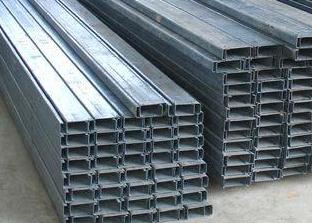

Prime Stainless Steel Channels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Channel

1.Size: 3mm to 24mm Thickness

2.Material:SUS201,202,301,304,304L,316,316L ,321 etc.

3.Length: 4m to 6m,or according to the customer's requirement

4.Standard: AISI,JIS,GB,DIN

5.Finish: Cold Drawn ,hot rolled & Polishing

6.Testing: Each heat number and batch must be tested for both chemical and mechanical properties

7.Application: Produce screw and nut, engine parts, indoor and outdoor decorating,etc.

|

Size (mm) |

Thickness (mm) | ||||||||

|

H×B |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

|

Mass (Kg/m) | |||||||||

|

40×20 |

1.79 |

|

|

|

|

|

|

|

|

|

50×25 |

2.27 |

|

|

|

|

|

|

|

|

|

60×30 |

2.74 |

3.56 |

4.37 |

5.12 |

|

|

|

|

|

|

70×35 |

3.23 |

4.21 |

5.17 |

6.08 |

|

|

|

|

|

|

80×40 |

3.71 |

4.84 |

5.96 |

7.03 |

|

|

|

|

|

|

90×45 |

4.25 |

5.55 |

6.83 |

8.05 |

|

|

|

|

|

|

100×50 |

4.73 |

6.18 |

7.62 |

8.98 |

10.3 |

11.7 |

13 |

41.2 |

|

|

120×60 |

|

|

9.2 |

10.9 |

12.6 |

14.2 |

|

|

|

|

130×65 |

|

|

10.1 |

11.9 |

13.8 |

15.5 |

17.3 |

19.1 |

|

|

140×70 |

|

|

|

12.9 |

14.9 |

16.8 |

18.8 |

20.7 |

|

|

150×75 |

|

|

|

13.9 |

16 |

18.1 |

20.2 |

22.2 |

26.3 |

|

160×80 |

|

|

|

14.8 |

17.1 |

19.3 |

21.6 |

23.8 |

28.1 |

|

180×90 |

|

|

|

16.7 |

19.4 |

22 |

24.5 |

27 |

32 |

|

200×100 |

|

|

|

18.6 |

21.6 |

24.5 |

27.4 |

30.2 |

35.8 |

- Q: What are the different types of connections available for stainless steel channels?

- There are several types of connections commonly used for stainless steel channels, including welding, bolting, and adhesive bonding. Welding involves melting the base metal of the channel and joining it with another piece of metal through fusion. Bolting uses bolts or screws to secure the channels together, providing a strong and easily reversible connection. Adhesive bonding involves using specialized adhesives to bond the channels together, creating a strong and visually seamless connection. Each type of connection has its advantages and suitability depending on the specific application and desired outcome.

- Q: What is the acoustic performance of stainless steel channels?

- The acoustic performance of stainless steel channels can vary depending on the specific design and application. Generally, stainless steel channels have good acoustic properties due to their dense and rigid nature. They have the ability to effectively block and absorb sound waves, reducing the transmission of noise. Additionally, stainless steel channels can be engineered with different profiles and thicknesses to further enhance their acoustic performance. However, it is important to note that other factors such as the surrounding environment, installation methods, and additional acoustic treatments can also influence the overall acoustic performance of stainless steel channels.

- Q: What is the weight per foot/meter of stainless steel channels?

- The weight per foot/meter of stainless steel channels varies depending on the specific dimensions and thickness of the channel. Stainless steel channels are available in different sizes and gauges, and each size will have a different weight per foot/meter. To determine the weight per foot/meter of a specific stainless steel channel, you would need to refer to the manufacturer's specifications or consult a reference guide that provides weight measurements for various stainless steel channel sizes.

- Q: Can stainless steel channels be used for supporting industrial piping systems?

- Yes, stainless steel channels can be used for supporting industrial piping systems. Stainless steel is known for its durability, strength, and corrosion resistance, making it an ideal material for supporting heavy loads. Stainless steel channels are typically designed to provide structural support and stability to the piping system, ensuring that it remains securely in place. Additionally, stainless steel channels can withstand high temperatures and harsh environments, making them suitable for various industrial applications.

- Q: Can stainless steel channels be used for curtain walls?

- Yes, stainless steel channels can be used for curtain walls. Stainless steel is a durable and corrosion-resistant material, making it suitable for exterior applications such as curtain walls. It offers structural stability and can withstand various weather conditions, making it a popular choice for modern architectural designs.

- Q: Are stainless steel channels resistant to impact or vibration?

- Indeed, stainless steel channels typically exhibit resistance against impact and vibration. Renowned for its robustness and durability, stainless steel proves to be an appropriate material for applications demanding such resistance. Moreover, stainless steel boasts exceptional fatigue strength, enabling it to endure repetitive loading and unloading without significant distortion or failure. Nevertheless, it is crucial to acknowledge that the degree of impact and vibration resistance may fluctuate depending on various factors, including the grade and thickness of the stainless steel channel, as well as the magnitude and frequency of the impact or vibration events.

- Q: Can stainless steel channels be used in electrical applications?

- Yes, stainless steel channels can be used in electrical applications. Stainless steel is known for its high corrosion resistance, durability, and strength, making it suitable for various electrical applications where protection against environmental factors is required. Additionally, stainless steel channels can provide structural support and serve as a conduit for electrical wiring in installations such as power distribution, control panels, and cable management systems.

- Q: Can stainless steel channels be used for glass railing systems?

- Glass railing systems can indeed utilize stainless steel channels. These channels are highly favored in glass railing systems because of their robustness, long-lasting nature, and resistance to corrosion. Their specific design ensures that glass panels are securely held in place, resulting in a sleek and contemporary appearance while guaranteeing the safety of the railing system. These channels can be affixed onto various surfaces like walls or posts and are available in a range of sizes and profiles to accommodate different glass thicknesses and design preferences. Moreover, stainless steel channels can be personalized with different finishes such as brushed or polished, to seamlessly blend with the surrounding space's aesthetic. All in all, stainless steel channels present a dependable and adaptable option for glass railing systems.

- Q: Can stainless steel channels be used in architectural mesh or wire systems?

- Yes, stainless steel channels can be used in architectural mesh or wire systems. Stainless steel channels provide structural support and can be used as framing elements to hold the mesh or wire in place, creating a sturdy and aesthetically pleasing architectural feature. Additionally, stainless steel is known for its durability, corrosion resistance, and versatility, making it an ideal material choice for architectural applications.

- Q: Are stainless steel channels suitable for framing?

- Indeed, stainless steel channels are an appropriate choice for framing purposes. Boasting robustness and longevity, stainless steel proves to be an exceptional material that offers exceptional structural reinforcement for a variety of framing applications. With its impressive strength-to-weight ratio, stainless steel stands as the perfect option for crafting frames that necessitate both solidity and lightness. Moreover, stainless steel's resistance to corrosion further adds to its advantages, particularly in areas prone to dampness or corrosive elements. Furthermore, the malleability and adaptability of stainless steel channels facilitate effortless fabrication and customization to fulfill specific framing prerequisites, providing a wealth of design possibilities. In summary, stainless steel channels emerge as an unwavering and enduring choice for any framing project.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$8 million |

| Main Markets | East Asia, Middle East, West Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | above 50 people |

| Language Spoken: | English, Chinese, Arabic |

| b) Factory Information | |

| Factory Size: | about 15000 square meter |

| No. of Production Lines | above 4 |

| Contract Manufacturing | OEM Service Offered,Design Service Offered |

| Product Price Range | Average |

Send your message to us

Prime Stainless Steel Channels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords