float ball valve ; ball valve ; CLASS150--2500 ball valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Normal pressure or rating | Class 150-Class 2500,JIS I0K - 20K,PN 10 - PN 420 | |||

Normal diameter or bore | NPS 1/2-40,DN6-1000 | |||

Applicable temperature | -196℃-540℃ | |||

Operation type | Manual,worm gear,pneumatic,electric | |||

Standards and specification

| Design& manufacture

| API6D.API608.ASMEBI6.34,ISO5211,ANSI/AWWAC507,BFCI70-2.MSSSP-72,BS5351,B56364,NACE MR0175

| Connection ends

| ASMEBI6.5,ASMEB16.47.API 605,MSS SP-44,ISO 7005-1,JISB2238,BS12627,ASMEBI6.25,ASMEB16.11,BS 12760 |

Face to face dimension | ASMEB16.10,ISO 5752,BS 558, BS12982

| Testing &inspection | API598,API6D,API607,API6FA,BS6755.BS12569,MSS SP-82,MSS SP-6I | |

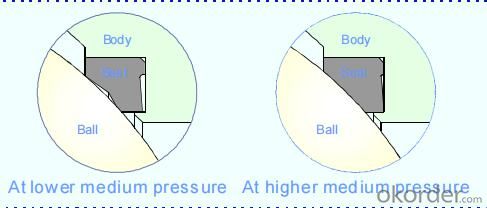

Reliable seat seal

The structure design of elastic sealing ring has been adopted for floating ball valves. This seat design features a bigger sealing pressure ratio between the ring surface and the ball when medium pressure gets lower, where the contacting area is smaller. Thus, the reliable seal is ensured. When the medium pressure gets higher, the contacting area between seat ring and ball becomes bigger as the sealing ring transforms elastically to undertake the bigger force 5 pushed by the medium without any damage.

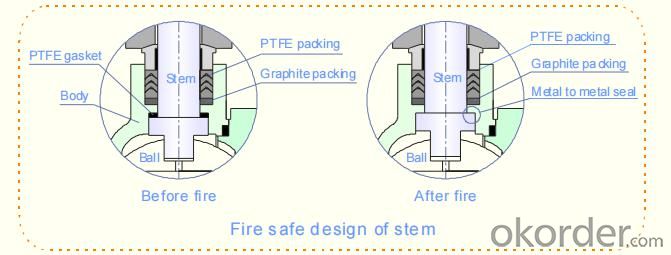

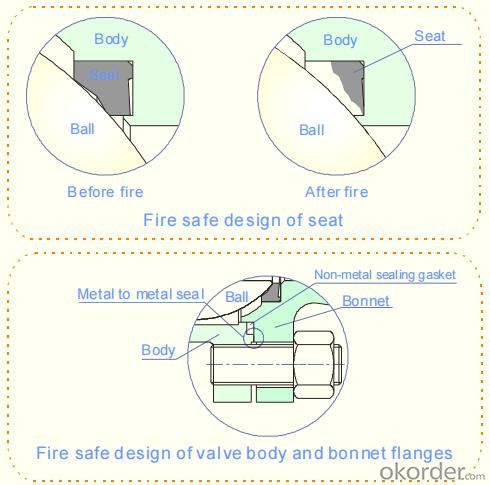

Fire safe design

With the valve heated in a fire application, the non-metal material parts such as seat sealing ring of PTFE, stem back seat gasket, gland packing, and the sealing gasket between body and bonnet might disintegrate or be damaged due to high temperature. Specially designed structure of auxiliary metal to metal seal is provided to effectively prevent both internal and external leakage of the valve. As required by customers, floating ball valves with fire safe design can meet the requirement of API 607, API 6FA, BS6755 and B/T 6899

Reliable stem seal

The blow-out proof design has been adopted for the stem to ensure that even if the pressure in the body cavity is risen accidently and the packing flange becomes invalid, the stem may not be blown out by medium. The stem features the design with a backseat, being assembled from underneath. The sealing force against the backseat gets higher as the medium pressure becomes higher. So the reliable seal of the stem can be assured under variable medium pressure

Anti-static feature

The traditional packing flange design has been improved to be of two piece structure, i.e., being as a packing flange plate and a follower, the latter contacts the flange plate with spherical surface. Thus, the follower remains vertical always, and is lined internally with a PTFE bush to prevent the galling against and friction between the stem, which can also reduce the operation torque of the valve.

The traditional packing flange design has been improved to be of two piece structure, i.e., being as a gland flange and gland, the latter contacts the gland flange with spherical surface. Thus, the gland remains vertical always, and is lined internally with a PTFE bush to prevent the galling against and friction between the stem, which can also reduce the operation torque of the valve.

- Q: Hard sealing ball valve, what method can calculate the leakage? How much is grade 4? How much is grade 5? How much is level 6? For example: how many DN150 seals are 5 ml?

- Valve leakage level is actually the valve sealing class. There are two kinds of GB and American Standard.

- Q: What does telescopic ball valve mean? What does it mean?

- In fact, the length of L can vary within a certain range

- Q: Gate valve, ball valve, the difference between the pressure regulating valve

- Gate valve and stop valve are shut-off valve, is the most common two valves. From the exterior, the gate valve is shorter than the cut-off valve, especially the bar valve needs a higher height space. Valve sealing surface has a certain degree of self sealing capacity, its spool depends on the media pressure tight contact with the valve seat sealing surface, to achieve tight leakage. Wedge gate valve spool angle is generally 3~6 degrees, when forced to shut down excessive or temperature changes of the valve core is easy to die. Therefore, high temperature and high pressure wedge gate valve, in the structure have taken certain measures to prevent spool stuck. The valve in the opening and closing valve and valve seat sealing surface contact and mutual friction is always so easy to wear sealing surface, especially in close off the valve, the valve before and after the great pressure, sealing surface wear is more serious. Compared with the cut-off valve, the main advantage is that the flow resistance is small, the flow resistance coefficient of ordinary gate valve is about 0.08~0.12, while the ordinary cut-off valve resistance coefficient is about 3.5~4.5. Opening, closing force is small, the medium can flow in two directions.

- Q: Which is the smallest flow valve, globe valve or butterfly valve? Which one is the biggest?

- Full diameter ball valve flow resistance is minimal, the flow resistance of the globe valve is large

- Q: O ball as general regulation of opening extent

- Hard seal can be adjusted, soft sealed, please be careful.The opening 0~90 curve is getting faster and faster

- Q: The toilet water pipe valve is broken, with a new twist, how are the screw does not move, then they told me to go on to the pipe on the water and then tighten, did as he said, really screwed, but do not know why, please tell the master what is the principle, if it is water without water when the screw does not move, but when the water can twist. What a kink!Is the water valve normal, a pull rod, pulling it back flush, do not rush the kind, the middle is a hollow ball

- I think it should be the water holding gas, connecting device principle, at the bottom of the hand, barometric pressure, and the best you can last map, I'll see

- Q: What are the structural shapes of the eccentric hemisphere valve, what are their respective characteristics?

- The eccentric hemisphere valve and the flange gate valve belong to the same type of valve. The difference is that the closing piece is a sphere, and the ball rotates around the center of the valve body to open and close a valve. Ball valve in the pipeline is mainly used to do cutting, distribution and change the direction of flow medium. Two piece ball valve, three piece ball valve, is widely used in recent years, a new type of valve.

- Q: The two valves are available for the flow of the electromagnetic valve switch, I contact more, found for water solenoid valve are caged water, to repair several times because of impurities or newly installed pipeline with raw materials flowing through the valve, close the valve body when not to rely on Yan, a seepage water tank to diffuse phenomenon!I am looking for a replacement, I think the electric valve should be a good choice, not used to a conclusion.Please use the electric ball valve to talk about friends, or for the two kinds of friends who have an understanding to talk aboutOr there is no better substituteThere seems to control the solenoid valve and electric valve is not the same, the solenoid valve is normally open and closed to control the electric valve is controlled by the trigger (like), if used to replace it, what is the controller?

- Solenoid valve on the medium cleanliness requirements are very high, when the water is not clean, easy to leak. You use the solenoid valve is leaking, that's the case.If you have an air source, use pneumatic angle seat valvesIf only the power supply, the electric ball valve.Electromagnetic valve is electromagnetic rail, electric suction from the electromagnetic core, so that the valve openThe electric ball valve is driven by the motor to drive the valve open. If only switch, then do not need to install any controller, when buying, must explain is the switch ball valve.This answer was net friend adoption

- Q: What does "ball valve" Q41F-10P mean?

- Q valve (Qiu represents the first letter of the alphabet), 4 representative flange, second representative is 1 ball valve floating ball (ball valve floating ball and fixed ball, 7 ball, F fixed on behalf of) on behalf of PTFE- PTFE seal (PTFE PTFE), representing 10 of the nominal pressure valve is 10 kg (1.0Mpa), P represents the valve body material is 304 stainless steel.Soft sealing stainless steel flanged ball valve

- Q: Ball valve, PTFE pad inappropriate choice, is not easy to bad ah?

- 120 - 150. TemperatureChasing the answerYes, but not in a high temperature for a long time, like more than 180 degrees centigrade. Because the gasket can not be used after deformation, it will cause valve leakage.

Send your message to us

float ball valve ; ball valve ; CLASS150--2500 ball valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords