2mm-15mm SUS304 Steel Shot Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

304

Certification:

ISO

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

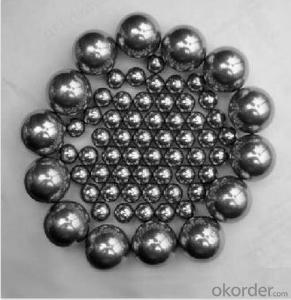

2mm-15mm SUS304 Steel Shot Stainless Steel Ball

The detail of 2mm-15mm SUS304 Steel Shot Stainless Steel Ball

Hereare many kinds of stainless steel balls, AISI 304, AISI 316, AISI 316L, AISI 420, AISI 420C,

AISI 440, AISI 440C.AISI 304 steel ballshave no good hardness but offer good corrosion resistance,

they offer good resistance to atomospheric corrosion, dyes, food processing, valves, sex products and so on.

AISI 304 stainless steel ball in our factory :

Minimum diameter: 2mm

Best precision :G100

Hardness :HRc25-39

| Product | 2mm-15mm SUS304 Steel Shot Stainless Steel Ball |

| Material | stainless steel |

| Brand | SAIGE |

| Percision | G100 |

| Hardness | HRC25-39 |

| Surface | zerodefect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

AISI 304 chemical Composition

| Materials Standard | Chemical Composition (%) | Hardness | ||||||

| JIS SUS304 (AISI304) (Din X5CrNi18-10) | C | Cr | Ni | Si | Mn | P | S | HRC25-39 |

| <0.08 | 18.00-20.00 | 8.00-10.50 | <1.0 | <2.0 | <0.045 | <0.030 | ||

The adventage of 2mm-15mm SUS304 Steel Shot Stainless Steel Ball

A, Safe Package

Step 1: Weighing stainless steel balls. Usually the weight is about 10kg.

Step 2: Sealed plastic bags

Step 3: Put sealed plastic bags into small boxes.

Step 4: Each box has the label, including material, Lot No. Size, quantity, grade, date and so on

Step 5: Each box directly put into mooden case.

High precision stainless steel balls usually is oil package. Normal precision stainless steel balls usually is dry package.

We also can pack them according to customers' request.

B,Sample free

If you are interested in our product , we can send you our free sample for you . Please contact us as soon as possible.

- Q: How does steel pipe threading work?

- Steel pipe threading is a process where a steel pipe is cut with a specialized tool to create external threads, which allows for the connection of fittings and other pipes. The threading tool, typically a die, is applied to the pipe, and as it is rotated, it gradually cuts grooves into the pipe's surface, forming the threads. This threading process ensures a secure and leak-free connection when joining pipes together.

- Q: How does steel sheet metal bending and forming work?

- Steel sheet metal bending and forming involve applying force to a sheet of steel to shape it into a desired form, such as a bend, curve, or complex shape. This process is typically done using specialized machines called press brakes, which have a V-shaped die and a punch. The sheet metal is placed between the die and punch, and force is applied to the punch, causing the metal to deform and take the shape of the die. The amount of force, angle of the die, and other variables determine the final shape and accuracy of the bending process.

- Q: How does steel sheet metal fabrication work?

- Steel sheet metal fabrication is the process of transforming flat steel sheets into various shapes and structures through cutting, forming, and assembling. It typically involves steps such as cutting the sheet into the desired size, shaping it through bending or rolling, joining multiple pieces through welding or fastening, and adding finishing touches like painting or coating. This precise and intricate process allows for the creation of a wide range of products, from simple brackets to complex machinery components, by utilizing the versatility and strength of steel.

- Q: How does the thickness of steel affect its strength?

- The thickness of steel directly affects its strength, as thicker steel tends to have greater strength. This is because the thickness of the steel provides resistance to external forces and reduces deformation under stress. Thicker steel can withstand higher loads and is less prone to bending or breaking, making it more durable and stronger in various applications.

- Q: What are the different types of steel springs and their applications?

- There are several types of steel springs commonly used in various applications. Compression springs are used to resist compressive forces and are found in automotive suspensions, mattresses, and mechanical devices. Extension springs are designed to resist stretching forces and are commonly used in garage doors, trampolines, and industrial equipment. Torsion springs provide rotational force and are found in door hinges, clothespins, and various mechanical assemblies. Additionally, flat springs are used for applications that require flexibility, such as automotive clutches and electrical switches. These different types of springs offer varying degrees of strength, durability, and flexibility, allowing them to be utilized in a wide range of industries.

- Q: What are the main properties of steel?

- The main properties of steel include high strength, durability, versatility, and excellent thermal and electrical conductivity. Additionally, steel is known for its corrosion resistance, ease of fabrication, and recyclability.

- Q: How is steel used in the manufacturing of elevators and escalators?

- Steel is used in the manufacturing of elevators and escalators for its superior strength, durability, and ability to withstand heavy loads. It is used to construct the main structural components, such as the framework, support beams, and carriages, providing stability and ensuring safe transportation. Additionally, steel is used for various other parts, including doors, panels, and handrails, as it can be easily fabricated and customized to meet specific design requirements.

- Q: How are steel products used in the construction of high-rise buildings?

- Steel products are used extensively in the construction of high-rise buildings due to their strength, durability, and versatility. They are commonly used for structural elements such as beams, columns, and frames, providing the necessary support and stability to withstand the weight and forces experienced by tall buildings. Additionally, steel is also used for cladding, roofing, and other architectural features, offering aesthetic appeal and functionality. Overall, steel's superior properties make it an ideal material for constructing safe and efficient high-rise buildings.

- Q: What are the different types of steel roofing systems?

- There are several types of steel roofing systems, including standing seam, corrugated, and metal shingle roofs.

- Q: What are the different types of steel meshes and their applications?

- There are several types of steel meshes, each with its own unique characteristics and applications. 1. Welded Wire Mesh: This type of mesh consists of welded intersections, creating a rigid and strong structure. It is commonly used in construction projects for concrete reinforcement, fencing, and animal enclosures. 2. Expanded Metal Mesh: Made by cutting and stretching a metal sheet, this mesh has a diamond-shaped pattern. It is used in architectural applications, such as building facades, walkways, and filtration systems. 3. Woven Wire Mesh: Constructed through interlacing wires, this type of mesh is available in various patterns and sizes. It finds applications in industries like agriculture, mining, and filtration, where it is used for screening, sieving, and separating materials. 4. Perforated Metal Mesh: It is created by punching holes into a metal sheet, resulting in a pattern of regularly spaced openings. This mesh is widely used in industries like HVAC, automotive, and architecture for air ventilation, acoustic panels, and decorative purposes. 5. Wire Cloth: Composed of woven wires, wire cloth is used for a wide range of applications, including filtration, insect screening, and sieving. It is commonly found in industries such as food processing, chemical processing, and mining. These are just a few examples of steel meshes, and their applications are vast and diverse. The choice of mesh type depends on the specific requirements of the application, including strength, durability, aesthetics, and functionality.

Send your message to us

2mm-15mm SUS304 Steel Shot Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords