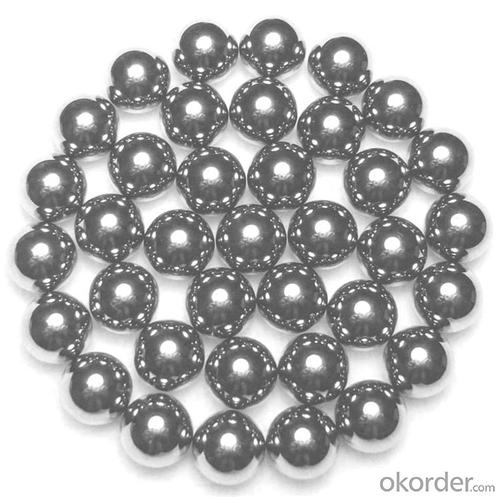

SUS304 Steel Shot Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

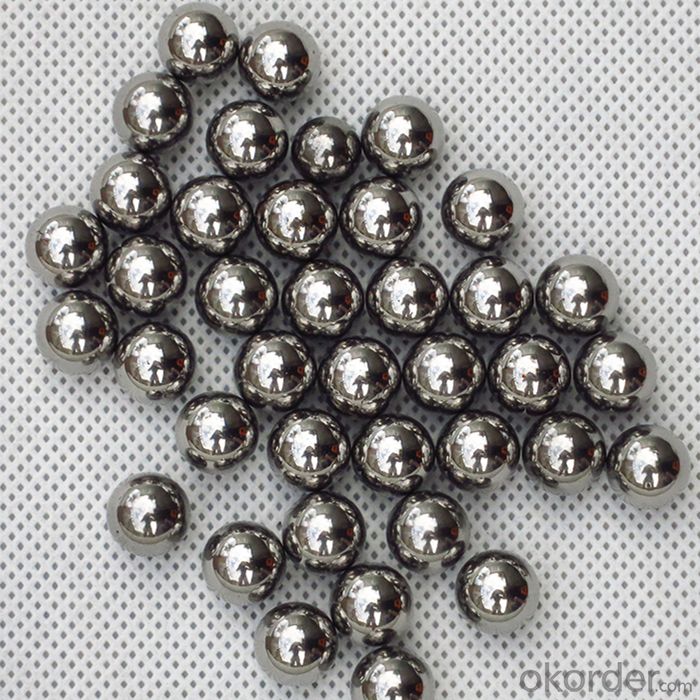

1, Chemical composition

304 Austenite Type (C)less than 0.25%, (Cr) 16-18%, (Ni) 6-10%, (Si)less than1%, (Mn)less than2%

430 Ferrite Type (C)less than0.25%, (Cr) 16-18%, (Si)less than1%, (Mn) less than1%

410 Martensite Type (C)less than 0.25%, (Cr)11-13%, (Si)less than1%, (Mn) less than 1%

2, Hardness1.0mm 51-53HRC 1.5mm 41-45HRC

Durability 6500 times

Microstructure:

304 Austenite Type Deformed Austenite

430 Ferrite Type Deformed Ferrite

410 Martensite Type Deformed Martensite

Density 7.8g/cm3

Bulk dendity 4.7g/cm3

Stainless steel shot production standards:

We strictly according to Japan JIS standard production stainless steel wire ingredients to production of sandblasting, peen-forming cleaning with stainless steel pill.

Application:

Stainless steel shot removing rust: Shot blasting rust-removal, shot peening rust-removal casting parts rust-removal, forged parts and steel plate rust-removal, H-beam steel rust-removal, steel structure rust-removal.

Stainless steel shot intensifying: Shot blasting intensifying of stainless steel parts and heat treatment parts.

Stainless steel shot shot peening: Shot peening of Coloured aluminum, copper, magnesium die-casting and stainless steel.

Application Devices:

Stainless steel shot is kind of abrasive used for shot blasting machine, shot blasting equipment, shot peening machine, shot peening equipment, sandblasting machine, sandblasting equipments, steel material pretreatment production line, steel plate pretreatment production line, steel structure pretreatment production line.

Packing Types:

Braided bag packing, flexible container packing, stock packing, paper bag packing, barrel packing.

- Q: What are the different types of steel bars and their uses?

- There are several different types of steel bars, each with their own unique properties and uses. Some common types include mild steel bars, which are versatile and commonly used in construction projects; deformed steel bars, which have ridges or deformations to improve grip and are often used in reinforced concrete structures; stainless steel bars, which are corrosion-resistant and commonly used in food processing, chemical plants, and construction; and alloy steel bars, which have various alloying elements added to enhance their strength and durability, making them suitable for applications in machinery, automotive, and aerospace industries.

- Q: How is steel used in the production of mining equipment?

- Steel is used in the production of mining equipment because of its strength, durability, and resistance to wear and tear. It is used to manufacture various components and structures in mining equipment such as drill bits, conveyor belts, crushing machines, and excavators, ensuring reliable and efficient operations in the mining industry.

- Q: What are the properties and characteristics of different steel products?

- Different steel products have varying properties and characteristics based on their composition, manufacturing process, and intended use. Some common properties include high strength, durability, and excellent corrosion resistance. Additionally, steel products can have different mechanical properties, such as hardness, ductility, and toughness, depending on their specific grade and heat treatment. These properties make steel products suitable for a wide range of applications, including construction, automotive manufacturing, and household appliances.

- Q: How does steel pipe coating for natural gas pipelines work?

- Steel pipe coating for natural gas pipelines works by applying a protective layer to the surface of the steel pipe to prevent corrosion and ensure the safe transport of natural gas. The coating materials used are usually epoxy or polyethylene, which are applied through various methods such as spraying or wrapping. This coating acts as a barrier against moisture, chemicals, and other external factors that can cause corrosion. It also provides insulation and enhances the durability of the pipeline, reducing the risk of leaks or damages.

- Q: How is steel used in the manufacturing of material handling equipment?

- Steel is commonly used in the manufacturing of material handling equipment due to its strength, durability, and versatility. It is used to create the frames, supports, and components of various equipment such as forklifts, cranes, conveyors, and storage racks. Steel's high tensile strength allows these equipment to handle heavy loads and withstand the rigors of daily use in industrial environments. Additionally, steel can be easily shaped, welded, and machined, making it an ideal choice for creating complex and customized designs required in material handling equipment.

- Q: How is steel used in the construction of sports facilities?

- Steel is commonly used in the construction of sports facilities due to its strength and durability. It is used to create the framework of the structures, such as the supports for roofs and walls. Steel is also used in the construction of bleachers, seating areas, and staircases. Its versatility allows for the creation of large, open spaces, ensuring the safety and comfort of spectators. Additionally, steel's resistance to corrosion makes it suitable for outdoor sports facilities, as it can withstand harsh weather conditions.

- Q: How is steel used in the energy sector?

- Steel is extensively used in the energy sector for various applications such as the construction of power plants, transmission towers, and pipelines. It is also used in the production of wind turbines, solar panels, and nuclear reactors. The durability, strength, and heat resistance of steel make it an ideal material for supporting and safeguarding critical energy infrastructure.

- Q: What are the different types of steel fasteners and connectors available?

- There are several types of steel fasteners and connectors available, including screws, bolts, nuts, washers, rivets, and nails. Each type serves a specific purpose and is designed to provide a secure and reliable connection in various applications.

- Q: How is steel wire rope inspected for safety?

- Steel wire rope is inspected for safety through a comprehensive process that includes visual examination, non-destructive testing techniques, and load testing. Trained inspectors carefully examine the rope for any visible signs of wear, corrosion, or damage. Non-destructive testing methods such as magnetic particle inspection or ultrasonic testing are used to detect any internal flaws or defects that may not be visible. Additionally, load testing is conducted to determine the rope's ability to withstand its specified working load. Through these rigorous inspections, the safety of steel wire rope is ensured, reducing the risk of failure and promoting safe operations.

- Q: How is steel coil produced?

- Steel coil is produced through a process called hot rolling, where a slab of heated steel is passed through a series of rollers to reduce its thickness and shape it into a long, coiled strip. This strip is then cooled and processed further to achieve the desired quality and specifications before being cut into individual coils for various industrial applications.

Send your message to us

SUS304 Steel Shot Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords