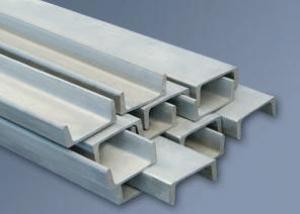

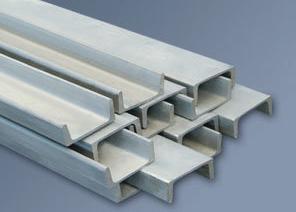

SUS304 Stainless Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Channel

1.Size: 3mm to 24mm Thickness

2.Material:SUS201,202,301,304,304L,316,316L ,321 etc.

3.Length: 4m to 6m,or according to the customer's requirement

4.Standard: AISI,JIS,GB,DIN

5.Finish: Cold Drawn ,hot rolled & Polishing

6.Testing: Each heat number and batch must be tested for both chemical and mechanical properties

7.Application: Produce screw and nut, engine parts, indoor and outdoor decorating,etc.

|

Size (mm) |

Thickness (mm) | ||||||||

|

H×B |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

|

Mass (Kg/m) | |||||||||

|

40×20 |

1.79 |

|

|

|

|

|

|

|

|

|

50×25 |

2.27 |

|

|

|

|

|

|

|

|

|

60×30 |

2.74 |

3.56 |

4.37 |

5.12 |

|

|

|

|

|

|

70×35 |

3.23 |

4.21 |

5.17 |

6.08 |

|

|

|

|

|

|

80×40 |

3.71 |

4.84 |

5.96 |

7.03 |

|

|

|

|

|

|

90×45 |

4.25 |

5.55 |

6.83 |

8.05 |

|

|

|

|

|

|

100×50 |

4.73 |

6.18 |

7.62 |

8.98 |

10.3 |

11.7 |

13 |

41.2 |

|

|

120×60 |

|

|

9.2 |

10.9 |

12.6 |

14.2 |

|

|

|

|

130×65 |

|

|

10.1 |

11.9 |

13.8 |

15.5 |

17.3 |

19.1 |

|

|

140×70 |

|

|

|

12.9 |

14.9 |

16.8 |

18.8 |

20.7 |

|

|

150×75 |

|

|

|

13.9 |

16 |

18.1 |

20.2 |

22.2 |

26.3 |

|

160×80 |

|

|

|

14.8 |

17.1 |

19.3 |

21.6 |

23.8 |

28.1 |

|

180×90 |

|

|

|

16.7 |

19.4 |

22 |

24.5 |

27 |

32 |

|

200×100 |

|

|

|

18.6 |

21.6 |

24.5 |

27.4 |

30.2 |

35.8 |

- Q: Can stainless steel channels be used for green building projects?

- Yes, stainless steel channels can be used for green building projects. Stainless steel is a sustainable and eco-friendly material that is often preferred in green building practices. It is highly durable and has a long lifespan, minimizing the need for replacements or repairs and reducing waste. Stainless steel is also resistant to corrosion, fire, and pests, which further enhances its durability and reduces the environmental impact. Additionally, stainless steel is 100% recyclable, making it a sustainable choice for green building projects. Its recyclability helps to reduce the demand for new raw materials and minimizes the amount of waste sent to landfills. Overall, stainless steel channels are a suitable option for green building projects due to their sustainability, durability, and recyclability.

- Q: Can stainless steel channels be used in the construction of machinery frames?

- Yes, stainless steel channels can be used in the construction of machinery frames. Stainless steel is a durable and corrosion-resistant material, making it suitable for heavy-duty applications. The channels provide structural support and can withstand the loads and vibrations associated with machinery operations.

- Q: Are stainless steel channels suitable for the manufacturing of conveyor systems?

- Yes, stainless steel channels are highly suitable for the manufacturing of conveyor systems. Stainless steel is a versatile and durable material that offers various benefits for conveyor systems. Firstly, stainless steel is resistant to corrosion, which is crucial in conveyor systems that are exposed to moisture, chemicals, and other corrosive substances. This corrosion resistance ensures the longevity and reliability of the conveyor system, reducing maintenance and replacement costs. Additionally, stainless steel channels provide excellent strength and structural integrity, allowing them to withstand heavy loads and high impact. This is particularly important in conveyor systems that handle large quantities of materials or operate in demanding environments. Furthermore, stainless steel channels offer a hygienic solution for conveyor systems used in industries such as food processing and pharmaceuticals. Stainless steel is non-porous and easy to clean, preventing the accumulation of bacteria, dirt, or other contaminants. This promotes product safety, quality, and compliance with industry regulations. Lastly, stainless steel channels can be fabricated into various shapes and sizes to meet specific conveyor system requirements. They can be welded, cut, and formed to create custom designs and configurations, ensuring optimal performance and efficiency. In conclusion, stainless steel channels are highly suitable for the manufacturing of conveyor systems due to their corrosion resistance, strength, hygienic properties, and customization options. They provide a reliable and long-lasting solution for a wide range of industries.

- Q: Can stainless steel channels be used for railway infrastructure?

- Indeed, railway infrastructure can make use of stainless steel channels. Renowned for its exceptional strength, resistance to corrosion, and durability, stainless steel proves to be highly suitable for a wide range of applications within the railway industry. With the implementation of stainless steel channels, one can effectively support and reinforce railway tracks, bridges, platforms, and various other structures. Thanks to stainless steel's remarkable resistance to corrosion, the occurrence of rusting and deterioration is effectively prevented, consequently guaranteeing the longevity of railway infrastructure even in harsh outdoor environments. Moreover, the reliability of stainless steel channels in railway applications is further emphasized by their ability to endure substantial loads and vibrations.

- Q: What are the different corrosion protection options for stainless steel channels?

- There are several corrosion protection options available for stainless steel channels, depending on the specific application and environmental conditions. 1. Passive layer: Stainless steel naturally forms a passive layer of chromium oxide on its surface, which provides excellent corrosion resistance in most environments. This layer can be enhanced by regular cleaning and maintenance to ensure its effectiveness. 2. Surface treatments: Various surface treatments can be applied to stainless steel channels to further enhance their corrosion resistance. These treatments include passivation, electropolishing, and pickling, which remove impurities and improve the passive layer's performance. 3. Coatings: Coating stainless steel channels with protective films or paints can provide an additional layer of barrier protection against corrosion. Epoxy, polyurethane, and powder coatings are commonly used for this purpose. These coatings should be chosen carefully to ensure compatibility with stainless steel and the intended operating conditions. 4. Cathodic protection: In more aggressive environments, cathodic protection can be employed to protect stainless steel channels. This method involves connecting the stainless steel to a sacrificial anode (usually made of zinc or magnesium) or using an impressed current system to create an electrochemical reaction that prevents corrosion. 5. Alloy selection: Depending on the specific application, selecting a higher-grade stainless steel alloy with increased corrosion resistance properties can be an effective corrosion protection option. Alloys such as duplex stainless steel or superaustenitic stainless steel offer enhanced resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking. 6. Environmental control: Controlling the surrounding environment can also help protect stainless steel channels from corrosion. This may involve maintaining proper ventilation, controlling humidity levels, and avoiding exposure to corrosive chemicals or saltwater. It is important to consider the specific requirements and conditions of the application when choosing the most suitable corrosion protection option for stainless steel channels. Consulting with corrosion experts or engineers can provide valuable guidance in selecting the appropriate method to ensure long-term durability and performance.

- Q: Can stainless steel channels be used for cable management?

- Indeed, cable management can be accomplished by utilizing stainless steel channels. With their exceptional durability and resistance to corrosion, stainless steel channels are well-suited for a range of applications, including cable management. Their effectiveness in organizing and safeguarding cables ensures an orderly and sleek appearance, while simultaneously preventing any harm or entanglement. Furthermore, stainless steel channels provide remarkable strength and stability, rendering them perfect for supporting heavy cables or multiple cables in industrial or commercial environments. Moreover, the versatility of stainless steel channels allows for customization to meet specific length and configuration requirements, offering flexible and efficient solutions for cable management.

- Q: Can stainless steel channels be used in architectural applications?

- Yes, stainless steel channels can be used in architectural applications. Stainless steel is a popular choice for architectural projects due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel channels can be used for various purposes in architectural applications, such as structural support, framing, and decorative elements. Stainless steel channels offer excellent strength and stability, making them suitable for structural applications in buildings. They can be used as beams or columns to provide support and stability to the structure. The corrosion resistance of stainless steel ensures that these channels will maintain their structural integrity even in harsh environmental conditions, such as coastal areas with high salt content. In addition to their functional uses, stainless steel channels can also be used for decorative purposes in architectural applications. The sleek and modern appearance of stainless steel adds an aesthetic appeal to any design. Architects often use stainless steel channels to create decorative features, such as handrails, trims, and accents, which enhance the overall look of a building. Furthermore, stainless steel channels are available in various sizes, shapes, and finishes, allowing architects and designers to choose the most suitable option for their specific project requirements. They can be easily fabricated and customized to meet the unique design needs of architectural applications. Overall, stainless steel channels are a versatile and reliable choice for architectural applications. Their combination of strength, corrosion resistance, and aesthetic appeal makes them an ideal material for both structural and decorative purposes in buildings.

- Q: Can stainless steel channels be used in the construction of wastewater treatment facilities?

- Yes, stainless steel channels can be used in the construction of wastewater treatment facilities. Stainless steel is a durable and corrosion-resistant material that can withstand the harsh conditions and chemicals present in wastewater treatment processes. Its high strength and resistance to corrosion make it an ideal choice for constructing channels that will transport and contain wastewater in these facilities.

- Q: How do you join stainless steel channels?

- Stainless steel channels can be joined using various methods such as welding, bolting, or adhesive bonding. Welding is the most common and preferred method, as it provides a strong and durable joint. However, it requires skilled labor and specialized equipment. Bolting is another option, which involves using bolts and nuts to secure the channels together. Adhesive bonding can also be used, where a suitable adhesive is applied to join the surfaces of the channels. The choice of joining method depends on factors such as the application, desired strength, and aesthetics.

- Q: Are stainless steel channels suitable for noise reduction applications?

- Stainless steel channels are indeed a fitting choice for applications focused on reducing noise. Renowned for their exceptional acoustic properties, including remarkable sound absorption and insulation capabilities, stainless steel is highly regarded. These channels find utility in diverse noise reduction scenarios, such as constructing sound barriers, acoustic enclosures, and acoustic panels. With their enduring nature, resistance to corrosion, and capacity to endure high temperatures, stainless steel channels prove to be a dependable option for long-lasting noise reduction solutions. Moreover, these channels can be tailored to meet particular design specifications, enabling customization and maximizing noise reduction effectiveness.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$8 million |

| Main Markets | East Asia, Middle East, West Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | above 50 people |

| Language Spoken: | English, Chinese, Arabic |

| b) Factory Information | |

| Factory Size: | about 15000 square meter |

| No. of Production Lines | above 4 |

| Contract Manufacturing | OEM Service Offered,Design Service Offered |

| Product Price Range | Average |

Send your message to us

SUS304 Stainless Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords