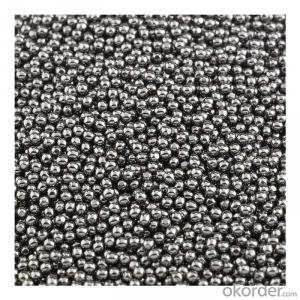

SUS420 G100 8mm Metal Balls RoHS Stainless Steel Shot Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

| Product | AISI420 G100 All Sizes Steel Shot Stainless Steel Ball |

| Material | stainless steel |

| Pericision | G100 |

| Hardness | HRC25-39 |

| Surface | zero defect , bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Safe | ROHS |

| Package | four small boxes within a carton of 20kg |

Products Picture

Strict process

our company have the strict process :Raw material--Wire drawing--Cold heading--Flashing--Heat treatment--Grinding--Lapping1--Lapping2--Lapping3--Washing--Checking--Packing

High efficiency / High efficiency inspection

Our production capacity is 160 tons per month. we have the high quality testing instruments

for example : roundness measuring equipment , photometric sorter, metallographic structure detector, vibroscope,salt spray tester.

Green product

Our company product are all passed the ISO and SGS certification .

Competitive price: We are a direct steel ball manufacture, lower price is possible

Advanced production flow: With our more than 20 years experience, we have explored compelete production flow, high quality has become an advantage.

Discount: Since we are steel ball foctory, we would like larger quantity, so we will provide suitable discount according to your quantity.

- Q: What are the properties of heat-treated steel?

- Heat-treated steel has several properties that make it desirable for various applications. Firstly, it has improved hardness and strength compared to untreated steel. This is achieved by subjecting the steel to controlled heating and cooling processes, which alter its microstructure and result in a more durable material. Heat-treated steel also exhibits enhanced wear resistance, making it suitable for applications that involve friction or abrasion. Additionally, it often possesses improved toughness, allowing it to withstand impact and sudden loads. The specific properties of heat-treated steel can vary depending on the specific heat treatment method used, such as quenching and tempering, but generally, it offers a combination of high strength, hardness, wear resistance, and toughness.

- Q: How is steel tubing used in the manufacturing of automobile exhaust systems?

- Steel tubing is used in the manufacturing of automobile exhaust systems because it offers strength, durability, and resistance to high temperatures and corrosion. The tubing is shaped and welded to form the necessary paths for exhaust gases to flow from the engine to the tailpipe, ensuring efficient and safe removal of harmful emissions.

- Q: How is steel used in the production of textile machinery?

- Steel is used in the production of textile machinery for various purposes such as constructing the machine frame, gears, and shafts, as well as providing structural support and durability to handle the heavy loads and high speeds involved in textile manufacturing processes.

- Q: How are steel tubes used in the fabrication of hydraulic systems?

- Steel tubes are commonly used in the fabrication of hydraulic systems due to their strong and durable properties. They are used to transport hydraulic fluids and withstand the high pressure and temperature conditions within the system. Steel tubes provide a reliable and leak-free connection between various hydraulic components, such as pumps, valves, and actuators, ensuring smooth operation and efficient power transmission.

- Q: What are the different types of steel reinforcing bars?

- There are various types of steel reinforcing bars, commonly known as rebar, used in construction. These include carbon steel rebars, epoxy-coated rebars, stainless steel rebars, and galvanized rebars. Each type possesses unique characteristics and is selected based on the specific requirements of the construction project.

- Q: How is steel rebar used in concrete construction?

- Steel rebar, also known as reinforcing bar, is used in concrete construction to provide additional strength and stability to the concrete structures. It is placed within the concrete forms prior to pouring the concrete and acts as a reinforcement by absorbing tension forces and preventing cracks and failures. The rebar is strategically positioned to distribute the load evenly and enhance the overall structural integrity of the concrete.

- Q: How do steel products contribute to the construction of research laboratories and scientific facilities?

- Steel products play a crucial role in the construction of research laboratories and scientific facilities. They provide structural support and durability, ensuring the safety and integrity of the buildings. Steel beams, columns, and frames are commonly used to create large open spaces, allowing for flexible layouts and accommodating various equipment and machinery. Additionally, steel is resistant to fire, corrosion, and pests, making it an ideal choice for laboratories where hazardous materials and sensitive experiments are conducted. Overall, steel products are essential components in creating efficient, functional, and secure research facilities.

- Q: How are steel forgings used in the production of power generation equipment?

- Steel forgings are used in the production of power generation equipment due to their strength, durability, and ability to withstand high temperatures and pressures. They are commonly used in critical components such as turbine blades, rotors, and shafts, ensuring the reliable and efficient operation of power plants. The forging process enhances the structural integrity of the steel, making it resistant to fatigue and wear, thereby extending the lifespan and performance of the equipment.

- Q: What are the different types of steel wires and their uses?

- There are several types of steel wires, including carbon steel wire, stainless steel wire, and galvanized steel wire. Carbon steel wire is commonly used for general-purpose applications such as fencing, construction, and automotive manufacturing. Stainless steel wire, known for its corrosion resistance, is often used in industries like aerospace, medical equipment, and food processing. Galvanized steel wire is coated with zinc to enhance its corrosion resistance and is commonly used for agricultural purposes, wire mesh, and electrical applications.

- Q: What are the different types of steel meshes and their applications?

- There are several types of steel meshes, each with its own unique characteristics and applications. 1. Welded Wire Mesh: This type of mesh consists of welded intersections, creating a rigid and strong structure. It is commonly used in construction projects for concrete reinforcement, fencing, and animal enclosures. 2. Expanded Metal Mesh: Made by cutting and stretching a metal sheet, this mesh has a diamond-shaped pattern. It is used in architectural applications, such as building facades, walkways, and filtration systems. 3. Woven Wire Mesh: Constructed through interlacing wires, this type of mesh is available in various patterns and sizes. It finds applications in industries like agriculture, mining, and filtration, where it is used for screening, sieving, and separating materials. 4. Perforated Metal Mesh: It is created by punching holes into a metal sheet, resulting in a pattern of regularly spaced openings. This mesh is widely used in industries like HVAC, automotive, and architecture for air ventilation, acoustic panels, and decorative purposes. 5. Wire Cloth: Composed of woven wires, wire cloth is used for a wide range of applications, including filtration, insect screening, and sieving. It is commonly found in industries such as food processing, chemical processing, and mining. These are just a few examples of steel meshes, and their applications are vast and diverse. The choice of mesh type depends on the specific requirements of the application, including strength, durability, aesthetics, and functionality.

Send your message to us

SUS420 G100 8mm Metal Balls RoHS Stainless Steel Shot Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords