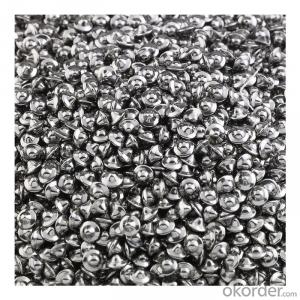

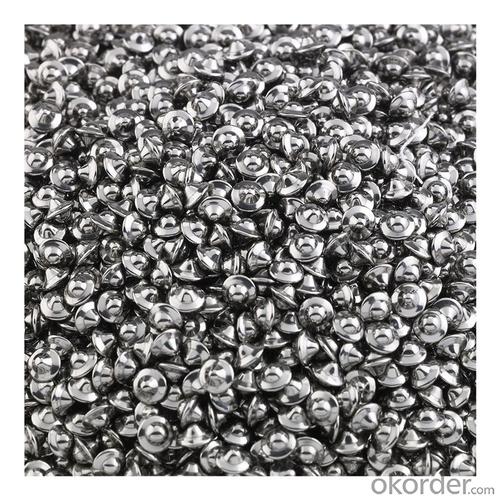

AISI316 Stainless Steel Shot Ball for Grinding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

AISI316 Stainless Steel Shot Ball for Grinding

1. Austenitic stainless steel ball with higher corrosion resistance than AISI304 balls.

2. Shows good hardness.

3. AISI316L has a lower carbon content.(maximum 0.03%)

4. Balls are provided in the passivated condition.

5.International standard:

X5CrNiMo1712 / 316 / 1.4401 / Z6CND17.11 / 08KH16N11M3 / 0Cr17Ni12Mo2

6. Applications:

Special bearings, pumps and valves, aerosol and dispenser sprayers, utilised in the foodstuff, paper, chemical, rubber, Military, textile industry, applications in photographic devices, Medical instruments, quick couplings, recirculating balls, ink cartridges, jewels.

| Stainless steel ball AISI 316L | |||||||||

| 1. Material | AISI 316L/ JIS SUS 316L/ Wks 1.4404 | ||||||||

| 2. Size Range | 1mm-180mm | ||||||||

| 3. Grade | G40-1000 | ||||||||

| 4. Hardness | 25-39 HRC | ||||||||

| 5. Characteristic | (a)Excellent resistance to corrosion(apart of chloridric acids) (b)Not hardenable austenitic inox (c)Material 1.4404 has a higher corrosion resistance than material 1.4401 | ||||||||

| 6. Magnetic | NO | ||||||||

| 7. Application | Photographic chemicals, bleaches, dyes, inks and nitric aicds Vggressive applications without mechanical efforts | ||||||||

| 8. Chemical composition | |||||||||

| C% | Si% | Mn% | Cr% | Ni% | Mo% | P% | S% | N% | |

| min. | --- | --- | --- | 16.5 | 10.0 | 2.0 | --- | --- | --- |

| max. | 0.03 | 1.00 | 2.00 | 18.5 | 13.0 | 2.5 | 0.045 | 0.015 | 0.11 |

| 9.Packing | Standard: 10kg or 20kg per carton, 1 ton per pallet or as customer required | ||||||||

| 10.Conditioning | dry or oiled | ||||||||

| 11.Delivery time | Stock within a short time or 35 days. | ||||||||

- Q: What are the different types of steel staircases and handrails?

- There are several types of steel staircases and handrails available, including straight staircases, spiral staircases, and floating staircases. Handrails can be simple and straight, or they can feature decorative elements such as scrolls or twists. Additionally, there are options for different finishes and materials, such as brushed steel or powder-coated finishes.

- Q: How are steel products used in the manufacturing of consumer goods?

- Steel products are used in the manufacturing of consumer goods in various ways, such as in the production of appliances like refrigerators, washing machines, and ovens, as well as in the construction of automobiles, bicycles, and furniture. Steel's durability, strength, and versatility make it an ideal material for these applications, providing stability, safety, and longevity to the final products.

- Q: What are the common types of steel products used in the agricultural industry?

- Common types of steel products used in the agricultural industry include fencing, gates, barns, sheds, silos, livestock equipment, and machinery such as tractors and plows.

- Q: How do steel products contribute to the automotive racing industry?

- Steel products contribute to the automotive racing industry in various ways. Firstly, steel is used in the construction of race car frames, providing the necessary strength and rigidity to withstand high speeds and intense forces. Steel components such as suspension systems, brakes, and exhaust systems also enhance performance and safety. Additionally, steel is utilized in the manufacturing of race tracks, grandstands, and infrastructure, ensuring a secure environment for both drivers and spectators. Overall, steel products play a crucial role in advancing the performance, durability, and safety standards of the automotive racing industry.

- Q: How are steel products used in the mining industry?

- Steel products are widely used in the mining industry for various purposes such as constructing infrastructure, machinery, and equipment. Steel is used to build mine shafts, pipelines, buildings, and bridges, providing the necessary structural integrity and durability. Additionally, steel is employed in the fabrication of mining equipment like drill bits, crushers, and conveyor systems, which require robust materials to withstand the harsh conditions of mining operations. Overall, steel products play a vital role in supporting the mining industry's infrastructure and ensuring efficient and safe extraction processes.

- Q: How are steel profiles used in the construction of underground tunnels?

- Steel profiles are commonly used in the construction of underground tunnels for structural support and stability. These profiles, typically in the form of beams or columns, are installed to reinforce the tunnel walls and prevent collapse. They provide strength and rigidity, helping to distribute the weight of the surrounding soil or rock and withstand external forces such as ground pressure. Additionally, steel profiles can be used to create the framework for tunnel formwork, allowing for the efficient casting of concrete walls or lining. Overall, steel profiles play a crucial role in ensuring the safety and durability of underground tunnels.

- Q: What are the different types of steel rails and their applications?

- There are several types of steel rails commonly used in various applications. Some of the most common types include: 1. Light rails: These rails are typically used in light-duty applications, such as tramways, narrow gauge railways, or temporary tracks. They are relatively lightweight and offer flexibility for installation and maintenance. 2. Heavy rails: Heavy rails are designed for high-load applications, such as mainline railways or heavy industrial tracks. They are more robust and can withstand heavy traffic and large loads over long distances. 3. Crane rails: These rails are specifically designed for crane tracks and overhead cranes. They are constructed to handle the dynamic loads and stresses imposed by cranes, ensuring smooth movement and stability. 4. Grooved rails: Grooved rails are commonly used in urban transit systems, such as trams or light rail vehicles. They have a groove along the top surface that guides the wheels, providing additional stability and preventing derailments. 5. Flat-bottomed rails: These rails are widely used in standard railway tracks. They have a flat base that rests on the sleepers, providing stability and support for heavy trains. Flat-bottomed rails are typically used in mainline railways and high-speed tracks. 6. Switch and crossing rails: These rails are used at railway switches and crossings, where trains can change tracks or cross paths. They are designed with specific profiles to ensure smooth transitions and safe operations for trains. The applications of these steel rails vary depending on the specific type and its characteristics. However, they are crucial components in the construction of railway systems, tramways, industrial tracks, and crane tracks, providing the necessary support and stability for efficient and safe transportation of goods and passengers.

- Q: What are the different types of steel plates and their uses?

- There are several different types of steel plates, each with their own unique properties and uses. Some common types include carbon steel plates, which are versatile and used in a wide range of applications such as structural components and machinery parts. Stainless steel plates are corrosion-resistant and commonly used in food processing equipment, medical instruments, and construction projects. High-strength low-alloy (HSLA) steel plates are durable and used in heavy machinery and transportation equipment. Abrasion-resistant steel plates are designed to withstand wear and tear, making them suitable for applications like mining equipment and bulldozer blades. The specific type of steel plate chosen will depend on the desired characteristics and the intended use.

- Q: What are the different types of steel wire mesh products?

- There are several different types of steel wire mesh products available, including welded wire mesh, woven wire mesh, expanded metal mesh, and perforated metal mesh. Each type has its own unique characteristics and uses. Welded wire mesh is made by welding individual wires together at their intersections, creating a strong and durable mesh. Woven wire mesh is created by weaving wires together in a crisscross pattern, resulting in a flexible and versatile mesh. Expanded metal mesh is produced by cutting and stretching a metal sheet, creating diamond-shaped openings and providing excellent strength and rigidity. Perforated metal mesh is made by punching holes into a metal sheet, allowing for airflow, visibility, and various design options.

- Q: How are steel bars used in the reinforcement of bridges and flyovers?

- Steel bars are used in the reinforcement of bridges and flyovers to provide strength and stability to the structures. These bars are typically inserted into the concrete during construction to enhance the load-bearing capacity and prevent any potential cracking or failure. The steel bars, also known as rebar, act as a framework within the concrete, absorbing and distributing the loads and forces generated by the bridge or flyover, thus ensuring their structural integrity and durability.

Send your message to us

AISI316 Stainless Steel Shot Ball for Grinding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords