Galvanized World's Best Rebar From Chines Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 444 m.t.

- Supply Capability:

- 222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Wire Rod Steel for Construction Description

the wire rod steel for construction that we offer have been used in civil construction work for years.

2.Main Features of the Wire Rod Steel for Construction

fasteners, bolts, rivets, screws,

general purpose wires,

electrode wires, industrial wires, agriculture wires,

bush wires, chain rivet wires,

detonator wire,

Umbrella ribs, upholstery wires, cycle spokes, needle wires, heald wires, staple pin Wire, safety pin wires

ACSR wires, earth wires,

tyre and hose reinforcement wires,

prestressed concrete wire, springs and rope wires,

card clothing wires,

vineyard wires,

ball bearing quality

Automobile parts like screw, fasteners, bush, spline, socket, connecting rod, shaft, gear, rivets, engine shaft, connecting rod, spindles, gears, etc.

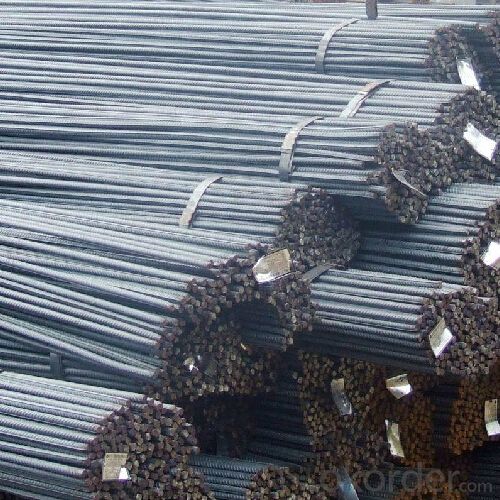

3.Wire Rod Steel for Construction Images

4.Wire Rod Steel for Construction Specification

Base metal | Cold rolled steel coil,full hard cold rolled steel coil |

Material | SGCC,SGCH, Full hard |

Grade: | Commercia.Quality(CGCC,DX51D,DC01,SPCC), Structure.quality(S280GD,S320GD,S350GD). Deep.drawing.quality(DX52D,DX53D,DX54D,DX56D) |

Standard | ASTM A653 CS/B,JIS G3302,DIN EN 10142,EN10327 |

Applications | Advertising,building trade,home electrical, Electrical industry,decoration,office furniture |

Thickness | 0.14mm-1.0mm |

Tolerance | +/-0.03mm |

Zinc layer | A40,A60,G60,G90,G115,G140,G165. Z12,Z18,Z22,Z25,Z27,Z35. Z60,Z80,Z100,Z120,Z150,Z180,Z220,Z275,Z350 |

Width | 600mm,750mm,762mm,914mm,1000mm,1219mm,1200mm,1250mm,1500mm |

Length | 1.5m,2.0m,2.438m,2.44m,2.5m,3m.,3.5m,4m,4.5m,5m |

Surface treatment | Chromated,oiled/unoiled,skinpassed,Chromated+oiled |

Surface state | Regular spangle,mini spangle,zero spangle, skinpassed |

Coil weight | 4-8tons |

ID | 508mm or 610mm |

Packing | Export standard seaworthy packing. Waterproof paper+steel sheet+bundle with steel strips(3-4pcs) |

Delivery | Based on the quantity. |

Shipment | Bulk vessel or container (FCL/LCL) |

Payment | T/T or LC at sight |

Loading port | Main port of China,Shang hai,Qingdao,Dalian,Tianjin etc. |

Yield strength | 285Mpa-305Mpa |

Tensile strength | 340Mpa-370Mpa |

5.FAQ of Wire Rod Steel for Construction

1.What is your minimum order quantity ?

Our MOQ is 500mt .

2.Please tell me the daily output and wire rod mill’s brand ?

Our daily output is 4000mt/day and our rolling mill from Germany’s SMS MEER

3.Which countries are your main sales?

Thanks to the professional international trade team, solid distribution channel and long – term cooperation customers, our market share in overseas realizes a tremendous growth, now we already became a main player in Middle East and South East Asia. Meanwhile, we are also the biggest supplier of Pre-painted galvanized steel coil in Philippines, Saudi Arabia, United Arab Emirates, Iran, Sudan etc.

- Q: How is steel used in the manufacturing of HVAC systems?

- Steel is commonly used in the manufacturing of HVAC systems for its strength, durability, and ability to withstand high temperatures. It is used in various components such as air ducts, heat exchangers, and furnace enclosures, ensuring the system's structural integrity and longevity.

- Q: What are the applications of steel in the petrochemical industry?

- Steel has numerous applications in the petrochemical industry due to its exceptional strength, durability, and resistance to extreme temperatures and corrosive environments. It is extensively used in the construction of storage tanks, pipelines, and equipment for the processing and transportation of petrochemicals. Additionally, steel is utilized in the fabrication of heat exchangers, reactors, and furnaces, where it plays a crucial role in maintaining operational efficiency and safety.

- Q: How is steel used in the production of process equipment for chemical plants?

- Steel is commonly used in the production of process equipment for chemical plants due to its strength, durability, and resistance to corrosion. It is used to construct various components such as tanks, pipes, valves, and reactors, which are crucial for storing and transporting chemicals throughout the plant. Additionally, steel's high melting point makes it suitable for handling high temperatures and pressures that are often encountered in chemical processes.

- Q: How is steel tubing used in the manufacturing of hydraulic cylinders?

- Steel tubing is commonly used in the manufacturing of hydraulic cylinders as it provides a strong and durable structure for fluid transfer and pressure containment. The tubing is formed into the desired shape and size, then welded or seamless to ensure a leak-free connection. It serves as the cylinder's main body, housing the piston and seals, and allows hydraulic fluid to flow smoothly, enabling efficient operation of the cylinder.

- Q: What are the different types of steel forgings and their applications in the defense industry?

- There are three main types of steel forgings used in the defense industry: carbon steel forgings, alloy steel forgings, and stainless steel forgings. Carbon steel forgings are known for their strength and durability, making them suitable for various applications in defense, such as weapon components, tank tracks, and armor plating. Alloy steel forgings are made by adding various alloying elements to carbon steel, enhancing their strength, toughness, and resistance to wear and corrosion. These forgings are commonly used in critical defense components like aircraft landing gear, missile parts, and submarine propellers. Stainless steel forgings, on the other hand, are highly resistant to corrosion and have excellent mechanical properties. These forgings find applications in the defense industry, particularly in naval vessels, submarines, and aircraft carriers, where they are used for valves, pumps, shafts, and other critical components. Overall, steel forgings play a vital role in the defense industry by providing the required strength, durability, and performance needed for various defense applications, ensuring the safety and reliability of military equipment.

- Q: How do steel products contribute to the retail and commercial sector?

- Steel products contribute to the retail and commercial sector in various ways. Firstly, they are widely used in the construction industry for building structures, such as shopping malls, office buildings, and warehouses. Steel's strength, durability, and versatility make it a preferred choice for constructing large commercial spaces. Additionally, steel products are used to create shelving units, display racks, and storage systems in retail stores. These products provide a sturdy and reliable solution for organizing and displaying merchandise, ensuring efficient use of space and enhancing the overall shopping experience for customers. Moreover, steel is commonly used in the manufacturing of commercial equipment and fixtures, including cash registers, shopping carts, and display stands. These steel products offer durability and stability, ensuring the smooth operation of retail and commercial businesses. Furthermore, steel plays a vital role in the transportation and logistics sector. Steel containers, shipping pallets, and storage racks are essential in facilitating the movement and storage of goods in warehouses, distribution centers, and retail outlets. Overall, steel products are crucial for the retail and commercial sector as they provide the necessary infrastructure, equipment, and fixtures required for smooth and efficient operations, contributing to the growth and success of businesses in this sector.

- Q: What are the different types of steel products used in the manufacturing of luxury goods?

- The different types of steel products used in the manufacturing of luxury goods include stainless steel, Damascus steel, and carbon steel. Stainless steel is a popular choice due to its corrosion resistance and durability. Damascus steel is known for its unique pattern and high strength, making it a favored material for luxury knives and jewelry. Carbon steel is valued for its hardness and edge retention, commonly used in high-end chef knives and timepieces.

- Q: What are the different types of steel chains and their uses in lifting equipment?

- There are primarily three types of steel chains used in lifting equipment: alloy steel chains, carbon steel chains, and stainless steel chains. Alloy steel chains are incredibly strong and durable, making them suitable for heavy-duty lifting applications. Carbon steel chains are more affordable and offer decent strength, making them commonly used in medium-duty lifting tasks. Lastly, stainless steel chains are corrosion-resistant and often used in industries where exposure to moisture or chemicals is expected. Each type of steel chain has distinct properties that make them suitable for specific lifting needs.

- Q: What are the different types of steel sheets and their uses in the construction of prefabricated buildings?

- There are several types of steel sheets commonly used in the construction of prefabricated buildings. These include cold-rolled steel sheets, hot-rolled steel sheets, galvanized steel sheets, and stainless steel sheets. Cold-rolled steel sheets are known for their smooth finish and high strength. They are commonly used in the construction of walls, roofs, and floors in prefabricated buildings due to their excellent durability and resistance to corrosion. Hot-rolled steel sheets are known for their superior strength and versatility. They are often used in the construction of structural components, such as beams and columns, in prefabricated buildings. Galvanized steel sheets are coated with a layer of zinc to protect them from corrosion. These sheets are commonly used in the construction of prefabricated buildings where exposure to moisture or harsh weather conditions is a concern, such as in coastal areas or industrial settings. Stainless steel sheets are highly resistant to corrosion and have excellent mechanical properties. They are commonly used in the construction of prefabricated buildings in environments where hygiene and durability are crucial, such as hospitals, laboratories, and food processing facilities. Overall, the different types of steel sheets used in the construction of prefabricated buildings provide a range of options to meet specific requirements for strength, durability, corrosion resistance, and aesthetic appeal.

- Q: What is the role of steel in the infrastructure development?

- The role of steel in infrastructure development is crucial as it provides strength, durability, and flexibility to various structures such as bridges, buildings, and highways. Steel's high tensile strength allows for the construction of taller and larger structures, ensuring their stability and safety. Additionally, steel is resistant to corrosion, making it suitable for withstanding harsh weather conditions and extending the lifespan of infrastructure. Its versatility and recyclability also contribute to cost-effectiveness and sustainability in construction projects. Overall, steel plays a vital role in the development of resilient and long-lasting infrastructure.

Send your message to us

Galvanized World's Best Rebar From Chines Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 444 m.t.

- Supply Capability:

- 222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords