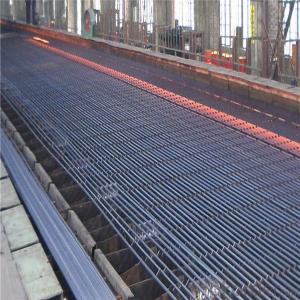

Steel Rebars prices per ton for building construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Common rebar is made of unfinished steel, making it susceptible to rusting. As rust takes up greater volume

than the iron or steel from which it was formed, it causes severe internal pressure on the surrounding concrete,

leading to cracking, spalling, and ultimately, structural failure. This is a particular problem where the concrete is

exposed to salt water, as in bridges built in areas where salt is applied to roadways in winter, or in marine applications.

Epoxy-coated rebar or stainless steel rebar may be employed in these situations at greater initial expense, but significantly

lower expense over the service life of the project. Fiber-reinforced polymer rebar is now also being used in high-corrosion environments

Our Advantage: High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: How do steel rebars contribute to the overall sustainability of a project?

- Steel rebars contribute to the overall sustainability of a project in several ways. Firstly, steel rebars are highly durable and have a long lifespan, which means they do not need to be replaced frequently. This reduces the consumption of resources and minimizes the need for new material production, thereby decreasing the environmental impact of the project. Additionally, steel rebars are fully recyclable. At the end of their life cycle, they can be easily collected, melted down, and repurposed into new steel products. This recycling process significantly reduces the demand for raw materials, conserves energy, and decreases the amount of waste going to landfills. Furthermore, steel rebars provide structural strength and enhance the overall safety and resilience of the project. By reinforcing concrete structures, steel rebars help increase their load-bearing capacity and resistance to external forces, such as earthquakes or extreme weather events. This ensures the longevity and stability of the project, reducing the need for repairs or reconstruction in the future. Lastly, the use of steel rebars in construction projects often results in shorter construction time and lower maintenance costs. The ease of handling and installing steel rebars allows for efficient construction processes, leading to reduced energy consumption and lower greenhouse gas emissions. Moreover, the durability and low maintenance requirements of steel rebars minimize the need for ongoing repairs and replacements, resulting in cost savings over the project's lifespan. In conclusion, steel rebars contribute to the overall sustainability of a project by being durable, recyclable, and enhancing structural strength and safety. Their use reduces resource consumption, waste generation, and energy consumption, while also providing long-term cost savings. Incorporating steel rebars in construction projects is a sustainable choice that promotes environmental conservation, economic efficiency, and social resilience.

- Q: Can steel rebars be used in underground construction projects?

- Yes, steel rebars can be used in underground construction projects. Steel rebars are commonly used for reinforcement in concrete structures, including those built underground. They provide strength and durability to the construction, making them suitable for various underground applications such as tunnels, basements, and underground parking structures.

- Q: Can steel rebars be welded or spliced together?

- Steel rebars can be welded or spliced together. Welding is a commonly utilized technique in joining steel rebars. It involves heating the rebars to a high temperature and utilizing a welding electrode to melt the steel, forming a sturdy bond. Welding is commonly employed in construction projects that require continuous reinforcement. Alternatively, splicing involves connecting two rebars using mechanical connectors or couplers. These connectors are designed to offer a dependable and robust connection between the rebars. Splicing is frequently used when extending rebars or joining different rebars. Both welding and splicing methods possess their own advantages and disadvantages. Welding provides continuous reinforcement and establishes a strong bond between the rebars; however, it necessitates skilled labor and can be time-consuming. On the other hand, splicing is a quicker and easier process, but it may slightly reduce the overall strength of the reinforcement. It is crucial to note that the utilization of welding or splicing for steel rebars must conform to the appropriate codes and standards, as well as receive approval from the structural engineer or responsible authority.

- Q: What is the minimum cover required for steel rebars in concrete?

- The minimum cover required for steel rebars in concrete typically depends on the specific project's design and local building codes. However, a general guideline is that the minimum cover should be at least 1.5 inches (38 mm) for rebars in exposed conditions and 3/4 inch (19 mm) for rebars in non-exposed conditions. It is essential to consult the project's structural engineer or refer to the local building codes for the precise minimum cover requirements.

- Q: Can steel rebars be used in high-strength concrete?

- Yes, steel rebars can be used in high-strength concrete. In fact, steel rebars are commonly used to reinforce concrete structures, regardless of the concrete strength. High-strength concrete refers to concrete that has a compressive strength significantly higher than conventional concrete. It typically has a compressive strength of 6,000 psi (pounds per square inch) or more. Steel rebars are essential in high-strength concrete to provide the necessary tensile strength. While concrete has excellent compressive strength, it is relatively weak in tension. By incorporating steel rebars into the concrete, the composite material becomes stronger and more durable. The rebars act as reinforcement, resisting the tensile forces and preventing cracks or failure in the structure. However, it is important to note that the selection of the appropriate steel rebar for high-strength concrete is crucial. The rebars used should have sufficient strength and ductility to withstand the higher stresses and strains associated with high-strength concrete. Additionally, proper placement, spacing, and anchorage of the rebars are essential to ensure effective reinforcement and optimal performance of the concrete structure. In summary, steel rebars can definitely be used in high-strength concrete to enhance its tensile strength and overall structural integrity.

- Q: Can steel rebars be used in sports arena construction?

- Yes, steel rebars can be used in sports arena construction. Steel rebars are commonly used in the construction industry for their strength, durability, and ability to reinforce concrete structures. In sports arena construction, steel rebars are often utilized to reinforce the concrete foundations, beams, columns, and other structural elements of the building to ensure its stability and withstand heavy loads.

- Q: What is the role of lap splicing in steel rebars?

- The role of lap splicing in steel rebars is to provide continuity and strength to the reinforcement system. It involves overlapping two rebars and connecting them securely to transfer loads effectively in reinforced concrete structures. Lap splicing is essential for maintaining the structural integrity and distributing the tensile forces evenly throughout the reinforced concrete elements, ensuring their durability and safety.

- Q: Can steel rebars be used in precast concrete elements?

- Yes, steel rebars can be used in precast concrete elements. Rebars provide reinforcement to the concrete, increasing its strength and durability. They are commonly used in precast concrete elements to ensure structural integrity and enhance load-bearing capacity.

- Q: What are the guidelines for protecting steel rebars during concrete pouring?

- Protecting steel rebars during concrete pouring is crucial to ensure the structural integrity and longevity of reinforced concrete structures. The following guidelines should be followed: 1. Clean the rebars: Before pouring concrete, it is essential to clean the rebars thoroughly to remove any dirt, rust, or other contaminants. This can be done using wire brushes or power tools to achieve a clean and smooth surface. 2. Rust prevention: Apply an appropriate rust inhibitor or anti-corrosion coating to the rebars after cleaning. This will help protect the steel from corrosion caused by moisture or chemicals present in the concrete. 3. Proper placement: Ensure that the rebars are placed at the correct depth and spacing as specified in the structural drawings or design codes. This will provide the necessary reinforcement and structural strength to the concrete. 4. Support and alignment: Use proper supports, such as chairs or spacer blocks, to maintain the correct alignment and position of the rebars during the concrete pour. This will prevent any displacement or movement of the rebars. 5. Tie the rebars securely: Use steel wire or rebar ties to secure the rebars together at intersections and overlap areas. This will ensure that the rebars remain in place and maintain the desired structural configuration. 6. Avoid contact with the ground: Prevent the rebars from coming into direct contact with the ground during the pouring process. This can be achieved by using plastic or concrete chairs to elevate the rebars above the ground surface. 7. Use plastic caps: Cover the exposed ends of the rebars with plastic caps to protect them from moisture, dirt, or other contaminants while the concrete cures. 8. Adequate concrete cover: Ensure that the rebars are adequately covered by the concrete. The concrete cover is the distance between the outer surface of the rebars and the nearest outer surface of the concrete. This cover protects the rebars from external elements and prevents corrosion. 9. Monitor concrete placement: During concrete pouring, take precautions to avoid displacing or damaging the rebars. This can be achieved by using proper pouring techniques, such as using a tremie pipe or a concrete pump, to minimize the impact on the rebars. 10. Curing and protection: After the concrete is poured, it is crucial to properly cure and protect it. This includes covering the concrete with wet burlap or plastic sheeting to maintain moisture levels and prevent premature drying, cracking, or shrinkage. Adequate curing will also help in protecting the rebars from corrosion. By following these guidelines, the rebars can be effectively protected during concrete pouring, ensuring the durability and strength of the reinforced concrete structure.

- Q: How much is the minus difference per ton of thread steel?

- In use, some mechanical strength, bending deformation property and welding performance are required. The raw steel billet for the production of threaded steel is carbon structural steel or low alloy structural steel which is treated by calm melting, and the finished steel bar is delivered in hot rolling forming, normalizing or hot rolling state. The grade of thread steel is composed of the minimum value of the yield point of HRB and brand.

Send your message to us

Steel Rebars prices per ton for building construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords