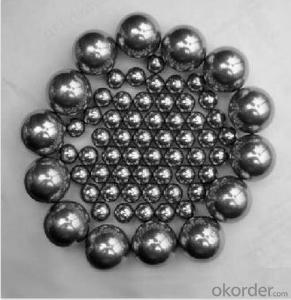

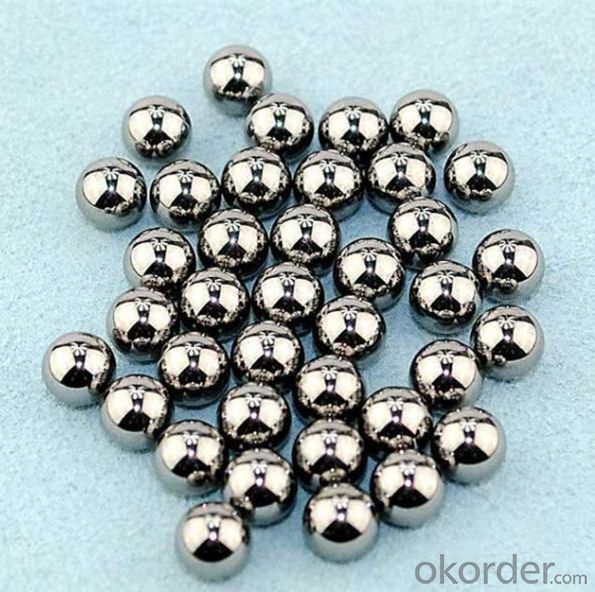

SUS304 Steel Shot 2mm-15mm Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

The detail of AISI304 stianless steel ball

Hereare many kinds of stainless steel balls, AISI 304, AISI 316, AISI 316L, AISI 420, AISI 420C,

AISI 440, AISI 440C.AISI 304 steel ballshave no good hardness but offer good corrosion resistance,

they offer good resistance to atomospheric corrosion, dyes, food processing, valves, sex products and so on.

AISI 304 stainless steel ball in our factory :

Minimum diameter: 2mm

Best precision :G100

Hardness :HRc25-39

| Product | SUS304 Steel Shot 2mm-15mm Chemical Product Stainless Steel Ball |

| Material | stainless steel |

| Brand | SAIGE |

| Percision | G100 |

| Hardness | HRC25-39 |

| Surface | zerodefect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

AISI 304 chemical Composition

| Materials Standard | Chemical Composition (%) | Hardness | ||||||

| JIS SUS304 (AISI304) (Din X5CrNi18-10) | C | Cr | Ni | Si | Mn | P | S | HRC25-39 |

| <0.08< td=""> | 18.00-20.00 | 8.00-10.50 | <1.0< td=""> | <2.0< td=""> | <0.045< td=""> | <0.030< td=""> | ||

PACKAGING

Type 1 : Plastic bag + box + carton + wooden pallet

Type 2 : Plastic bag + carton + wooden pallet

Type 3 : Our package :export cartons, steel drums, wooden pallets

- Q: What are the applications of steel in the food processing industry?

- Steel is widely used in the food processing industry due to its various beneficial properties. It is commonly employed in the construction of machinery, equipment, and storage containers. Stainless steel, in particular, is highly resistant to corrosion, making it ideal for food contact surfaces and ensuring the safety and hygiene of food products. Additionally, steel's durability and strength make it suitable for heavy-duty applications such as food processing machinery, conveyors, and cutting tools. Overall, steel plays a crucial role in maintaining food quality, safety, and efficiency in the food processing industry.

- Q: How does steel sheet metal fabrication work?

- Steel sheet metal fabrication is a process that involves cutting, bending, and shaping steel sheets to create various products. It begins with the design phase, where engineers create a blueprint or CAD model of the desired product. Next, the steel sheets are cut using different techniques such as laser cutting or shearing. The cut sheets are then bent into shape using press brakes or other methods, and additional processes like welding or stamping may be used to join or add details to the metal. Finally, the fabricated steel sheet is finished by sanding, painting, or coating to enhance its appearance and protect it from corrosion.

- Q: How is steel wire galvanized?

- Steel wire is galvanized through a process called hot-dip galvanizing. In this method, the steel wire is first cleaned to remove any impurities and then dipped into a bath of molten zinc. The zinc coating bonds with the steel wire, creating a protective layer that helps prevent corrosion and rust. The wire is then cooled and ready for various applications.

- Q: What are the different types of steel springs and their uses?

- There are several types of steel springs, each designed for specific applications. Some common types include compression springs, which are used to resist compressive forces and store energy; extension springs, which resist stretching and are commonly found in trampolines or garage doors; torsion springs, which generate rotational force and are used in clothespins or mousetraps; and flat springs, which provide flexibility in limited spaces, such as in automotive suspensions. Each type of spring has a unique design and purpose, allowing them to be utilized in a wide range of industries and products.

- Q: How is steel used in the production of consumer goods?

- Steel is used in the production of consumer goods in various ways, such as in the manufacturing of appliances, automobiles, furniture, tools, and packaging materials. It is valued for its strength, durability, and versatility, making it an essential material for constructing and designing a wide range of products that are used by consumers on a daily basis.

- Q: What are the different types of steel reinforcement used in construction?

- There are various types of steel reinforcement used in construction, including mild steel bars, deformed steel bars, welded wire mesh, and steel fibers.

- Q: What are the properties of high-strength low-alloy (HSLA) steel?

- High-strength low-alloy (HSLA) steel possesses a combination of excellent mechanical properties, including high tensile strength, improved toughness, and enhanced corrosion resistance. It is known for its ability to withstand high levels of stress without compromising its structural integrity. Additionally, HSLA steel offers cost-effectiveness due to its reduced alloying elements, making it a popular choice in various industries such as automotive, construction, and manufacturing.

- Q: How are steel forgings used in the aerospace industry?

- Steel forgings are widely used in the aerospace industry due to their exceptional strength, durability, and resistance to extreme conditions. These forgings are utilized in critical aerospace components such as landing gear, turbine discs, engine mounts, and structural parts. With their ability to withstand high temperatures and pressures, steel forgings ensure the reliability and safety of aircraft, enabling them to perform optimally in demanding environments.

- Q: How is steel plate heat-treated for optimal strength?

- Steel plate is heat-treated for optimal strength through a process called quenching and tempering. In this process, the plate is heated to a high temperature, typically above its critical temperature, and then rapidly cooled, or quenched, in water or oil. This rapid cooling helps to harden the steel, making it stronger but also more brittle. To improve its toughness and ductility, the quenched steel is then reheated, or tempered, at a lower temperature. This tempering process helps to relieve internal stresses and allows the steel to regain some of its flexibility and resistance to cracking, resulting in a steel plate with optimal strength.

- Q: What are the different types of steel tanks and their applications?

- There are various types of steel tanks used for different applications. Some common types include above ground storage tanks (ASTs) used for storing liquids such as petroleum, chemicals, or water; underground storage tanks (USTs) typically used for storing hazardous materials or petroleum products; and pressure vessels used in industrial processes for containing gases or liquids under high pressure. Additionally, steel tanks can be categorized based on their design, such as cylindrical, rectangular, or spherical tanks. The specific application of steel tanks depends on factors like the type of material being stored, the required volume or capacity, and the environmental conditions in which they will be used.

Send your message to us

SUS304 Steel Shot 2mm-15mm Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords