Stainless Steel Ball

Stainless Steel Ball Related Searches

Stainless Steel Balls Stainless Steel Ball Chain Stainless Steel Gazing Ball Stainless Steel Ball Stretcher Stainless Steel Basket Stainless Steel Block Stainless Steel Wall Stainless Steel Gun Stainless Steel Barbell Stainless Steel Pistol Stainless Steel Baseboard Stainless Steel Bong Stainless Steel Hoops Stainless Steel Door Stainless Steel Bar Stool Stainless Steel Roller Stainless Steel Blade Stainless Steel Belt Stainless Steel Weld Stainless Steel Pool Stainless Steel Waste Basket Stainless Steel Stool Stainless Steel Hardware Stainless Steel Base Stainless Steel Shot Stainless Steel Glass Stainless Steel Wire Basket Stainless Steel Gate Stainless Steel Drill Stainless Steel ShotgunStainless Steel Ball Supplier & Manufacturer from China

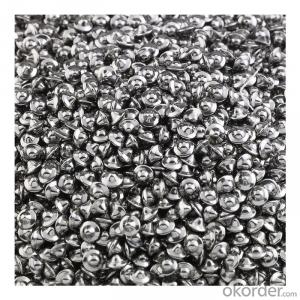

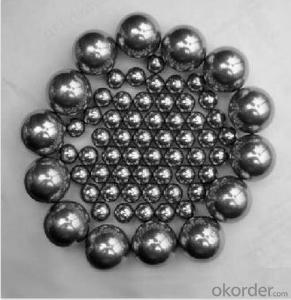

Stainless steel balls are precision balls made from stainless steel material, known for their excellent corrosion resistance, wear resistance, and dimensional accuracy. These balls are widely used in various industries such as aerospace, automotive, food processing, and medical equipment due to their high performance and durability. In many applications, stainless steel balls are utilized as bearing components, fasteners, or in precision instruments where reliability and longevity are crucial. Okorder.com is a reputable wholesale supplier of stainless steel balls, offering a vast inventory to cater to the diverse needs of customers across different sectors. By providing high-quality stainless steel balls at competitive prices, Okorder.com ensures that clients receive the best value for their investments.Hot Products