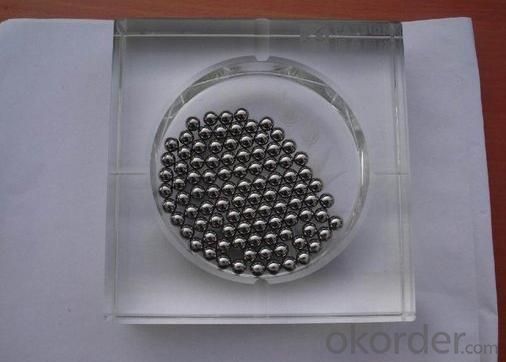

8mm 430 Stainless Steel Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Ball

MAIN PRODUCTS:

1. Material: AISI304, 316L, 420C, 430, 440C

2. Steel ball, with material AISI 1008-1086.

3. Chrome steel ball,with material: AISI52100

4. Flying saucer steel ball

5. Precision casting, including auto parts, machine parts, hardware handles, etc.

CHARACTER OF PRODUCTS:

1.The Grade of our products is from G10 to G1000

2.The dimension is from 0.5 mm to 25.4 mm.

3.The products from us are widely used in several industries, such as hardware, sliders, ball bearing lead screw, wheels, toys, bicycles, bearings, trust bearings pulleys, chemical industries, etc.

DETAIL SPECIFICATION:

|

Item |

SS304,316L,420C,440C Stainless steel ball |

|

Category |

Stainless Steel Ball |

|

Material |

AISI 420 430 440 SS304 316L |

|

Size |

0.5mm--25.4mm, 1/4",3/16",5/32",1/8",7/32",5/16",7/8",1" |

|

Grade |

G100-G3000 |

|

Hardness ( HRC) |

HRC58-65 |

|

Application |

Bicycle, bearing, pulley, slide, handcraft, shelf, luggage, hardware, grinding media |

|

Standard |

GB/T-308-2002, GB/T1148-93 |

|

Matched Standard |

DIN, JIS, ASME |

|

Certification |

ISO |

|

Packing |

Oily packing in pouch packing,plastic/tin box packing 1, 25kg/carton with steel pallet packing 2,25kg/carton without steel pallet packing 3,10kg/box then in wooden case packing 4,250kg/ steel drum packing or according to customers' requirement |

|

Place of original |

Shandong province, China |

|

Delivery |

Within 30 days or confirmed while placing order |

- Q:Are stainless steel balls resistant to acidic environments?

- Yes, stainless steel balls are generally resistant to acidic environments. The high content of chromium in stainless steel provides a protective layer that helps resist corrosion when exposed to acids. However, the level of resistance may vary depending on the specific grade and concentration of the acid.

- Q:How do stainless steel balls compare to chrome steel balls?

- Stainless steel balls and chrome steel balls find extensive usage in various industries, but they exhibit notable distinctions in terms of material composition and properties. Crafted from a blend of steel and chromium, accompanied by elements like nickel and molybdenum, stainless steel balls possess exceptional resistance against corrosion. This attribute renders them perfect for scenarios where exposure to moisture or chemicals is likely. Additionally, stainless steel balls are renowned for their robustness, endurance, and limited magnetic qualities. Industries such as aerospace, automotive, medical, and food processing widely employ stainless steel balls due to their corrosion resistance and hygienic characteristics. On the flip side, chrome steel balls, also referred to as bearing balls, originate from high carbon steel alloys infused with chromium. The introduction of chromium bolsters the hardness and wear resistance of the balls, making them ideal for implementation in bearings, valves, and other mechanical applications. Chrome steel balls are celebrated for their impeccable surface finish and precision, rendering them suitable for meticulous ventures. They possess magnetic properties and exhibit commendable toughness, equipping them to withstand high-impact and heavy-load conditions. Regarding pricing, stainless steel balls usually carry a higher price tag than chrome steel balls due to the additional alloying elements and the elevated production costs. Nevertheless, the selection between stainless steel balls and chrome steel balls should be dictated by the specific demands of the application and the desired attributes of the balls. In conclusion, stainless steel balls offer unparalleled corrosion resistance and non-magnetic properties, rendering them apt for situations demanding durability and hygiene. Conversely, chrome steel balls excel in hardness, wear resistance, and precision, making them a superb choice for precise mechanical applications.

- Q:Are stainless steel balls corrosion resistant?

- Indeed, stainless steel balls possess remarkable corrosion resistance. They belong to the category of alloys incorporating at least 10.5% chromium, which generates a safeguarding oxide layer on the metal's surface. This layer, acting as a barrier, effectively shields the steel beneath from encountering oxygen and moisture, the primary catalysts for corrosion. Consequently, stainless steel balls exhibit exceptional resilience against corrosion, rendering them highly suitable for diverse applications across industries like manufacturing, automotive, aerospace, and more.

- Q:What is the creep resistance of stainless steel balls?

- The creep resistance of stainless steel balls is generally high due to their strong and resilient nature. Stainless steel is known for its ability to resist deformation over time, even under high temperatures and prolonged stress. This makes stainless steel balls suitable for applications requiring long-term durability and resistance to creep or gradual deformation.

- Q:What are the different surface finishes available for stainless steel balls?

- There are several different surface finishes available for stainless steel balls, each offering unique properties and aesthetics. Some of the most common finishes include: 1. Shiny or Mirror Finish: This finish is achieved by polishing the surface of the stainless steel ball to a high level of reflectivity. It results in a smooth and glossy appearance, making the ball highly reflective and visually appealing. 2. Satin or Brushed Finish: This finish is obtained by brushing the surface of the stainless steel ball with a fine abrasive material in a consistent pattern. It creates a soft, linear texture that is less reflective than a shiny finish but still provides a sleek and contemporary look. 3. Matte or Bead Blasted Finish: This finish is achieved by blasting the stainless steel ball with tiny glass beads or ceramic particles at high velocity. It creates a uniform, non-reflective surface with a slightly textured appearance. Matte finish is often chosen for its resistance to fingerprints, scratches, and other signs of wear. 4. Electropolished Finish: This finish involves immersing the stainless steel ball in an electrolyte solution and applying an electrical charge to remove a thin layer of material from the surface. It results in a smooth, bright, and corrosion-resistant finish that is ideal for applications requiring high hygiene standards, such as food processing or medical devices. 5. Passivated Finish: This finish is achieved by immersing the stainless steel ball in a passivating acid solution to remove any free iron or contaminants from the surface. It enhances the corrosion resistance of the stainless steel and leaves a clean, oxide-free surface. These are just a few examples of the different surface finishes available for stainless steel balls. The choice of finish depends on the specific requirements of the application, such as aesthetics, corrosion resistance, and durability.

- Q:What's the difference between 3Cr13 stainless steel grinding rod and 420F stainless steel grinding rod?

- 420F stainless steel grinding rod has a certain wear resistance and corrosion resistance, higher hardness, its price is a lower class of stainless steel ball, applicable to stainless steel in general requirements of the working environment. Apply to all kinds of precision machinery, bearings, electrical, equipment, instruments, meters, transportation, household appliances, etc.. Often used in manufacturing atmospheres, steam, water, and oxidizing acid corrosion parts. 420F stainless steel after quenching, high hardness, good corrosion resistance (magnetic).

- Q:What's the inside diameter of DN50 stainless steel ball valve?

- If the diameter, whether it is foreign or national standard, Japanese standard. American Standard, what are generally 50mm.

- Q:Can stainless steel balls be used in sports equipment, such as ball bearings?

- Yes, stainless steel balls can be used in sports equipment, including ball bearings. Stainless steel balls are preferred in many sports applications due to their durability, corrosion resistance, and high impact resistance. These qualities make them suitable for use in ball bearings that are utilized in a wide range of sports equipment, such as bicycles, skateboards, rollerblades, and even in some sports balls like golf balls and table tennis balls. Stainless steel balls provide smooth and reliable movement, ensuring optimal performance and longevity of the sports equipment.

- Q:Can stainless steel balls be used in renewable energy systems?

- Yes, stainless steel balls can be used in renewable energy systems. They are often used in various applications such as bearings, valves, and turbines, where their corrosion resistance, durability, and high strength make them suitable for withstanding harsh environments and providing reliable performance.

- Q:What are the different sizes of stainless steel balls available?

- The sizes of stainless steel balls vary depending on the specific needs and applications. They can range from small sizes, such as 1mm or 2mm, to larger sizes, such as 20mm or 30mm. The availability of sizes may also depend on the supplier or manufacturer.

1. Manufacturer Overview |

|

|---|---|

| Location | Changsha,China |

| Year Established | 2003 |

| Annual Output Value | Above US$36 billion |

| Main Markets | Mid East;Western Europe;North America |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Changsha |

| Export Percentage | 0.8 |

| No.of Employees in Trade Department | 160,000 People |

| Language Spoken: | English;Chinese;Japanese |

| b)Factory Information | |

| Factory Size: | Above 3,000,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

8mm 430 Stainless Steel Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons pc

- Supply Capability:

- 1000 Tons Per Month pc/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords