Best Quality for Prepainted Galvanized Steel - Red

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 20000 Metric Tons Per Month c Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

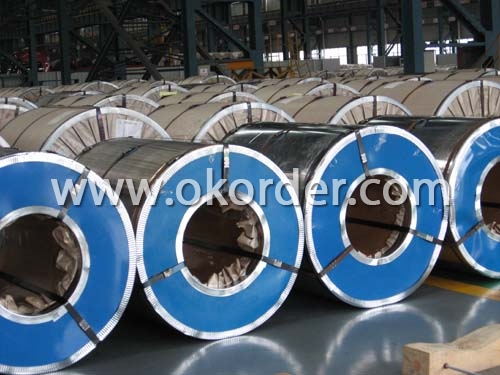

General Information Of Prepainted Galvanized Steel Coil

With GI as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

|

Thickness 0.23-1.2mm (BMT) |

|

Width 900-1250mm |

|

Zinc Coating 80-275g/m2 |

|

Color According to RAL color fan |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 3-8MT |

|

Quality Commercial and structural quality |

|

Paint Polyester paint for topside, epoxy for reverse |

|

Standard JIS G 3312, ASTM A755M, EN 10169 |

|

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Prepainted Galvanized Steel Coil

|

C |

Si |

Mn |

P |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel Coil

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Reverse Impact |

9J |

|

T-bending |

≥2T |

|

Pencil Hardness |

≥2H |

|

Duration Of Salt Spray Test |

500 H |

|

Bending At 180 Degree |

No crack, purling and fraction |

Application Of Prepainted Galvanized Steel Coil

Outdoor:

roof, roof structure, surface sheet of balcony,

frame of window, door, door of garage, roller shutter door, booth, Persian blinds, cabana, etc.

In door:

door, isolater, frame of door, light steel structure of house, home electronic appliances, etc.

Packaging & Delivery Of Prepainted Galvanized Steel Coil

Anti-damp paper inside full wrapped with plastic film, iron sheet outside on wooden pallet in 20 feet container with 25mt.

- Q:What are the different types of steel pipes and tubes available?

- There are several different types of steel pipes and tubes available, including seamless, welded, galvanized, stainless steel, and carbon steel pipes. Each type has its own unique properties and uses, making them suitable for various applications in industries such as construction, plumbing, oil and gas, and manufacturing.

- Q:What are the different types of steel stair treads and nosings?

- There are several types of steel stair treads and nosings available, including diamond plate treads, serrated treads, perforated treads, and abrasive nosings. Each type offers specific benefits such as slip resistance, durability, and ease of maintenance, catering to various safety and aesthetic requirements in different environments.

- Q:What are the properties and characteristics of stainless steel?

- Stainless steel is a corrosion-resistant alloy that contains a minimum of 10.5% chromium, which forms a passive layer on the surface, preventing further oxidation. It is known for its high strength, durability, and heat resistance, making it suitable for various applications. Stainless steel is also easy to clean, non-magnetic, and has excellent hygiene properties, making it ideal for use in the food and medical industries. It is available in different grades, each with specific properties, such as increased corrosion resistance or improved strength, to suit different applications.

- Q:What are the different types of steel beams used in building structures?

- There are several types of steel beams commonly used in building structures, including I-beams, H-beams, and wide flange beams. I-beams, also known as W-beams, have a cross-section shaped like the letter "I" and are commonly used in residential and commercial construction. H-beams, also known as H-shaped beams, have a cross-section shaped like the letter "H" and are often used in bridge construction. Wide flange beams, also known as W-flange beams, have a wider flange than I-beams and are commonly used in industrial and commercial construction.

- Q:How is steel used in the production of railway tracks?

- Steel is commonly used in the production of railway tracks due to its strength, durability, and ability to withstand heavy loads and harsh weather conditions. The steel rails provide a stable and smooth surface for trains to travel on, ensuring a safe and efficient transportation system.

- Q:What are the uses of steel wire mesh?

- Steel wire mesh has a wide range of uses, including reinforcing concrete structures, providing security in fencing and gates, preventing animals from entering certain areas, filtering and sieving materials, supporting and reinforcing walls and ceilings, and creating partitions or barriers in construction and industrial applications.

- Q:What are the different types of steel products used in the manufacturing of tools and machinery?

- There are several types of steel products used in the manufacturing of tools and machinery. Some common examples include carbon steel, alloy steel, stainless steel, and tool steel. Carbon steel is widely used due to its strength and affordability. Alloy steel contains additional elements such as chromium, nickel, and molybdenum to enhance specific properties like hardness and corrosion resistance. Stainless steel is favored for its resistance to rust and staining, making it suitable for tools and machinery used in moisture-prone environments. Tool steel is specifically designed for tool-making, offering high hardness, wear resistance, and toughness.

- Q:What are the different types of steel coatings for fire resistance?

- There are several types of steel coatings that are used for fire resistance, including intumescent coatings, cementitious coatings, and ablative coatings. Intumescent coatings are designed to expand when exposed to heat, forming an insulating char layer that protects the steel from high temperatures. Cementitious coatings are made of cement, aggregates, and additives, providing a dense and fire-resistant layer on the steel. Ablative coatings are designed to release a gas or vapor when exposed to heat, creating a protective barrier against fire. These coatings vary in their application methods, thickness, and performance characteristics, providing different levels of fire resistance for steel structures.

- Q:How is steel plate formed into complex shapes?

- Steel plate can be formed into complex shapes through various processes such as bending, rolling, and pressing. These techniques involve applying force and pressure to the steel plate, which allows it to be molded and shaped according to the desired design.

- Q:How does steel sheet metal cutting and punching work?

- Steel sheet metal cutting and punching typically involve using specialized machinery, such as lasers, plasma cutters, or mechanical presses, to cut or punch holes in steel sheet metal. The process begins with the metal sheet being secured onto a flat surface or within the machine. The cutting or punching tool is then guided across the sheet, applying focused force or energy to remove material and create the desired shape or hole. This process can be precise and efficient, allowing for the fabrication of various steel components used in industries like construction, automotive, and manufacturing.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 1999 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Europe; Africa; Mid East; Southeast Asia |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 50-80 |

| Language Spoken: | Chinese, English |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for Prepainted Galvanized Steel - Red

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 20000 Metric Tons Per Month c Tons Per Month m.t./month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords