Stainless Steel Balls

Stainless Steel Balls Related Searches

Stainless Steel Ball Stainless Steel Ball Chain Stainless Steel Gazing Ball Stainless Steel Ball Stretcher Stainless Steel Hoops Stainless Steel Baskets Stainless Steel Bars Stainless Steel Beads Stainless Steel Basket Stainless Steel Elements Stainless Steel Bangles Stainless Steel Tubes Stainless Steel Blanks Stainless Steel Rods Stainless Steel Legs Stainless Steel Flasks Stainless Steel Studs Stainless Steel Metals Stainless Steel Block Stainless Steel Tanks Stainless Steel Cloths Stainless Steel Strips Stainless Steel Chains Stainless Steel Canisters Stainless Steel Wall Stainless Steel Doors Stainless Steel Glasses Stainless Steel Boxes Stainless Steel Shot Stainless Steel GlovesStainless Steel Balls Supplier & Manufacturer from China

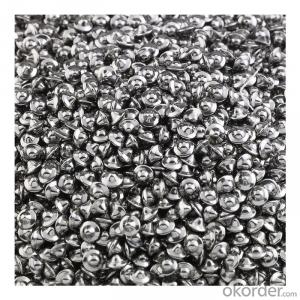

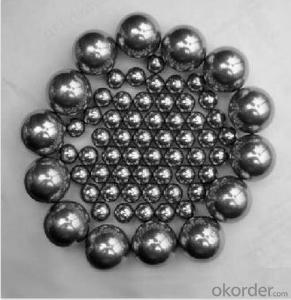

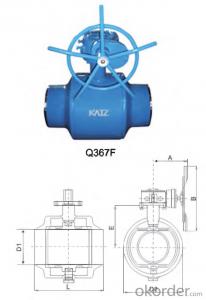

Stainless steel balls are precision balls made from stainless steel material, known for their excellent corrosion resistance, wear resistance, and dimensional accuracy. These balls are widely used in various industries due to their superior properties, including the aerospace, automotive, food processing, and medical sectors. They are utilized in a variety of applications such as bearings, valves, pumps, and other mechanical components that require smooth operation and resistance to harsh environments.Stainless steel balls are highly sought after for their ability to maintain performance under extreme conditions, making them ideal for use in demanding environments where standard materials may fail. They are also valued for their ability to withstand high temperatures and pressures, which is crucial in many industrial processes. Additionally, stainless steel balls are often chosen for their low friction coefficient and resistance to chemical corrosion, ensuring long-lasting performance and reliability.

As a leading wholesale supplier, Okorder.com offers a vast inventory of stainless steel balls, catering to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that each stainless steel ball meets the highest standards of precision and durability. This extensive inventory allows customers to find the exact specifications they require, whether it's for a specific machinery component or a larger industrial project.

Hot Products