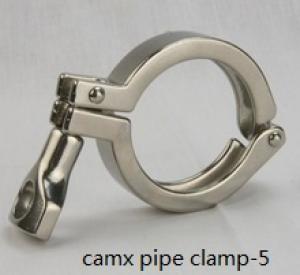

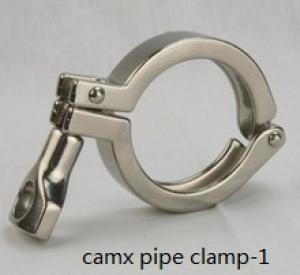

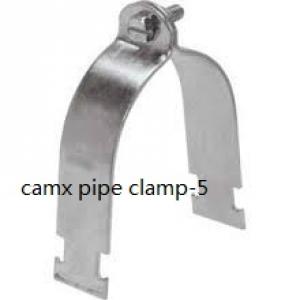

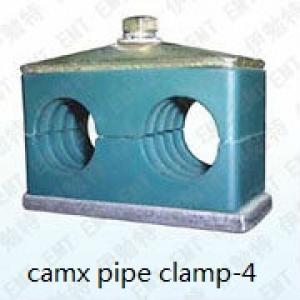

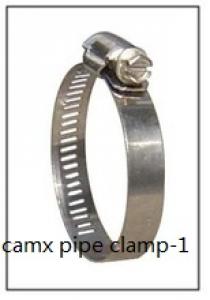

heavy duty stainless steel pipe clamp

- Loading Port:

- Qingdao

- Payment Terms:

- TT LC

- Min Order Qty:

- 100 pcs pc

- Supply Capability:

- 300000pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Usage: Pipe Clamp

Material: steel、matel;Galvanized iron ,stainles

Band width:3mm/20mm

Connection:welding

Model number:As your requirement

Structure:Swivel clamp

Certificate:ISO9001:2008

Feature:

1.Use the open internal and external circle structure,and with screw fixed.It is effectively to solve the problem that when small diameter solft tube connect the hared tube,it is easy appear dead angle,and liquid or gas leakage problem.Easy structure,Easy maked.

2.Edge is no burrfree,it is ability to prevent the tube damaged

3.By a efficiently hydrogen relief treatment,long-term use needn't to worry fracture and other problems

Surface: zinc plated Packaging

4.Accord with DIN3017 Standard.By 48 hours salt and fog test,it has a good corrosion resistance

5.By our last 48 hours elastic test,to insure a high strength mechanical properties.

6.Easy to fix.

Working Temp: -40 ℃ ~ 110 ℃

Size:3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2

Structure: Suspension Clamp and so on On-time shipment and pre-shipment product quality safeguards clamp is mainly used in automobiles,tractors, ships, gasoline engine, and so on each kind of mechanical

device for oil, gas, hydraulic hose connector, various types of

rubber tube interface must join parts fastening.

Detail: plywood case ,pallets or any other package as buyer's requirements

Delivery Detail: about 20-30days

Material: steel、matel;Galvanized iron ,stainles

Band width:3mm/20mm

Connection:welding

Model number:As your requirement

Structure:Swivel clamp

Certificate:ISO9001:2008

Feature:

1.Use the open internal and external circle structure,and with screw fixed.It is effectively to solve the problem that when small diameter solft tube connect the hared tube,it is easy appear dead angle,and liquid or gas leakage problem.Easy structure,Easy maked.

2.Edge is no burrfree,it is ability to prevent the tube damaged

3.By a efficiently hydrogen relief treatment,long-term use needn't to worry fracture and other problems

Surface: zinc plated Packaging

4.Accord with DIN3017 Standard.By 48 hours salt and fog test,it has a good corrosion resistance

5.By our last 48 hours elastic test,to insure a high strength mechanical properties.

6.Easy to fix.

Working Temp: -40 ℃ ~ 110 ℃

Size:3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2

Structure: Suspension Clamp and so on On-time shipment and pre-shipment product quality safeguards clamp is mainly used in automobiles,tractors, ships, gasoline engine, and so on each kind of mechanical

device for oil, gas, hydraulic hose connector, various types of

rubber tube interface must join parts fastening.

Detail: plywood case ,pallets or any other package as buyer's requirements

Delivery Detail: about 20-30days

- Q: How to measure the motor current with a multimeter?

- Measurement of direct current. The first black probe into "COM" hole. If the measured current is more than 200mA, will be the red pen into the "10A" Jack and the knob to direct "10A"; if the current measurement is less than 200mA, the red pen into the "200mA" Jack will knob to the appropriate range of DC within 200mA. When adjusted, it can be measured. String the multimeter into the circuit and keep it steady until you read it. If the display is "1.", then to increase the range; if the numerical left "-" appears, indicates that the current from flowing into the black pen multimeter.

- Q: How to detect electronic fishing gear?

- The other is a direct current clamp type measurement table (see Figure three), general electrician or electronics repair shop has the current clamp type table, the table in the DC gear, the range of current selection must input current electronic fishing device is greater than the measured gear.

- Q: The difference between digital multimeter and caliper type multimeter

- The principle of clamp meter is the use of electromagnetic induction principle, core wire clamp measurement will require the clamp meter of silicon steel lamination edges, then the wire clamp is equivalent to a coil current transformer, belonging to a current through the coil, when will dinner two coil clamp type ammeter inside induction two current, current in the wire clamp type ammeter dial can read the measurements.

- Q: What's the difference between a caliper meter and an ordinary multimeter?

- The ordinary multimeter can measure current, but the table access circuit, which belongs to the "lossy" detection and tandem process category, too much trouble, it is a waste of time; the hardcore repairman will do two special pens, but only reduce the complexity of access, or inconvenient.

- Q: How to measure the current and voltage clamp meter?

- (1) in the measuring line, to clamp meter data of zero, to prevent errors in subsequent measurement.(2) after determining the voltage of the line to be measured, select the appropriate range.

- Q: How to test the current on a motor?

- String into the pointer ammeter to see the impact value of the pointer (not very accurate)

- Q: How much power does a computer power 297W require?

- Genuine 300W not 2 floor is a look at the white.At the very least, the 400W is rated and is slightly above grade!

- Q: What is the connection between the distribution box and the bridge?

- The ground wire is at least 4 square cord, 4 square wire rated operating current of about 30A, since it has been burned, indicating that the current has doubled, and the current duration is longer.

- Q: What is the cause of the tripping of the two phase motor?

- Leakage of electricity, turn on the motor - coil some varnish, and then dry, will solve the problem. If you do not have this process, let the maintenance master help you solve.

- Q: A multimeter what brand is good

- TLHG-9902 digital DC micro meter is mainly used to measure DC leakage current or conductance current value, high accuracy, wide range, intuitive reading, digital display, easy to use. Shock resistance, excess automatic protection, polarity display.Product characteristicsA table clock box shaped shell is made of stainless steel, the measurement results in the front display instrument, the instrument is arranged on the upper part of the socket and equipped with shielding cable as output measurement. The lower part of the instrument is provided with a joint as the measuring input. The battery is arranged in the box and is provided with a power switch.

Send your message to us

heavy duty stainless steel pipe clamp

- Loading Port:

- Qingdao

- Payment Terms:

- TT LC

- Min Order Qty:

- 100 pcs pc

- Supply Capability:

- 300000pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords