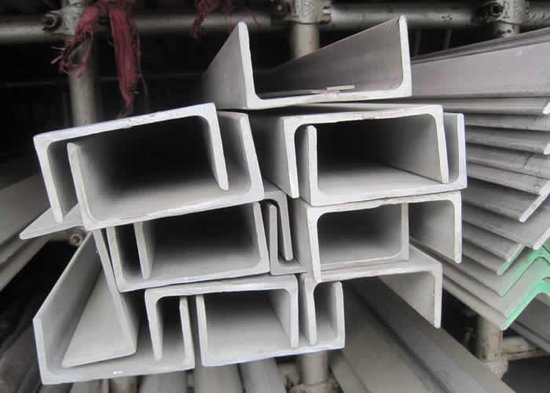

Stainless Steel Channel

- Loading Port:

- Shanghai Port or Others

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Channels

Stainless Steel Channel, is ideal for all applications where greater strength and superior corrosion resistance is required. Stainless Channel has a durable dull, mill finish that is widely used for all types of fabrication projects that are exposed to the elements - chemical, acidic, fresh water, and salt water environments

The standard length for most size channel is 12’-14’ random lengths, but lengths are available in some sizes up to 20’ and longer. Finishes on channel can vary and include cold drawn, centerless ground, smooth turned, rough turned, turned ground and polished, and HRAP.

· We will custom saw cut to length

· DEFARS or domestic material available in many sizes

· Polishing services are available

|

Product Name |

Stainless Steel Channel | |

|

Standard |

JIS, ASTM, GB, DIN, EN, AISI | |

|

Grade |

301,302,303,304,304L,305,309S,310S,316,316L,317,317L,321,347 631... | |

|

Diameter |

75x30x6mm many other sizes can be done | |

|

Length |

1m~6m |

|

|

Package Detail |

Export standard package, bundled or be required. The inner size of container is below: 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM | |

|

Delivery Time |

Normally according to the order quantity or upon negotiation | |

|

Payment Terms |

L/C, T/T | |

|

Application |

Food stuff, gas, metallurgy, biology, electron, chemical, petroleum, boilers, nuclear, energy, construction field, ships building industry, war and electricity industry, boiler heat exchanger, machiner and hardware fields and medical equipment, fertilizer, etc.

| |

|

Contact |

Our products are very popular because of high-quality and reasonable prices. If you are interested in any of our products, please feel free to contact us for more information. | |

- Q: Are stainless steel channels suitable for rooftop applications?

- Yes, stainless steel channels are suitable for rooftop applications. Stainless steel is known for its excellent corrosion resistance, durability, and strength, making it an ideal material for outdoor and rooftop applications. It can withstand harsh weather conditions, such as rain, snow, UV radiation, and extreme temperatures, without rusting or deteriorating. Additionally, stainless steel channels offer structural stability and support, making them suitable for rooftop installations where weight-bearing capacity is required. They are often used in rooftop solar panel installations, HVAC systems, and rooftop walkways, among other applications.

- Q: Can stainless steel channels be painted or coated for additional protection?

- Yes, stainless steel channels can be painted or coated for additional protection. While stainless steel is known for its corrosion resistance, painting or coating the channels can offer an extra layer of protection against environmental factors such as moisture, chemicals, or UV radiation. The paint or coating can provide a barrier between the stainless steel surface and potential corrosive agents, extending the lifespan of the channels and enhancing their aesthetic appearance. Additionally, painting or coating stainless steel channels can help match the surrounding environment or provide color-coded identification for specific applications. It is important to choose a paint or coating that is compatible with stainless steel and to properly prepare the surface before applying the protective layer to ensure proper adhesion and durability.

- Q: Are stainless steel channels easy to transport?

- Yes, stainless steel channels are generally easy to transport. Stainless steel is known for its strength and durability, making it a reliable material for transportation purposes. Additionally, stainless steel channels are often designed in various lengths and sizes, which allows for easy handling and maneuvering during transportation. Furthermore, stainless steel is resistant to corrosion and rust, ensuring that the channels will remain in good condition even when exposed to different weather conditions during transportation. Overall, the characteristics of stainless steel make it an ideal material for easy and hassle-free transportation of channels.

- Q: Can stainless steel channels be used for agricultural or farming structures?

- Yes, stainless steel channels can be used for agricultural or farming structures. Stainless steel is highly resistant to corrosion, which makes it suitable for use in agricultural environments where exposure to moisture, chemicals, and other corrosive elements is common. Stainless steel channels are durable, strong, and can withstand harsh conditions, making them ideal for constructing barns, sheds, fences, and other structures on farms. Additionally, stainless steel is easy to clean and maintain, ensuring longevity and hygiene in agricultural settings.

- Q: What are the different ways to connect stainless steel channels at corners or intersections?

- There are multiple options for connecting stainless steel channels at corners or intersections, depending on the project's specific requirements. Here are some commonly used techniques: 1. Welding: Welding is a popular and effective method that involves heating the metal and fusing the channels together using a welding rod or wire. This creates a durable and robust connection. 2. Bolting: Another commonly employed technique is using bolts to connect the stainless steel channels. This requires drilling holes in the channels and securing them together with bolts and nuts. Bolting provides a strong connection that is easily removable if necessary. 3. Adhesive bonding: In certain cases, adhesive bonding can be used to connect stainless steel channels. Specialized adhesives designed for metal bonding are used to create a reliable and sturdy connection. However, it is crucial to ensure that the adhesive is compatible with stainless steel and can withstand the intended load and conditions. 4. Mechanical fasteners: Mechanical fasteners, such as screws, rivets, or clips, can also be utilized to connect stainless steel channels at corners or intersections. These fasteners are easy to install and provide a secure connection. However, the choice of mechanical fasteners should be based on the load requirements and specific application. 5. Interlocking joints: Some stainless steel channels come equipped with interlocking joints that allow for easy connection at corners or intersections. These joints typically feature a male and female connection that can be easily slid or snapped together, providing a quick and efficient connection method. Overall, the choice of connecting method for stainless steel channels at corners or intersections depends on factors like load requirements, aesthetic preferences, ease of installation, and specific project needs. It is essential to carefully consider these factors and seek professional advice to determine the most suitable method for your application.

- Q: How do I clean and maintain stainless steel channels?

- To ensure that your stainless steel channels are clean and well-maintained, you can adhere to the following guidelines: 1. Begin by eliminating any loose dirt or debris from the surface of the stainless steel channels. You can use a soft brush or a damp cloth to wipe away dust or dirt particles. 2. Subsequently, create a cleaning solution by combining warm water with a mild detergent or dish soap. It is advisable to refrain from using harsh cleaners or bleach as they may harm the stainless steel. 3. Immerse a soft cloth or sponge into the cleaning solution and gently scrub the surface of the stainless steel channels. Be thorough in cleaning both the inside and outside of the channels, paying close attention to crevices and corners. 4. Rinse the channels extensively with clean water to eliminate any remaining soap residue. This can be achieved by using a hose or a bucket of water to thoroughly rinse off the cleaning solution. 5. After rinsing, dry the channels with a clean, lint-free cloth to prevent water spots and streaks. It is crucial to ensure that the channels are completely dry to prevent potential rust or corrosion. 6. For regular maintenance, consider utilizing a stainless steel cleaner or polish to restore the channels' shine and protect their surface. Apply the cleaner as instructed by the manufacturer and buff the channels with a soft cloth until they are devoid of streaks and smudges. 7. In the event that you encounter stubborn stains or marks on the stainless steel channels, employ a non-abrasive stainless steel cleaner or create a paste using baking soda and water. Apply the cleaner or paste to the affected areas, gently scrub with a soft brush or cloth, and rinse thoroughly. 8. Lastly, it is essential to refrain from using abrasive materials, harsh chemicals, or abrasive scrubbers that may scratch or harm the surface of the stainless steel channels. Instead, opt for soft cloths, sponges, or brushes specifically designed for cleaning stainless steel. By adhering to these steps and maintaining a regular cleaning routine, you can ensure that your stainless steel channels remain clean, shiny, and free from stains or corrosion.

- Q: Can stainless steel channels be used in pharmaceutical or laboratory settings?

- Yes, stainless steel channels can be used in pharmaceutical or laboratory settings. Stainless steel is a preferred material in these industries due to its excellent corrosion resistance, high durability, and ease of cleaning. Stainless steel channels are often used for the construction of equipment, fixtures, and storage systems in pharmaceutical and laboratory settings. They are resistant to chemicals, moisture, and temperature fluctuations, making them suitable for storing, transporting, and processing various substances and materials. Additionally, stainless steel channels have a smooth, non-porous surface, which helps to prevent the buildup of bacteria and other contaminants, making them an ideal choice for maintaining a clean and hygienic environment in pharmaceutical and laboratory settings.

- Q: What are the different sizes available for stainless steel channels?

- The different sizes available for stainless steel channels vary depending on the manufacturer and the specific application. Common sizes range from small channels measuring around 1 inch to larger channels that can be several inches wide.

- Q: What are the different joining methods for stainless steel channels?

- Stainless steel channels can be joined using various methods, including welding, bolting, adhesive bonding, and mechanical fastening. 1. Welding: Welding is a commonly employed technique for joining stainless steel channels. By melting the edges of the channels and combining them with a filler metal, a sturdy and enduring joint is formed. Different welding techniques, such as TIG and MIG welding, can be utilized based on specific requirements. 2. Bolting: Bolting involves the use of bolts, nuts, and washers to secure stainless steel channels together. This method is relatively straightforward and allows for easy disassembly and reassembly when needed. It is often employed in situations requiring frequent maintenance or repairs, although it may not offer the same strength as welding in certain cases. 3. Adhesive bonding: Adhesive bonding employs special adhesive materials to bond stainless steel channels together. This method does not necessitate heat or mechanical force, making it suitable for connecting thin or delicate channels. While adhesive bonding can produce a strong and durable joint, its strength may not match that of welding or bolting in high-stress applications. 4. Mechanical fastening: Mechanical fastening involves the use of screws, rivets, or clips to join stainless steel channels. This method is commonly used when a temporary or semi-permanent joint is required. While mechanical fastening allows for easy disassembly and reassembly, it may not provide the same level of strength as welding or bolting. Ultimately, the choice of joining method for stainless steel channels depends on factors such as application requirements, required strength, joint accessibility, and desired ease of disassembly or reassembly. It is essential to carefully evaluate these factors and seek expert advice to determine the most suitable joining method for a specific application.

- Q: Can stainless steel channels be used for balcony railing systems?

- Indeed, balcony railing systems can utilize stainless steel channels. Owing to its robustness, strength, and ability to resist corrosion, stainless steel remains a favored material option for balcony railings. By supplying a solid foundation for the railing system, stainless steel channels guarantee the balcony's safety and security. Moreover, these channels can be tailored to suit the unique design and aesthetic preferences of the balcony, rendering them a versatile choice for railing systems.

Send your message to us

Stainless Steel Channel

- Loading Port:

- Shanghai Port or Others

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords