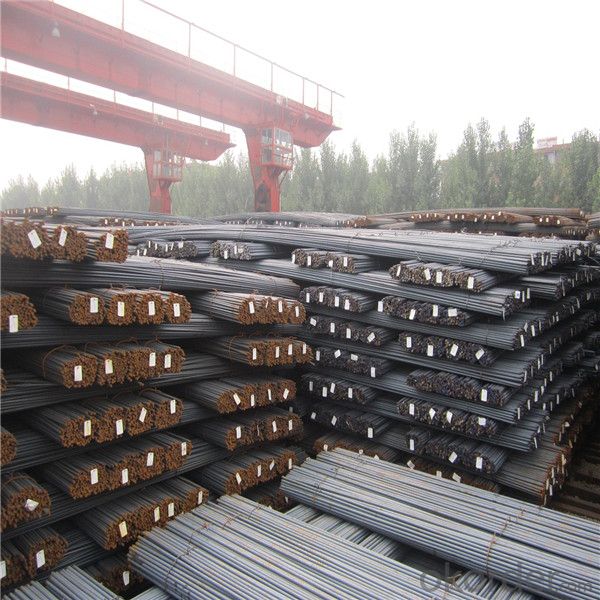

Rebar Steel Prices of China mill HRB400

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 19000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Rebar is common steel reinforcing bar, an important component of reinforced concrete and reinforced masonry structures.

It is usually formed from mild steel, and is given ridges for better frictional adhesion to the concrete.

Concrete is a material that is very strong in compression, but virtually without strength in tension. To compensate for this

imbalance in concrete's behavior, rebar is formed into it to carry the tensile loads.

.

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What is the weight of steel rebars per meter or foot?

- The weight of steel rebars per meter or foot can vary based on the size and type of rebar utilized. Standard steel rebars are typically accessible in different diameters, ranging from 6mm to 50mm. By multiplying the cross-sectional area of the rebar (measured in square meters or square feet) by the density of steel (approximately 7850 kilograms per cubic meter or 0.2836 pounds per cubic inch), one can ascertain the weight per meter or foot. To provide an example, let's examine a standard rebar with a diameter of 10mm. The cross-sectional area can be determined using the formula for the area of a circle (πr²), where r represents the radius of the rebar (5mm in this case). Assuming the unit of measurement is a meter, the cross-sectional area would equal π(0.01m)² = 0.000314 square meters. By multiplying this value by the density of steel, we arrive at 0.000314m² * 7850kg/m³ = 2.464 kilograms per meter. Similarly, if we were to calculate the weight in pounds per foot, we would convert the density of steel to pounds per cubic foot (approximately 490 pounds per cubic foot) and multiply the cross-sectional area by this figure. It is important to note that weight may slightly vary depending on the specific steel grade employed. Therefore, it is advisable to consult the manufacturer's specifications or a reliable reference for precise weight calculations.

- Q: How are steel rebars connected to each other?

- Steel rebars are typically connected to each other using various methods such as overlapping, welding, or using mechanical connectors like couplers or threaded bars.

- Q: Can steel rebars be used in thin concrete elements?

- Yes, steel rebars can be used in thin concrete elements. However, it is important to ensure that the rebars are properly spaced and adequately covered with concrete to provide sufficient strength and durability to the structure. Additionally, the design and placement of rebars should be carried out in accordance with the specific requirements and recommendations of the construction codes and standards.

- Q: What are the considerations for using epoxy-coated steel rebars?

- When it comes to epoxy-coated steel rebars, there are several important factors that need to be taken into account. These factors include corrosion resistance, durability, cost-effectiveness, and construction requirements. One of the main factors to consider is the corrosion resistance provided by epoxy-coated steel rebars. The epoxy coating acts as a protective barrier against moisture, chemicals, and other corrosive elements commonly found in concrete structures. This coating significantly reduces the risk of corrosion, thereby increasing the lifespan of the rebar and the overall durability of the reinforced concrete. Durability is another crucial consideration. Epoxy-coated steel rebars are specifically designed to withstand harsh environmental conditions, including exposure to chloride ions that are known to accelerate corrosion in traditional black steel rebars. This enhanced durability ensures the structural integrity of the building over a longer period, reducing the need for expensive repairs or replacements. Cost-effectiveness is also an important factor to think about. Although epoxy-coated steel rebars may have a higher initial cost compared to black steel rebars, their long-term cost-effectiveness is evident. The reduced risk of corrosion and subsequent maintenance or repair expenses can result in significant savings over the lifespan of a structure. Additionally, the extended lifespan of the rebar can contribute to lower life-cycle costs. Construction requirements must also be considered when using epoxy-coated steel rebars. The application of the epoxy coating requires careful handling and storage to prevent damage or contamination. Special precautions must be taken during transportation, storage, and installation to maintain the integrity of the coating. Contractors must also undergo training and possess experience in working with epoxy-coated steel rebars to ensure proper installation and adherence to industry standards. In conclusion, the considerations for using epoxy-coated steel rebars encompass corrosion resistance, durability, cost-effectiveness, and specific construction requirements. Despite the higher initial cost and the need for additional care during handling and installation, the long-term benefits of increased corrosion resistance and durability make them a favorable choice for reinforced concrete structures.

- Q: Is thread steel rod or wire?

- 10mm below can also be transferred to the wire, 10mm or more to the bar. Wire and rod are attributed to the bar, so there is no distinction between strictly.

- Q: How do steel rebars impact the overall construction timeline?

- Steel rebars play a crucial role in the overall construction timeline as they significantly impact the speed and efficiency of the construction process. The use of steel rebars helps in reinforcing the concrete structures, providing strength, durability, and resistance to the overall construction project. Firstly, steel rebars enable faster construction by reducing the curing time of concrete. When embedded within the concrete, rebars help to distribute the load evenly, making the structure stronger and allowing for quicker construction. This is especially important in high-rise buildings or large-scale projects where time is of the essence. Moreover, steel rebars enhance the structural integrity of the construction, ensuring that it can withstand various forces such as earthquakes, wind, and heavy loads. By reinforcing the concrete, rebars prevent cracks and failures, enhancing the longevity and safety of the building. This reduces the need for costly repairs or renovations in the future, thereby saving time in the long run. Additionally, the use of steel rebars allows for flexibility in design and construction. With rebars, architects and engineers can create complex structures, such as curved or irregular shapes, without compromising on strength or stability. This versatility reduces the time required for design modifications and construction alterations, enabling a faster overall timeline. Furthermore, steel rebars are readily available in the market and are manufactured to meet specific industry standards. This ensures a consistent supply of high-quality materials, reducing delays caused by material shortages or quality issues. Contractors can easily procure rebars, allowing for a smooth workflow and timely completion of the construction project. In conclusion, steel rebars have a significant impact on the overall construction timeline. They accelerate the construction process, increase the structural integrity, allow for design flexibility, and ensure a consistent supply of materials. By incorporating steel rebars into construction projects, contractors can save time, reduce potential setbacks, and deliver projects within the desired timeframe.

- Q: Can steel rebars be used in structures with limited construction regulations?

- Steel rebars can be used in structures with limited construction regulations, but it is important to note that the safety and structural integrity of the building may be compromised without proper regulations. Steel rebars are commonly used as reinforcement in concrete structures to provide strength and stability. However, the use of rebars alone does not guarantee the safety of a structure. Construction regulations exist to ensure that buildings are designed and constructed to withstand various forces and loads, such as wind, earthquakes, and live loads. These regulations also cover aspects such as fire safety, electrical systems, and accessibility. Without these regulations, there is a higher risk of structural failure or other safety issues. Using steel rebars in structures without proper construction regulations may result in buildings that are not adequately designed or constructed to withstand these forces and loads. This can lead to structural failure, collapse, or other hazards. It is therefore advisable to adhere to local construction codes and regulations to ensure the safety and longevity of any structure.

- Q: How do steel rebars affect the overall fire resistance of concrete structures?

- Steel rebars can significantly improve the fire resistance of concrete structures. The high thermal conductivity of steel helps in dissipating heat away from the concrete, preventing rapid temperature rise and structural failure. Additionally, the presence of rebars enhances the load-bearing capacity of the structure during a fire, enabling it to withstand the intense heat for a longer duration before collapsing.

- Q: When did the 1305 rebar contract become a major contract?

- The thread has 3 different contracts, which have been completed. They are continuous thread (1211 contract) and thread four (1303 contract). 1305 into the thread, even Sihui next month, into the thread, it will continue until April 13 years.

- Q: What is the impact of steel rebars on the overall carbon footprint of a building?

- The overall carbon footprint of a building is significantly influenced by the presence of steel rebars. This is because the production of steel involves the consumption of high amounts of energy and the release of substantial greenhouse gas emissions, particularly carbon dioxide. The carbon footprint of a building is further affected by activities such as the extraction and processing of iron ore, as well as the manufacturing and transportation of steel rebars. The extent to which steel rebars are used in a building also plays a role in its carbon footprint. The more steel rebars that are utilized, the higher the carbon footprint will be. The quantity of steel rebars required is determined by factors such as the size and complexity of the structure, as well as specific design requirements. However, it is worth noting that steel rebars are an essential component of reinforced concrete, which is widely used in construction due to its strength and durability. Reinforced concrete ensures the structural integrity and longevity of a building, consequently contributing to its safety. While steel rebars contribute to the building's carbon footprint, they also play a critical role in constructing secure and resilient structures. To mitigate the carbon footprint associated with steel rebars, several strategies can be employed. One approach is to utilize recycled steel rebars, which significantly reduces the energy consumption and emissions associated with steel production. Additionally, optimizing the design and construction process can help minimize the overall amount of steel required, thereby reducing the carbon footprint. Furthermore, alternative materials such as fiber-reinforced polymers (FRPs) are being developed as substitutes for steel rebars. FRPs have lower carbon footprints since they are made from materials like fiberglass or carbon fiber, which have lower emissions during production. However, the use of FRPs is still limited, and further research and development are needed to enhance their viability as a mainstream alternative. In conclusion, the presence of steel rebars has a significant impact on the carbon footprint of a building due to the energy-intensive production process and emissions associated with their extraction, manufacturing, and transportation. Nevertheless, their crucial role in providing structural integrity and durability should not be overlooked. Efforts to reduce the carbon footprint of steel rebars include the use of recycled materials, the optimization of designs, and the exploration of alternative materials like FRPs. Ultimately, a comprehensive approach that considers both the environmental impact and the structural requirements of a building is necessary to minimize the carbon footprint associated with steel rebars.

Send your message to us

Rebar Steel Prices of China mill HRB400

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 19000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords