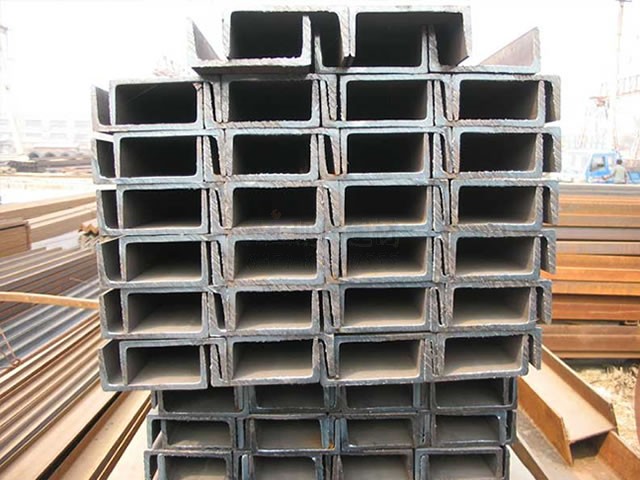

Stainless Steel U-Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Stainless Steel U-Channels at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Stainless Steel U-Channels are ideal for structural applications and general fabricating, as well as transportation and engineering.

Product Advantages:

OKorder's Steel Channels are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (15-30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Lighter than concrete

· Professional Service

· Competitive pricing

Product Specifications:

Process: Cold drawn, hot rolled

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: 201, 304, 316, 316L, 321

Height: 90 – 400mm

Thickness: 0.4 – 4mm

Length: 6m, as per customer request

Max Dimensions: 40*20*200*100mm

Surface: Bright, polished, peeled

Place of Origin: Tianjin, China

MOQ: 1 ton

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do stainless steel channels contribute to LEED points or green building certifications?

- There are several ways in which stainless steel channels can contribute to LEED points or green building certifications. Firstly, the use of stainless steel channels ensures that structures will have a longer lifespan compared to those made with other materials. This means that there will be less need for frequent replacements or repairs, resulting in a significant reduction in waste generation and environmental impact. In addition, stainless steel is a fully recyclable material, which means that it can be easily recycled and used to produce new stainless steel products at the end of its life cycle. This contributes to the overall sustainability of a building and helps reduce the demand for new raw materials, conserving natural resources. Furthermore, stainless steel channels have excellent corrosion resistance properties, eliminating the need for additional protective coatings or treatments. This reduces the use of potentially harmful chemicals and coatings, promoting a healthier indoor environment and minimizing the release of volatile organic compounds (VOCs). Moreover, stainless steel is an inert material, meaning it does not release any chemicals or toxins into the environment. This enhances indoor air quality and contributes to the overall health and well-being of building occupants. Lastly, stainless steel channels are often manufactured using a high percentage of recycled content, further reducing the environmental impact associated with their production. The use of materials with recycled content demonstrates a commitment to sustainable practices and can earn additional LEED points or green building certifications. In conclusion, stainless steel channels contribute to LEED points or green building certifications by providing durability, recyclability, corrosion resistance, improved indoor air quality, and the use of recycled content. These characteristics align with the principles of sustainable construction and help create environmentally-friendly buildings.

- Q: Can stainless steel channels be used for structural purposes?

- Yes, stainless steel channels can be used for structural purposes. Stainless steel is known for its strength, durability, and corrosion resistance, making it an ideal material for structural applications. Stainless steel channels can provide structural support, stability, and load-bearing capabilities in various industries such as construction, engineering, and architecture.

- Q: Can stainless steel channels be used in the construction of bus shelters?

- Yes, stainless steel channels can be used in the construction of bus shelters. Stainless steel is a durable material that can withstand various weather conditions, making it suitable for outdoor structures like bus shelters. Its corrosion resistance and strength make it a reliable choice for this purpose. Additionally, stainless steel channels offer versatility in design and can be customized to meet specific requirements of bus shelter construction.

- Q: What are the different load distribution mechanisms for stainless steel channels?

- The different load distribution mechanisms for stainless steel channels include uniform load distribution, concentrated load distribution, and combination load distribution. Uniform load distribution spreads the load evenly across the entire length of the channel. Concentrated load distribution focuses the load on specific points or sections of the channel. Combination load distribution involves a combination of both uniform and concentrated load distribution, depending on the specific design and application requirements.

- Q: Can stainless steel channels be used for bridges or infrastructure projects?

- Bridges and infrastructure projects can utilize stainless steel channels, as they are durable and resistant to corrosion. This material is highly suitable for various applications due to its ability to withstand harsh environmental conditions, such as moisture, chemicals, and extreme temperatures, without rusting or deteriorating. The use of stainless steel channels provides structural support and reinforcement for bridges, walkways, and infrastructure frameworks. Furthermore, the attractive appearance of stainless steel can enhance the visual appeal of these projects. In conclusion, stainless steel channels offer a dependable and enduring option for the construction of bridges and infrastructure.

- Q: What industries commonly use stainless steel channels?

- Stainless steel channels are widely used across various industries due to their exceptional durability, corrosion resistance, and versatility. Some of the industries that commonly utilize stainless steel channels include construction, architecture, automotive, manufacturing, and food processing. In the construction industry, stainless steel channels are used for structural support, framing, and reinforcement in buildings, bridges, and infrastructure projects. They provide strength and stability while withstanding harsh weather conditions and maintaining their integrity over time. Architects and interior designers often incorporate stainless steel channels in their projects to create aesthetically pleasing and modern designs. These channels are used for decorative purposes, such as handrails, balustrades, and trims, adding a touch of elegance and sophistication to various structures. The automotive industry also relies on stainless steel channels for various applications. They are commonly used in the manufacturing of vehicle frames, chassis, and suspension systems. Stainless steel channels provide the required strength and resistance to corrosion, ensuring the longevity and reliability of vehicles. Manufacturing industries, including machinery, equipment, and electronics, utilize stainless steel channels in the production and assembly of components. These channels are used for mounting and supporting equipment, providing a sturdy and stable base for machinery. Another important industry that heavily relies on stainless steel channels is the food processing industry. Stainless steel is highly hygienic and resistant to corrosion, making it ideal for applications in food processing plants. Stainless steel channels are used for creating conveyors, shelves, and other equipment that come into direct contact with food, ensuring a safe and clean processing environment. Overall, stainless steel channels find extensive use in a wide range of industries due to their exceptional properties, making them a preferred choice for various applications that require strength, durability, corrosion resistance, and aesthetic appeal.

- Q: What are the load distribution capabilities of stainless steel channels?

- Due to their strength and structural integrity, stainless steel channels exhibit exceptional load distribution capabilities. They have been designed to effectively distribute and uphold heavy loads, making them appropriate for a wide range of applications in construction, engineering, and industrial environments. The load distribution capabilities of stainless steel channels primarily rely on their dimensions and the grade of stainless steel employed. Stainless steel channels are available in various sizes and thicknesses, enabling customization to fulfill specific load requirements. The load that can be distributed increases as the channel becomes thicker. Stainless steel channels are renowned for their high tensile strength, enabling them to endure heavy loads without undergoing deformation or buckling. This renders them perfect for applications wherein load distribution plays a critical role, such as supporting beams, frames, and structures. Furthermore, stainless steel possesses corrosion resistance properties, rendering it suitable for both indoor and outdoor applications. It can withstand harsh surroundings and exposure to moisture, ensuring long-lasting load distribution capabilities. To summarize, stainless steel channels offer exceptional load distribution capabilities owing to their strength, structural integrity, and corrosion resistance. They are adaptable and dependable components that efficiently distribute heavy loads, providing stability and support in diverse applications.

- Q: Are stainless steel channels suitable for architectural detailing?

- Indeed, architectural detailing can be executed using stainless steel channels. Stainless steel, renowned for its enduring nature, robustness, and immunity to corrosion, is an optimal substance for a multitude of architectural uses. By employing stainless steel channels, one can fashion sophisticated and contemporary designs for architectural elements such as handrails, staircases, door frames, window frames, and ornamental embellishments. Furthermore, stainless steel channels can be effortlessly manipulated and tailored to meet precise design prerequisites, enabling architects and designers to conceive exclusive and visually captivating structures. The combination of aesthetic allure and pragmatic advantages renders stainless steel channels a favored selection for architectural detailing.

- Q: Can stainless steel channels be used for supporting conveyor systems?

- Yes, stainless steel channels can be used for supporting conveyor systems. Stainless steel is known for its high strength, durability, and resistance to corrosion, making it an excellent choice for industrial applications such as conveyor systems. Stainless steel channels provide structural support and stability to the conveyor system, ensuring smooth and efficient operation. Additionally, stainless steel channels have a sleek and clean appearance, which is beneficial in industries where hygiene and cleanliness are crucial, such as food processing or pharmaceuticals. Overall, stainless steel channels are a reliable and effective solution for supporting conveyor systems.

- Q: Can stainless steel channels be used for mezzanine flooring systems?

- Indeed, mezzanine flooring systems can utilize stainless steel channels. With their durability and resistance to corrosion, stainless steel emerges as a viable material for a range of applications, including mezzanine flooring. Not only do stainless steel channels provide structural support, but they also possess the ability to withstand heavy loads, making them an optimal selection for mezzanine flooring systems. Furthermore, the sleek and contemporary appearance of stainless steel contributes to the overall aesthetic enhancement of the mezzanine space. In summary, stainless steel channels present a combination of strength, durability, and visual appeal, rendering them a fitting choice for mezzanine flooring systems.

Send your message to us

Stainless Steel U-Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords