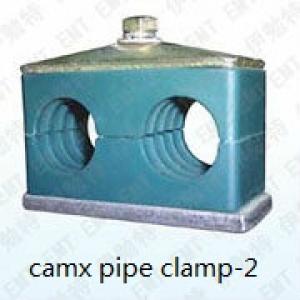

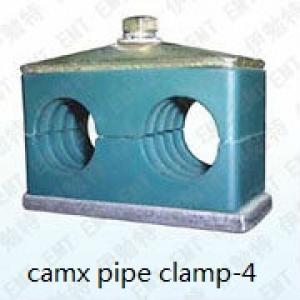

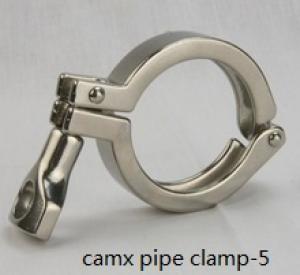

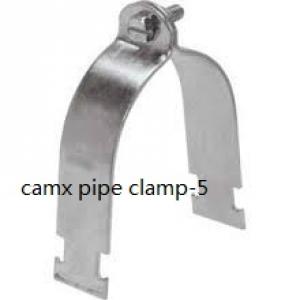

stainless steel heavy duty pipe clamp

- Loading Port:

- Qingdao

- Payment Terms:

- TT LC

- Min Order Qty:

- 100 pcs pc

- Supply Capability:

- 300000pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Usage: Pipe Clamp

Material: steel、matel;Galvanized iron ,stainles

Band width:3mm/20mm

Connection:welding

Model number:As your requirement

Structure:Swivel clamp

Certificate:ISO9001:2008

Feature:

1.Use the open internal and external circle structure,and with screw fixed.It is effectively to solve the problem that when small diameter solft tube connect the hared tube,it is easy appear dead angle,and liquid or gas leakage problem.Easy structure,Easy maked.

2.Edge is no burrfree,it is ability to prevent the tube damaged

3.By a efficiently hydrogen relief treatment,long-term use needn't to worry fracture and other problems

Surface: zinc plated Packaging

4.Accord with DIN3017 Standard.By 48 hours salt and fog test,it has a good corrosion resistance

5.By our last 48 hours elastic test,to insure a high strength mechanical properties.

6.Easy to fix.

Working Temp: -40 ℃ ~ 110 ℃

Size:3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2

Structure: Suspension Clamp and so on On-time shipment and pre-shipment product quality safeguards clamp is mainly used in automobiles,tractors, ships, gasoline engine, and so on each kind of mechanical

device for oil, gas, hydraulic hose connector, various types of

rubber tube interface must join parts fastening.

Detail: plywood case ,pallets or any other package as buyer's requirements

Delivery Detail: about 20-30days

Material: steel、matel;Galvanized iron ,stainles

Band width:3mm/20mm

Connection:welding

Model number:As your requirement

Structure:Swivel clamp

Certificate:ISO9001:2008

Feature:

1.Use the open internal and external circle structure,and with screw fixed.It is effectively to solve the problem that when small diameter solft tube connect the hared tube,it is easy appear dead angle,and liquid or gas leakage problem.Easy structure,Easy maked.

2.Edge is no burrfree,it is ability to prevent the tube damaged

3.By a efficiently hydrogen relief treatment,long-term use needn't to worry fracture and other problems

Surface: zinc plated Packaging

4.Accord with DIN3017 Standard.By 48 hours salt and fog test,it has a good corrosion resistance

5.By our last 48 hours elastic test,to insure a high strength mechanical properties.

6.Easy to fix.

Working Temp: -40 ℃ ~ 110 ℃

Size:3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2

Structure: Suspension Clamp and so on On-time shipment and pre-shipment product quality safeguards clamp is mainly used in automobiles,tractors, ships, gasoline engine, and so on each kind of mechanical

device for oil, gas, hydraulic hose connector, various types of

rubber tube interface must join parts fastening.

Detail: plywood case ,pallets or any other package as buyer's requirements

Delivery Detail: about 20-30days

- Q: How can the clamp meter measure alternating current?

- The general type for measuring current clamp meter, you open the jaw vise current wires can be, if you want to measure the AC voltage, can use the pen, with a multimeter used almost

- Q: How to use the clamp ammeters

- The measured voltage clamp meter shall not exceed the values marked on the ground, otherwise easy to cause the accident, or cause the risk of electric shock.

- Q: What are the commonly used tools for electrician maintenance?

- Kit; high voltage electroscope, low voltage test pencil; nose pliers, diagonal pliers, pliers, stripping pliers, small crimping pliers; 6 inch, 8 inch, 12 inch wrench, six angle wrench, a 8-19 wrench set, 8-19 wrench set, 32 sets of a screw sleeve; a large, medium and small trumpet cross screwdriver, screwdriver set a special instrument (now a lot of terminals to be used);

- Q: What do you mean by measuring current 2/20 and 200/600 stalls by clamp type?

- Measure the range of gears, corresponding to AC, 2 to 20 amperes, 200 to 600 Amperes

- Q: With the operation of the motor current clamp meter measuring three-phase, single-phase current is very low, what is the reason?

- Place the line in the middle of the mouth and vertical to the mouth level;

- Q: Clamp meter cable direction? Why do I change the direction of measurement with a cable, the current is not the same

- Clamp type ammeter, clamp wire, current measurement method can only measure alternating current, the battery should be charged dc.

- Q: How to measure the actual current of three-phase induction motor?

- Clamp meter is composed of a current transformer and current meter assembly. The iron core of the current transformer can be opened when the wrench is tightened; the wire through which the current is measured can be cut through the opening of the iron core without cutting off, and when the wrench is released, the iron core is closed. Through the test circuit of the core, the wire becomes the primary coil of the current transformer, in which the current is induced in the two coil through the current.

- Q: How to measure the static grounding resistance

- Measurement of grounding resistance can not use a multimeter, because the meter does not have the accuracy of this requirement, grounding resistance instrument at least 0.01 euro readings,

- Q: Automatic tripping of circuit breaker often, this is why, what to do?

- After analyzing the two causes of circuit breaker tripping, some common analysis and treatment methods are summarized. The first is to judge whether it is a circuit problem or a circuit breaker problem. The general process is:Observe whether the burning of a circuit, whether there is odor, the low voltage cabinet within the two control loop whether there is no fault1., when there is a fault point, the switch can be closed, the line problem is explained, and the circuit breaker is irrelevant.2. there is no obvious fault point, in the case of no load, the circuit breaker still can not switch on, it shows that the circuit breaker can not be put into operation, it is the problem of the circuit breaker itself.

- Q: 20kW motor running for some time will trip what is the reason?

- Is likely to open itself, if it is used for a long time in the air this phenomenon occurs, especially the switch lockage under heavy load especially, and tripping times more frequent. I suggest you change a new open space

Send your message to us

stainless steel heavy duty pipe clamp

- Loading Port:

- Qingdao

- Payment Terms:

- TT LC

- Min Order Qty:

- 100 pcs pc

- Supply Capability:

- 300000pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords