heating the steel above its recrystallization temperature and passing it through a series of rollers to reduce thickness and shape it into a strip. Cold-rolling, on the other hand, involves passing the steel through rollers at room temperature, resulting in a smoother finish and tighter tolerances. After the initial rolling process, the steel strips may undergo further treatments to enhance their load-bearing capacity. One common treatment is heat treatment, which involves heating the steel to a specific temperature and then rapidly cooling it to alter its microstructure. This process can increase the strength and hardness of the steel, improving its load-bearing capacity. Other treatments may include surface coatings or galvanization to protect the steel from corrosion, which can weaken its load-bearing capacity over time. Coatings such as zinc or epoxy can provide an extra layer of protection against environmental factors that may compromise the integrity of the steel strips. In summary, steel strips are processed for load-bearing capacity by selecting the appropriate grade of steel, followed by manufacturing processes such as hot-rolling or cold-rolling. Additional treatments like heat treatment and surface coatings may be applied to further enhance the load-bearing capacity and protect the steel from corrosion.

- Q: Are steel strips commonly used in the manufacturing of storage systems?

- Yes, steel strips are commonly used in the manufacturing of storage systems due to their strength, durability, and ability to support heavy loads.

- Q: How do steel strips contribute to reducing product defects in various applications?

- Steel strips contribute to reducing product defects in various applications by providing a strong and durable material that ensures stability and accuracy during manufacturing processes. The uniformity and consistency of steel strips help to minimize variations in product dimensions and ensure precise cutting and shaping. Additionally, their high tensile strength and resistance to deformation help prevent warping or bending, leading to improved product quality and reduced defects.

- Q: What are the different types of coatings available for steel strips?

- There are several types of coatings available for steel strips, including galvanized coatings, zinc coatings, tin coatings, polymer coatings, and paint coatings. Each type of coating offers different levels of protection against corrosion and wear, depending on the specific requirements of the application.

- Q: How are steel strips protected against electrical conductivity?

- Steel strips are protected against electrical conductivity through a process called insulation. This involves coating the steel strips with materials such as insulation tapes, coatings, or varnishes that have high electrical resistance. These insulation materials prevent the flow of electricity through the steel strips, ensuring they do not conduct electrical current.

- Q: How are steel strips tempered for improved toughness?

- Steel strips are tempered for improved toughness through a process known as heat treatment. This process involves heating the steel strips to a specific temperature, typically between 300-700 degrees Celsius, and then cooling it rapidly. This rapid cooling is done by quenching the steel in oil, water, or air, depending on the desired level of toughness. During the heating stage, the steel strips undergo a transformation known as austenitization, where the crystal structure of the steel changes. This results in the formation of a hard and brittle phase called martensite. While martensite provides high hardness, it lacks toughness and is prone to cracking under stress. To improve toughness, the steel strips are then subjected to the tempering process. During tempering, the steel strips are reheated to a lower temperature, typically between 150-300 degrees Celsius, and held at that temperature for a specific duration of time. This allows the martensite to transform into a more ductile phase called tempered martensite. The tempering process helps to relieve internal stresses within the steel strips, reduce brittleness, and improve toughness and ductility. It also allows for the adjustment of the final mechanical properties based on the specific requirements of the application. Overall, steel strips are tempered for improved toughness by subjecting them to a carefully controlled heat treatment process, which transforms the hard and brittle martensite phase into a more ductile tempered martensite phase. This ensures that the steel strips possess the desired combination of hardness and toughness for various industrial applications.

Send your message to us

This World's Best Rebar From Chines Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 22222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords