Best Quality for Stainless Steel Channels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Channels

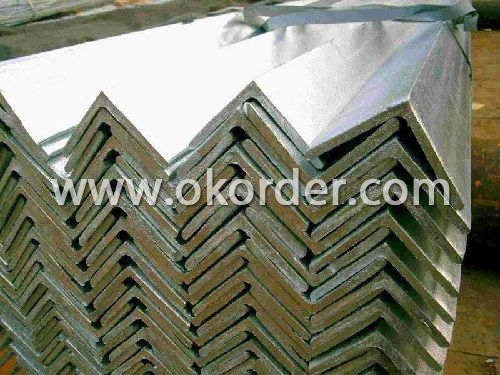

General Information of Stainless Steel Channels

Stainless Steel Channel, is ideal for all applications where greater strength and superior corrosion resistance is required. Stainless Channel has a durable dull, mill finish that is widely used for all types of fabrication projects that are exposed to the elements -chemical, acidic, fresh water, and salt water environments.

The standard length for most size channel is 12’-14’ random lengths, but lengths are available in some sizes up to 20’ and longer. Finishes on channel can vary and include cold drawn, center less ground, smooth turned, rough turned, turned ground and polished, and HRAP.

1. We will custom saw cut to length

2. DEFARS or domestic material available in many sizes

3. Polishing services are available

Specification of Stainless Steel Channels

Product Name | Stainless Steel Channel |

Standard | JIS, ASTM, GB, DIN, EN, AISI. |

Grade | 301,302,303,304,304L,305,309S,310S,316,316L,317,317L,321,347 631. |

Diameter | 75x30x6mm many other sizes can be done |

Length | 1m~6m |

Package Detail | Export standard package, bundled or be required. The inner size of container is below: 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM |

Delivery Time | Normally according to the order quantity or upon negotiation. |

Payment Terms | L/C, T/T. |

Application | Food stuff, gas, metallurgy, biology, electron, chemical, petroleum, boilers, nuclear, energy, construction field, ships building industry, war and electricity industry, boiler heat exchanger, machi-nery and hardware fields and medical equipment, fertilizer, e-tc. |

Contact | Our products are very popular because of high-quality and reasonable prices. If you are interested in any of our products, ple-ase feel free to contact us for more information. |

- Q: What are the common installation methods for stainless steel channels?

- Stainless steel channels can be installed in several ways, depending on the application and desired outcome. Here are some commonly employed methods: 1. Welding: To achieve a strong and secure connection, many opt for welding. This involves fusing the stainless steel channel to the supporting structure using a welding machine. Welding is especially favored in industrial or heavy-duty settings where strength is paramount. 2. Mechanical Fasteners: Another frequently used method involves utilizing mechanical fasteners like screws, bolts, or rivets. This straightforward approach allows for easy disassembly if necessary, making it suitable for applications that require frequent maintenance or adjustments. 3. Adhesive Bonding: In situations where welding is not feasible or a more aesthetically pleasing installation is desired, adhesive bonding comes into play. This method entails using a high-strength adhesive to attach the stainless steel channel to the supporting structure. It is commonly employed in architectural or lightweight structures. 4. Clamp-on Mounting: Clamp-on mounts offer a versatile and adjustable installation method. By using clamps or brackets, the stainless steel channel can be securely fastened to the supporting structure. This method allows for easy repositioning if needed. 5. Magnetic Mounting: For temporary installations or situations where drilling or welding is not possible, magnetic mounting provides a quick and easy solution. Powerful magnets are used to attach the stainless steel channel to a metal surface, eliminating the need for drilling or welding. Ultimately, the choice of installation method for stainless steel channels depends on factors such as the specific application, load requirements, aesthetic preferences, and available installation skills. It is crucial to carefully consider these factors before selecting the most suitable installation method.

- Q: What are the seismic performance capabilities of stainless steel channels?

- Stainless steel channels have excellent seismic performance capabilities. Due to their high strength and ductility, stainless steel channels can withstand severe seismic forces without undergoing significant deformation or failure. The unique properties of stainless steel, such as its resistance to corrosion and fire, also contribute to its superior seismic performance. One of the key advantages of stainless steel channels is their ability to absorb and dissipate energy during seismic events. This is essential in reducing the impact of seismic forces on structures and preventing structural damage. Stainless steel channels have a high yield strength, which allows them to withstand large deformations without fracturing. This ductility enables the channels to absorb seismic energy and deform in a controlled manner, thereby protecting the integrity of the overall structure. Moreover, stainless steel channels have a unique self-centering characteristic, which means that they tend to return to their original position after being subjected to seismic forces. This property significantly reduces the need for post-earthquake repairs and increases the resilience of structures. Another advantage of stainless steel channels is their resistance to corrosion. Corrosion can weaken the structural integrity of conventional steel components, making them more susceptible to failure during seismic events. However, stainless steel channels are highly resistant to corrosion, even in harsh environments, ensuring that their seismic performance capabilities are maintained over the long term. Furthermore, stainless steel channels have excellent fire resistance properties. In the event of a fire, stainless steel channels retain their strength and integrity, unlike other materials that may degrade or melt under high temperatures. This fire resistance enhances the overall seismic performance of structures, as it prevents the collapse of key load-bearing elements. In summary, stainless steel channels possess exceptional seismic performance capabilities. Their high strength, ductility, energy absorption, self-centering behavior, corrosion resistance, and fire resistance make them an ideal choice for seismic design. By utilizing stainless steel channels in construction, engineers can ensure the safety and durability of structures in seismic-prone areas.

- Q: What are the load-bearing characteristics of stainless steel channels?

- Stainless steel channels are known for their excellent load-bearing characteristics, making them a popular choice in various construction and industrial applications. The load-bearing characteristics of stainless steel channels are primarily determined by the material's physical properties, such as its strength, stiffness, and resistance to deformation. Stainless steel channels possess high tensile strength, which allows them to withstand heavy loads without deforming or breaking. This property makes them suitable for supporting structural elements, such as beams or columns, in buildings or bridges. Additionally, stainless steel channels exhibit excellent resistance to corrosion, ensuring their durability and longevity even in harsh environments. The stiffness of stainless steel channels also contributes to their load-bearing capabilities. They have a high modulus of elasticity, meaning they can resist deformation under applied loads. This stiffness helps distribute the load evenly across the channel, minimizing the risk of localized failure or buckling. Furthermore, stainless steel channels often have a consistent cross-sectional shape, which allows for efficient load transfer. The uniformity in shape and dimensions facilitates easy installation and ensures that the load is evenly distributed along the length of the channel. In summary, stainless steel channels possess high tensile strength, stiffness, and resistance to deformation, making them reliable load-bearing elements. Their ability to withstand heavy loads and resist corrosion makes them suitable for a wide range of structural applications, providing strength and stability to various construction projects.

- Q: Are stainless steel channels suitable for framing walkways or platforms?

- Yes, stainless steel channels are suitable for framing walkways or platforms. Stainless steel is a durable and corrosion-resistant material that can withstand heavy loads and provide a stable and secure structure for walkways or platforms. Its strength and resistance to rust make it a reliable choice for such applications.

- Q: Are stainless steel channels available in different lengths?

- Yes, stainless steel channels are available in a variety of lengths to suit different needs and applications.

- Q: What are the different structural configurations possible with stainless steel channels?

- Stainless steel channels can be manufactured in various structural configurations to cater to different applications and design requirements. Some of the common configurations include: 1. C-shaped Channels: These channels have a symmetrical cross-section resembling the letter "C". They are widely used for structural support, framing, and reinforcement purposes. C-channels provide excellent load-bearing capabilities and are commonly used in construction, industrial, and architectural applications. 2. U-shaped Channels: U-channels have a U-shaped cross-section and are also known as U-bars or U-beams. These channels are often utilized for edge protection, framing, and retaining purposes. U-channels offer good structural stability and are commonly used in construction, automotive, and manufacturing industries. 3. J-shaped Channels: J-channels have a J-shaped cross-section and are commonly used for holding or securing objects. These channels are often used in the installation of glass panels, mirrors, and wall claddings where they provide a concealed mount for a clean and seamless appearance. 4. Hat-shaped Channels: Hat channels, also known as H-channels or Hat purlins, have a distinctive cross-section resembling a hat or a cap. These channels are primarily used in the construction industry for roof and wall framing applications. Hat channels provide structural support, enhance stability, and improve load-bearing capabilities. 5. Miscellaneous Profiles: Apart from the aforementioned configurations, stainless steel channels can be customized into various other profiles based on specific requirements. Some examples include uneven or tapered channels, custom-designed profiles, and specialized shapes for specific industries such as marine, aerospace, or automotive. It is important to note that the specific structural configuration chosen for stainless steel channels depends on factors such as the intended application, load requirements, environmental conditions, and aesthetic preferences. Consulting with a professional engineer or supplier is recommended to ensure that the appropriate structural configuration is selected for a specific project or application.

- Q: Can stainless steel channels be used for wall cladding?

- Yes, stainless steel channels can be used for wall cladding. Stainless steel is a durable and corrosion-resistant material, making it suitable for applications such as wall cladding. Stainless steel channels can provide a sleek and modern appearance to walls, and they are easy to install and maintain. Additionally, stainless steel channels offer excellent strength and structural support, ensuring that the cladding remains secure and in place. Overall, stainless steel channels are a great choice for wall cladding due to their durability, aesthetic appeal, and ease of installation.

- Q: Are stainless steel channels suitable for high-temperature applications?

- Yes, stainless steel channels are suitable for high-temperature applications. Stainless steel is known for its excellent heat resistance properties, making it an ideal material for use in high-temperature environments. It can withstand temperatures up to 1200°C (2192°F) depending on the grade of stainless steel used. Additionally, stainless steel channels have high strength and excellent corrosion resistance, which further enhances their suitability for high-temperature applications. They are commonly used in industries such as aerospace, chemical processing, power generation, and furnace manufacturing, where high temperatures are encountered.

- Q: Are stainless steel channels resistant to alkali attacks?

- Yes, stainless steel channels are generally resistant to alkali attacks. Stainless steel is known for its exceptional resistance to corrosion, making it a popular choice for various applications in industries such as chemical processing, food processing, and construction. Alkalis, which are strong bases, can cause corrosion in certain metals, but stainless steel contains a high percentage of chromium, which forms a protective oxide layer on its surface. This oxide layer acts as a barrier, preventing alkalis from coming into direct contact with the underlying metal, thus providing excellent resistance to alkali attacks. However, it is important to note that the resistance of stainless steel channels to alkali attacks may vary depending on the specific grade of stainless steel used and the concentration and temperature of the alkali solution. Therefore, it is advisable to consult with a materials engineer or refer to specific corrosion resistance data for accurate and detailed information.

- Q: What are the maximum temperature limits for stainless steel channels?

- The maximum temperature limits for stainless steel channels depend on the specific grade of stainless steel used. However, most stainless steel grades can generally withstand temperatures up to approximately 1600°F (870°C) without significant deformation or structural damage. It is important to consult the manufacturer's specifications and guidelines for the specific grade of stainless steel being used to determine its maximum temperature limits.

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | 2000 |

| Annual Output Value | Above US$8.3 Million |

| Main Markets | Europe, America |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for Stainless Steel Channels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords