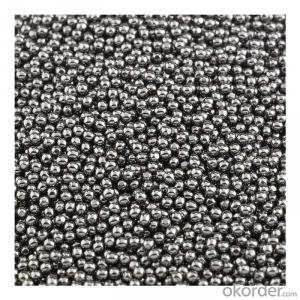

SUS420 G100 8mm Steel Shot SGS Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

420

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

Product Description

THE DETAIL OF STAINLESS STEEL BALL| Product | Stainless steel ball |

| Material | stainless steel |

| Brand | SAIGE |

| Percision | G100 |

| Hardness | HRC>52 |

| Surface | zero defect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

| Certification | ISO9100;2008SGS |

Products Picture

Stainless steel (AISI 420)

AISI 420 have good hardness and fair-to-good corrosion resistance and strength, it is generally used for all applications requiring resistance to corrosion such as bearings, valves, writting instruments, food environment, fresh water, many petroleum products and mild acid environments. AISI 420 is also magnetic.AISI 420 stainless steel balls in our factory:

Minimum diameter :1.2mm

Best precision :G10

Hardness :HRc>52

THE ADVENTAGE OF STAINLESS STEEL BALL

A, The strict process of stainless steel ball

Raw material--Wire drawing--Cold heading--Flashing--Heat treament--Grinding--Lapping 1--Lapping2--Lapping3--Washing--Checking. All balls must be passed the procedure of passivation. Each procedure have professional inspector. They will check steel balls each two hours to be sure correct diameter and good surface.

B, Sample Free

If you are interested in our product ,we can send you our free sample for you . Please contact us as soon as possible.

- Q: How is steel used in the construction of bridges?

- Steel is commonly used in the construction of bridges due to its high strength and durability. It is often used to create the main structural elements of the bridge, such as beams, girders, and trusses. Steel's ability to withstand heavy loads and resist corrosion makes it an ideal material for supporting the weight of the bridge and ensuring its long-term stability. Additionally, steel can be easily fabricated and assembled, allowing for efficient construction and maintenance of bridges.

- Q: How is steel sheet formed and shaped?

- Steel sheet is formed and shaped through a process called hot rolling, where a large metal slab is heated and passed through a series of rolling mills to gradually reduce its thickness and shape it into a sheet. The hot rolling process involves high temperatures and pressure, which allows the steel to become more malleable and easily manipulated into the desired shape. Additionally, cold rolling can be employed to further refine the sheet's surface finish and dimensions.

- Q: How does the thickness of steel affect its strength?

- The thickness of steel directly affects its strength. Generally, thicker steel tends to be stronger and more resistant to deformation or failure under load. This is because thicker steel has a greater cross-sectional area, which allows it to distribute and withstand forces more effectively. Thicker steel also provides a larger volume for the material to absorb energy before reaching its breaking point. However, it is important to note that there is a trade-off between thickness and other factors such as weight and cost, so the optimal thickness depends on the specific application and requirements.

- Q: What are the different types of steel tanks and containers available?

- There are several types of steel tanks and containers available, including above-ground storage tanks, underground storage tanks, pressure vessels, intermediate bulk containers (IBCs), and shipping containers. Each type serves a specific purpose and is designed to meet different storage or transportation needs.

- Q: How is steel sheet metal formed?

- Steel sheet metal is formed through a process called cold rolling, where the steel is passed through a series of rollers to reduce its thickness and shape it into a flat sheet. This process involves applying pressure and tension to the steel, altering its structure and creating the desired shape.

- Q: What are the different types of steel hinges and hardware available?

- There are several different types of steel hinges and hardware available, including butt hinges, continuous hinges, piano hinges, strap hinges, pivot hinges, gate hinges, and cabinet hinges. Each type of hinge has its own unique design and functionality, making it suitable for specific applications and requirements. Additionally, there are various hardware options such as screws, bolts, latches, handles, and brackets that complement the hinges and provide additional support and functionality.

- Q: What are the properties of carbon steel for industrial use?

- Carbon steel is a popular choice for industrial use due to its excellent strength, durability, and affordability. It is primarily composed of iron and carbon, with varying levels of other alloying elements. Carbon steel possesses high tensile strength, making it suitable for applications that require heavy loads or structural integrity. It also exhibits good machinability and weldability, allowing for easy fabrication and modification. Additionally, carbon steel can be hardened and tempered to enhance its hardness and wear resistance. However, it is susceptible to corrosion, so appropriate protective coatings or treatments are often applied in industrial settings to prevent rust and degradation.

- Q: What are the different types of steel bolts and their uses in the construction of power plants?

- There are several types of steel bolts commonly used in the construction of power plants. The most common ones include structural bolts, anchor bolts, and flange bolts. Structural bolts are used to connect heavy structural members, such as steel beams and columns, to provide stability and support. These bolts are typically high-strength and have a larger diameter to withstand heavy loads and vibrations. Anchor bolts are used to secure equipment and machinery to the concrete foundation in power plants. They are designed to provide stability and prevent movement or shifting of the equipment during operation. Anchor bolts are often embedded in the foundation and have threaded ends to attach nuts and washers. Flange bolts are used to connect piping systems, valves, and flanges in power plants. They have a washer-like flange under the head, which distributes the load and prevents leakage. Flange bolts are available in various grades and sizes, depending on the specific requirements of the application. In summary, the different types of steel bolts used in the construction of power plants serve distinct purposes. Structural bolts provide stability to heavy structural members, anchor bolts secure equipment to the foundation, and flange bolts connect piping systems and prevent leakage.

- Q: What are the advantages of using steel in the construction of sports stadiums?

- There are several advantages of using steel in the construction of sports stadiums. Firstly, steel is a highly durable material, capable of withstanding heavy loads and extreme weather conditions. This ensures the long-term safety and structural integrity of the stadium. Secondly, steel offers great flexibility in design, allowing architects to create unique and innovative stadium structures. Additionally, steel is lightweight compared to other construction materials, which simplifies the construction process and reduces costs. Furthermore, steel is a sustainable and environmentally friendly choice, as it is often made from recycled materials and can be easily recycled at the end of its lifespan. Overall, these advantages make steel an ideal choice for constructing sports stadiums.

- Q: What is the process of steel galvanization?

- The process of steel galvanization involves immersing the steel in a bath of molten zinc or applying a zinc coating to the steel through a hot-dip or electroplating method. This forms a protective layer of zinc on the surface of the steel, preventing rust and corrosion and increasing its durability.

Send your message to us

SUS420 G100 8mm Steel Shot SGS Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords