Hrb400 Steel Rebar Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hrb400 Steel Rebar

Description of Hrb400 Steel Rebar

1, Diameter: 5.5mm-10mm Hrb400 Steel Rebar

10m- 40mm Hrb400 Steel Rebar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Hrb400 Steel Rebar

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

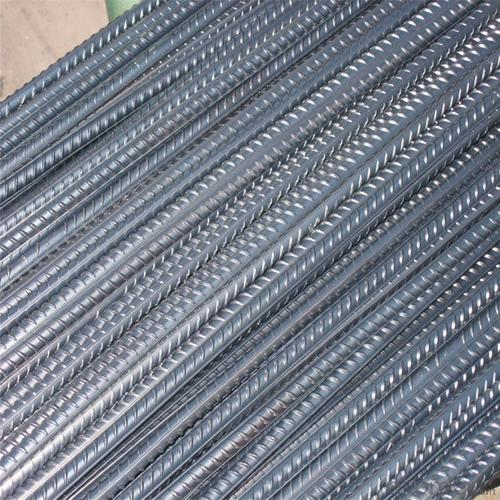

Products Show of Hrb400 Steel Rebar

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Can special steel be used in the production of gears?

- Yes, special steel can be used in the production of gears. Special steel, such as alloy steel or tool steel, is often preferred in gear manufacturing due to its high strength, wear resistance, and ability to withstand heavy loads and high temperatures. This steel type ensures gears have the necessary durability and performance required for various applications.

- Q: What are the main applications of special steel in the medical implants?

- Special steel is widely used in medical implants due to its unique properties and benefits. The main applications of special steel in medical implants include orthopedic implants such as hip and knee replacements, dental implants, cardiovascular devices like stents and pacemakers, and surgical instruments. The high strength, corrosion resistance, biocompatibility, and ability to be sterilized make special steel an ideal material for these applications, providing long-lasting and reliable solutions for patients in need of medical implants.

- Q: How does special steel contribute to the tool manufacturing industry?

- Special steel plays a crucial role in the tool manufacturing industry by providing enhanced strength, durability, and wear resistance to tools. This type of steel is specifically designed to withstand extreme conditions and heavy usage, allowing tools to perform efficiently and last longer. With its unique properties, special steel enables the production of high-quality, precision tools that can handle demanding tasks in various industries, ultimately enhancing productivity and ensuring safety for workers.

- Q: What is the impact of impurities on the machinability of special steel?

- Impurities can have a significant impact on the machinability of special steel. These impurities can cause variations in the material's hardness, toughness, and other mechanical properties, making it more difficult to machine. They can also lead to increased tool wear and reduced cutting speeds, resulting in lower productivity and increased production costs. Therefore, it is crucial to minimize impurities during the manufacturing process to ensure optimal machinability of special steel.

- Q: How does special steel contribute to the manufacturing of industrial machinery?

- Special steel plays a crucial role in the manufacturing of industrial machinery by providing superior strength, durability, and resistance to extreme conditions. It allows for the construction of components that can withstand heavy loads, high temperatures, and corrosive environments, ensuring the reliability and longevity of the machinery. Additionally, special steel's unique properties enable the production of precise and intricate parts, enhancing the overall performance and efficiency of industrial machinery.

- Q: How does special steel contribute to the infrastructure sector?

- Special steel plays a crucial role in the infrastructure sector by contributing to the construction and maintenance of various structures. It is widely used in the sector due to its exceptional strength, durability, and resistance to wear and tear. One of the key areas where special steel makes a significant contribution is in the construction of bridges. Bridges are subjected to heavy loads, extreme weather conditions, and constant vibrations, making the use of high-quality steel essential. Special steel, such as high-strength low-alloy (HSLA) steel or weathering steel, provides the necessary strength and corrosion resistance to ensure the longevity and safety of bridges. Moreover, special steel is also extensively utilized in the construction of high-rise buildings and skyscrapers. These structures require steel that can withstand tremendous loads and provide stability. Special steel grades, such as high-strength steel or structural steel, offer the necessary strength-to-weight ratio, allowing architects and engineers to design taller and more robust structures. In addition to its usage in construction, special steel also contributes to the infrastructure sector through its application in manufacturing equipment and machinery used for construction and maintenance activities. It is used in the production of heavy machinery, cranes, excavators, and other construction equipment, providing the necessary strength and reliability to withstand the demanding conditions of the sector. Furthermore, special steel is crucial in the development of transportation infrastructure. It is used in the manufacturing of railway tracks, ensuring their durability and resistance to wear caused by the continuous movement of trains. Additionally, it is used in the production of reinforcing bars for concrete in road construction, providing the necessary strength and stability to withstand heavy traffic loads. Overall, special steel's exceptional properties make it an indispensable material in the infrastructure sector. Its strength, durability, and resistance to corrosion contribute to the construction and maintenance of various structures, ensuring their longevity, safety, and reliability.

- Q: How is special steel used in the packaging industry?

- Special steel is used in the packaging industry for a variety of applications such as manufacturing durable and corrosion-resistant containers, packaging machinery, and tools used in the packaging process. It provides strength, reliability, and longevity, ensuring the safety and protection of products during storage and transportation.

- Q: How does special steel contribute to the manufacturing of defense equipment?

- Special steel plays a crucial role in the manufacturing of defense equipment due to its exceptional properties. It provides enhanced strength, durability, and resistance to extreme conditions, making it ideal for critical components such as armor plates, missile casings, or aircraft parts. Special steel's ability to withstand high temperatures, impacts, and corrosion ensures the reliability and longevity of defense equipment, ultimately enhancing the safety and effectiveness of military operations.

- Q: How does special steel perform in construction applications?

- Special steel performs exceptionally well in construction applications due to its superior strength, durability, and resistance to corrosion. It allows for the creation of structurally sound and long-lasting buildings, bridges, and other infrastructure. Additionally, its versatility and ability to be fabricated into various shapes and sizes make it highly suitable for a wide range of construction projects.

- Q: What are the applications of special steel in the oil and gas supply chain?

- Special steel has various applications in the oil and gas supply chain. It is commonly used in the construction of pipelines, drilling equipment, and offshore platforms. Special steel's high strength, corrosion resistance, and ability to withstand extreme temperatures make it ideal for these applications. Additionally, special steel is used in the manufacturing of valves, fittings, and other components that are crucial for the efficient and safe operation of the oil and gas supply chain.

Send your message to us

Hrb400 Steel Rebar Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords