High Quality Forged Steel Full Bore High Pressure Ball Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Forged Steel Full Bore High Pressure Ball Valve

Design Features Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Blow-out proof stem

Key lock

Anti-fire safe design

Anti-static device

Free leakage of body Sealed construction

Double block&bleed (DBB)

Emergency sealing

Automatic body cavity relief

Various driving types

Fire safe design to API 607/ API 6FA

Anti-static to BS 5351

Cavity pressure self relief

Optional locking device

Specifications of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Size: 1/4"-2"

Pressure: Class150LB-900LB

Material: WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L,ASTM A351

Design & Manufacture Std.: API608, ASME B16.34

Connection Ends: Threaded (Female/Female), NPT, BSP, BSPT, DIN259/2999, Butt welded, Socket welded (BW, SW)

Test Standard: API598

Structure Type: One-piece, Two-piece, Three-piece, Reduced Bore

Operated way: Lever

Suitable medium: Water, oil, steam, nitric acid, acetate acid and so on

Suitable temperature: -40 deg+150deg be able to endure high pressure

Seat: PTFE. Material and good on-off feature.

Working pressure: 1000psi

Thread standard: International BSPT, NPT, DIN, surface is flat, allow overrun

|

Nominal pressure |

PN(mpa) |

2.5 |

4 |

6.4 |

|

|

Shell Test Pressure |

PS(mpa) |

3.75 |

6 |

9.6 |

|

|

Sealing test pressure |

2.75 |

4.4 |

7.04 |

| |

|

TightnessTest Pressure |

0.6 |

0.6 |

0.6 |

| |

|

For media |

SS201 |

SS304 |

SS316 |

| |

|

Water, oil and gas medium |

Nitric acid corrosive media |

Acetic acid corrosive medium |

| ||

|

For temperature |

-40°C——+150°C |

||||

|

Product Standards |

GB/T12237-2007 |

| |||

|

Test |

GB/T13927-1992 JB/T9092-1999 |

||||

Applicable Standard Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Design Standard: API 6D, ASME B16.34, API 608, BS 5351, MSS SP-72

Face to Face: API 6D, ASME B16.10, EN 558

End Connection: ASME B16.5, ASME B16.25

Inspection and Test: API 6D, API 598

Design Description Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Double block and bleed design(DBB)

Double stem sealing. The ball can maintain pressure sealing of pipeline when it is closed or fully opened.

Shorter upper sleeve reduces bearing load and operation torue

Limit device ensures the accurate opening and closing position of the valve

The vall and stem are separated so as to reduce stem load. The stem adopts anti-blow-out design.

The sealing surface is inserted into te metal seat by polymer or plastic

The metalbacked self-lubricating PTFE bearing and PTFE thrust washers

Reduce the opening torque and prolong the service life of the valve. Stem leakage can be prevented through the emergency grease fitting.

Nickel and phosphor treatment to the parts can enhance the anticorrosive performance.

The fireproof design of metal wound gasket compassed of stainless steel and graphite can prevent external leakage.

Usage/Applications Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

It can be widely used in Metallurgy, Mine, Petrochemical, Chemical, Oil & Gas transmission pipeline, Power plant, Heating power and Pharmacy, etc.

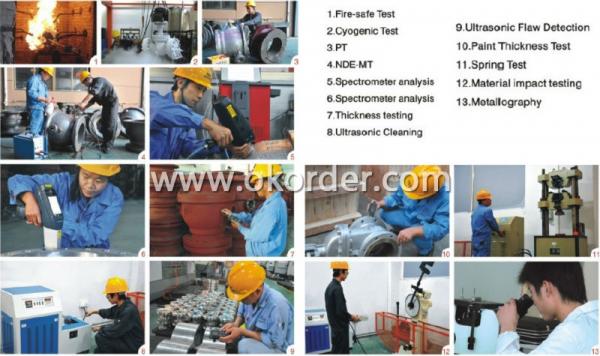

Main Test Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Packaging & Delivery Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Packaging: Inner packing: Plastic bags, Outer packing: Cartons and wooden case.

- Q: The working principle of the track type ball valve

- Baidu under the Wuxi East valve, have their contact information, you can consult them

- Q: What does W represent in copper ball valve Q11W-16T?

- Valve sealing materials are all valves of the body material, sealing surface material code with "W" said

- Q: Gate valve, ball valve, the difference between the pressure regulating valve

- To this end, the media from below to enter the way, generally only applicable to small caliber manual stop valve, to the valve closed, the media acting on the spool of force is not greater than 350kg limit. Electric cut-off valve is generally used to enter the media from the top way. The disadvantage of the medium entering from the top is just the opposite of the way it is entered below. Compared with the gate valve, the utility model has the advantages of simple structure, good sealing performance, and convenient manufacture and maintenance. The disadvantage is that the liquid resistance is large, and the opening and closing force is large. Gate and globe valves are fully open closed type valve, cut off or connected as the medium use, not as a control valve. The range of application of stop valves and gate valves is determined by their characteristics. In the smaller passages, the cut-off valve is used when required for better shutoff; in the steam pipe and the large diameter water supply pipe, the gate valve is generally used because of less fluid resistance.

- Q: What's the difference between air valves, butterfly valves and ball valves?

- 1. air valve is an important component of the compressor cylinder, which is responsible for the inhalation and discharge of gas. The traditional air valve is composed of valve seat, valve plate, spring, lift limiter, bolt and so on.2 also known as butterfly valve, control valve has a simple structure, can be used for the work of low pressure pipeline medium valve butterfly valve switch control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve in the pipe is cut. Off and throttling effect.3. ball valve: opening and closing parts (sphere) driven by the stem, and around the square ball valve for the axis of the rotating valve.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q: Valve and ball valve is the same thing? Don't know don't speak

- Ball valves belong to a large class of valves, valves include gate valve, butterfly valve, check valve, globe valve, ball valve, trap valve, safety valve, etc. all valves

- Q: What are the structural shapes of the eccentric hemisphere valve, what are their respective characteristics?

- The eccentric hemisphere valve and the flange gate valve belong to the same type of valve. The difference is that the closing piece is a sphere, and the ball rotates around the center of the valve body to open and close a valve. Ball valve in the pipeline is mainly used to do cutting, distribution and change the direction of flow medium. Two piece ball valve, three piece ball valve, is widely used in recent years, a new type of valve.

- Q: What's the difference between a medium-sized ball valve and a heavy ball valve?

- It's almost certain that you made an inquiry at the small valve manufacturer in Wenzhou.In fact, the main wall thickness is differentThe so-called heavy, is in accordance with the GB/T12237 Petrochemical ball valve wall thickness to designThe so-called medium-sized, is in accordance with the GB/T12224 steel ball valve wall thickness to design, two wall thickness of some difference, plus a little steal material, sphere do hands and feet, the price can be much lower.There is a light, that is the material does not meet the standards, basically sold to plumbing builders.

- Q: What is an eccentric hemispherical valve? How do you understand?

- The eccentric hemisphere valve and the flange gate valve belong to the same type of valve. The difference is that the closing piece is a sphere, and the ball rotates around the center of the valve body to open and close a valve.

- Q: What is the difference between ball valve and plug valve?

- Plug valves are closed or plunger shaped rotary valve, through the rotation of 90 degrees to make the valve plug on the mouth of the channel with the valve on the mouth of the same or separated, to achieve a valve opening or closing. Plug valve plug shape can be cylindrical or conical. In the cylindrical valve plug, the channel is generally rectangular; in the tapered valve plug, the channel is trapezoidal. These shapes make the structure of the plug valve lighter, but at the same time a certain loss. Plug valves are most suitable for cutting and turning on the medium and for shunting applications, but in accordance with the applicable nature and sealing surface erosion resistance, sometimes also used for throttling. As the plug seal between the movement with a wipe action, while fully open, you can completely prevent the contact with the flow medium, it is usually also used for suspension with particles of media. Another important feature of the plug valve, it is easy to adapt to multi-channel structure, so that a valve can get two, three, or even four different flow channels. This simplifies the design of the piping system, reduces the amount of valve used, and some connecting fittings needed in the equipment.Plug valves use:Plug valves are widely used in oil production, transportation and refining equipment, but also widely used in petroleum, chemical, chemical, gas, liquefied petroleum gas, HVAC and general industries.

- Q: What does one inch of an ice ball refer to?

- An inch refers to the valve's medium channel is%%C25mm

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2004 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; MidEast; Africa; Oceania; East Asia; Europe; Japan; Southeast Asia |

| Company Certifications | ISO 9001:2008; CE; API-6D |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Wenzhou |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 101-200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 8000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Forged Steel Full Bore High Pressure Ball Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords