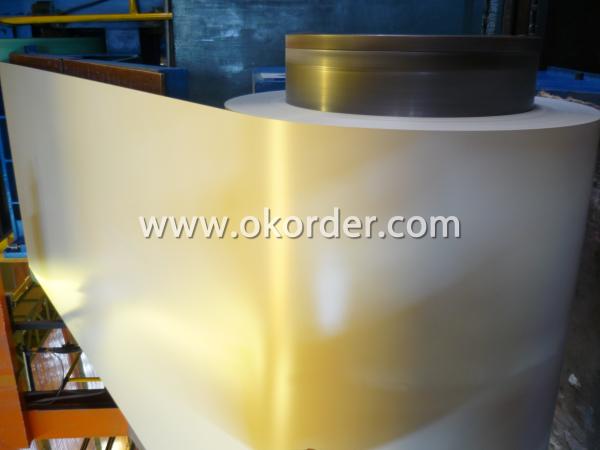

Best Quality for White Prepainted Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 10000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of White Prepainted Galvanized Steel

With GI as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Specification of White Prepainted Galvanized Steel:

1. Thickness 0.23-1.2mm (BMT)

2. Zinc Coating 80-275g/m2

3. Color According to RAL color fan Internal

4. Diameter 508mm or 610mm

5. Coil Weight 4-8MT

6. Quality Commercial and structural quality

7. Paint Polyester paint for topside, epoxy for reverse

8. Standard JIS G 3312, ASTM A755M, EN 10169

9. Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS

Chemical Composition of White Prepainted Galvanized Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data of White Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Application of White Prepainted Galvanized Steel

Outdoor:

roof, roof structure, surface sheet of balcony,

frame of window, door, door of garage, roller shutter door, booth, Persian blinds, cabana, etc.

In door:

door, isolater, frame of door, light steel structure of house, home electronic appliances, etc.

Packaging & Delivery of White Prepainted Galvanized Steel

Anti-damp paper inside full wrapped with plastic film, iron sheet outside on wooden pallet in 20 feet container with 25mt.

- Q: What are the different types of steel rods and their applications?

- There are several types of steel rods available, each with its own unique properties and applications. Some common types include carbon steel rods, stainless steel rods, and alloy steel rods. Carbon steel rods are widely used in construction and manufacturing due to their high strength and durability. Stainless steel rods are resistant to corrosion and are often used in industries such as food processing and medical equipment manufacturing. Alloy steel rods, on the other hand, are designed to have specific mechanical properties such as increased hardness or improved heat resistance, making them suitable for applications in automotive and aerospace industries. Overall, the choice of steel rod depends on the specific requirements and environment of the application.

- Q: What are the different types of steel storage systems used in warehouses?

- There are several types of steel storage systems commonly used in warehouses, including pallet racking systems, cantilever racks, drive-in racks, and mezzanine floors. Pallet racking systems are versatile and can efficiently store large quantities of palletized goods. Cantilever racks are ideal for storing long and bulky items such as pipes or lumber. Drive-in racks allow for high-density storage by allowing forklifts to drive directly into the racks. Mezzanine floors create additional storage space by utilizing the vertical height of the warehouse, providing additional levels of storage.

- Q: How is steel used in the construction of industrial buildings and warehouses?

- Steel is commonly used in the construction of industrial buildings and warehouses due to its strength, durability, and cost-effectiveness. It is used for structural frames, beams, columns, and trusses, providing a sturdy framework that can support heavy loads and withstand harsh environmental conditions. Additionally, steel allows for larger open floor plans and flexible layouts, making it easier to customize the interior space to meet specific requirements.

- Q: How is steel sheet metal stamped for automotive parts?

- Steel sheet metal is stamped for automotive parts through a process called sheet metal stamping. This involves using specialized machines and tooling to cut, bend, and shape the steel into the desired automotive component. The process typically includes steps such as blanking, piercing, forming, and trimming to achieve the required shape and dimensions.

- Q: What are the factors that affect the price of steel products?

- There are several factors that can influence the price of steel products, including the cost of raw materials, such as iron ore and coal, which are used in the manufacturing process. Additionally, fluctuations in global supply and demand, changes in government policies and regulations, currency exchange rates, and overall economic conditions can also impact steel prices. Other factors that may affect the price include transportation costs, energy prices, and the level of competition within the steel industry.

- Q: What are the different types of steel products used in the manufacturing of sports equipment?

- The different types of steel products used in the manufacturing of sports equipment include steel bars, tubes, sheets, and wires. These steel products are used to create various components such as frames, shafts, handles, and support structures that provide strength, durability, and flexibility to sports equipment like bicycles, golf clubs, tennis rackets, and baseball bats.

- Q: How is steel billet produced?

- Steel billet is produced through a process called continuous casting, which involves melting scrap steel in an electric arc furnace and then pouring the molten steel into a water-cooled mold. As the steel cools, it solidifies into a semi-finished rectangular shape called a billet, which can be further processed into various steel products.

- Q: How is steel used in the construction of power plants?

- Steel is used extensively in the construction of power plants due to its strength, durability, and high melting point. It is utilized for various components such as structural frames, support beams, turbine casings, and pressure vessels. Steel's ability to withstand high temperatures, pressures, and harsh environmental conditions makes it an ideal material for power plant infrastructure, ensuring the safety and reliability of these facilities.

- Q: How are steel sheets used in roofing and cladding systems?

- Steel sheets are commonly used in roofing and cladding systems due to their durability, strength, and resistance to weathering. They are typically used as the outer layer or covering of roofs and walls to protect the building from the elements. Steel sheets are easy to install, can be customized to various shapes and sizes, and require minimal maintenance. They provide a long-lasting and aesthetically pleasing solution for both residential and commercial buildings.

- Q: How does steel pipe welding work?

- Steel pipe welding works by using heat to melt the edges of the pipes, creating a molten pool. A filler material is then added to the pool, which fuses the edges of the pipes together when it cools and solidifies. This process, known as fusion welding, creates a strong and durable bond between the pipes, ensuring a secure and leak-proof connection.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2003 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Southern Asia; America; South America; Eastern Europe |

| Company Certifications | ISO 9000 ISO 14000 OHSAS 18000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 200,000 square meters |

| No. of Production Lines | 14 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for White Prepainted Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 10000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords