Manufacturer of Glue Steel Fiber

- Loading Port:

- Guangzhou Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 50000000 Ton Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

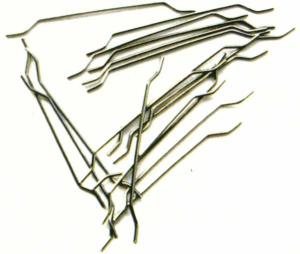

Introduction of Glue Steel Fiber:

The Glue Steel Fiber uses high-quality low-carbon steel wire, they are high-performance steel fiber, with the characteristics of the high tensile strength, good toughness, etc. The product is widely welcomed by our clients all over the world. The professional service and good quality has won high reputation all over the world. The Glue Steel Fiber could avoid the fiber tangle get together, it is more smooth when mixed.

Data Sheet of Glue Steel Fiber:

DIA (mm) | Length (mm) | Tensile Strength (MP) |

1 | 60 | ≥1000 |

1 | 50 | ≥1000 |

0.9 | 60 | ≥1000 |

0.9 | 50 | ≥1000 |

0.75 | 60 | ≥1000 |

0.75 | 45 | ≥1000 |

0.75 | 35 | ≥1000 |

0.55 | 30 | ≥1000 |

0.5 | 30 | ≥1000 |

0.5 | 25 | ≥1000 |

0.4 | 25 | ≥1000 |

Application of glue steel fiber:

Primary dispersion: Direct adding steel fibers to the belt, the rows of steel fiber as a whole, each of the concrete uniformly dispersed

Corner

Secondary dispersion: a water-soluble glue starts to dissolve, in a row of steel fibers in a dispersion premise, dispersed again in every corner of the monofilament fiber, showing a perspective view in the concrete of the fiber web, which play the role of an overall reinforcement .

- Q: How is steel used in the production of tools and hardware?

- Steel is widely used in the production of tools and hardware due to its exceptional strength, durability, and versatility. It is used to create various cutting tools, such as saw blades, drills, and chisels, allowing for precise and efficient cutting. Steel also forms the basis for many hand tools like wrenches, hammers, and screwdrivers, providing the necessary strength to withstand heavy use. Additionally, steel is used in the production of hardware items like hinges, locks, and fasteners, as it offers excellent resistance to corrosion and wear. Overall, steel's properties make it an essential material in the manufacturing of tools and hardware for a wide range of applications.

- Q: How is steel used in the production of laboratory furniture?

- Steel is commonly used in the production of laboratory furniture due to its durability, strength, and resistance to corrosion. It is used for constructing lab benches, cabinets, and shelves, providing a sturdy and stable surface for experiments and equipment. Steel also allows for easy cleaning and maintenance, making it suitable for a sterile laboratory environment.

- Q: How do steel products contribute to the education and institutional sector?

- Steel products contribute to the education and institutional sector in various ways. Firstly, steel is used in the construction of educational buildings, such as schools and universities, providing sturdy and durable structures that can withstand the test of time. Additionally, steel is used in the manufacturing of furniture, equipment, and fixtures within these institutions, ensuring functionality, safety, and aesthetic appeal. Moreover, steel is also utilized in the production of transportation vehicles, such as buses and trains, which facilitate the transportation of students and staff to and from educational institutions. Overall, steel products play a crucial role in creating conducive learning environments and supporting the infrastructure needs of the education and institutional sector.

- Q: How is steel used in the production of medical devices?

- Steel is used in the production of medical devices due to its strength, durability, and resistance to corrosion. It is commonly used for manufacturing surgical instruments, implants, and various medical equipment such as scalpel blades, forceps, needles, and stents. The properties of steel make it ideal for these applications as it provides reliability, precision, and ease of sterilization, ensuring the safety and effectiveness of medical devices used in patient care.

- Q: How is steel used in the production of electrical transformers?

- Steel is used in the production of electrical transformers to provide structural support and magnetic properties necessary for efficient power transmission. It forms the core of the transformer, allowing the magnetic field to be created and transferred to the secondary winding, enabling the transformation of electrical energy.

- Q: How are steel products used in the construction of libraries and educational centers?

- Steel products are commonly used in the construction of libraries and educational centers for various purposes. Steel beams and columns are used to provide structural support, ensuring the durability and stability of the building. Steel frames are also used for walls and roofs, allowing for flexible and efficient design options. Additionally, steel is used for doors, windows, and other architectural elements, providing security and aesthetic appeal. Overall, steel products play a crucial role in constructing safe, functional, and aesthetically pleasing libraries and educational centers.

- Q: How is steel used in the production of packaging materials?

- Steel is commonly used in the production of packaging materials due to its strength, durability, and ability to withstand external pressures. Steel is often used to create cans, drums, and other containers that are used for storing and transporting various products. Its resistance to corrosion and impact makes it an ideal choice for packaging materials, ensuring the protection and preservation of goods throughout the supply chain.

- Q: How is steel used in the manufacturing of transportation equipment?

- Steel is commonly used in the manufacturing of transportation equipment due to its strength, durability, and ability to withstand high levels of stress. It is utilized in various components such as frames, bodies, engine parts, and suspension systems, contributing to the overall structural integrity and safety of vehicles, ships, trains, and airplanes.

- Q: What are the advantages of using steel in the manufacturing of playground equipment?

- There are several advantages of using steel in the manufacturing of playground equipment. Firstly, steel is a highly durable material that can withstand heavy use and harsh weather conditions, making it ideal for outdoor play areas. Secondly, steel is resistant to corrosion, which ensures the longevity of the playground equipment and reduces maintenance costs. Additionally, steel is a versatile material that can be easily molded into various shapes and designs, allowing for the creation of innovative and engaging play structures. Lastly, steel is a safe option as it has high strength-to-weight ratio, providing stability and support for children while they play.

- Q: How is steel used in the construction of amusement parks and entertainment venues?

- Steel is commonly used in the construction of amusement parks and entertainment venues due to its strength, durability, and versatility. It is used to build roller coasters, ferris wheels, ride structures, and various other attractions. Steel provides the necessary support to ensure the safety and stability of these structures, allowing for thrilling and enjoyable experiences for visitors.

1. Manufacturer Overview

| Location | Hunan, China |

| Year Established | 1989 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Guangzhou Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Manufacturer of Glue Steel Fiber

- Loading Port:

- Guangzhou Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 50000000 Ton Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords