Stainless Steel Epoxy

Stainless Steel Epoxy Related Searches

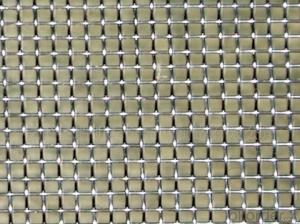

Inox Stainless Steel Esd Epoxy Stainless Steel Coating Stainless Steel Oxidize Stainless Steel Oxidized Stainless Steel Oxidation Stainless Steel Adhesive Edforce Stainless Steel Stainless Steel Alloys Stainless Steel Etching Stainless Steel Electrodes Stainless Steel Acetone Stainless Steel Elbow Oxo Stainless Steel Stainless Steel Enclosure Stainless Steel Paint Laser Etching Stainless Steel Etching Stainless Steel Stainless Steel Glue Etch Stainless Steel Stainless Steel Corrosion Stainless Steel Powder Stainless Steel Elements Stainless Steel Espresso Maker Stainless Steel Tape Stainless Steel Spray Paint Stainless Steel Roofing Stainless Steel Hardware Stainless Steel Scrubbing Stainless Steel MeshStainless Steel Epoxy Supplier & Manufacturer from China

Stainless Steel Epoxy is a type of high-performance epoxy resin that is specifically formulated to provide excellent adhesion, corrosion resistance, and durability when used with stainless steel materials. This advanced product is engineered to withstand harsh environmental conditions and is widely recognized for its ability to protect and preserve the integrity of stainless steel components in various industries.The application and usage scenarios of Stainless Steel Epoxy are quite diverse, making it an essential material in numerous industries. It is commonly used in the construction, automotive, aerospace, and marine sectors to bond, seal, and protect stainless steel components from corrosion and wear. This product is also ideal for use in environments where resistance to chemicals, water, and temperature fluctuations is crucial, ensuring the longevity and reliability of stainless steel structures and equipment.

Okorder.com is a leading wholesale supplier of Stainless Steel Epoxy, boasting a large inventory that caters to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com offers a comprehensive range of Stainless Steel Epoxy products that meet the highest industry standards. This ensures that customers can find the right product for their specific applications, backed by the assurance of prompt and reliable service.

Hot Products