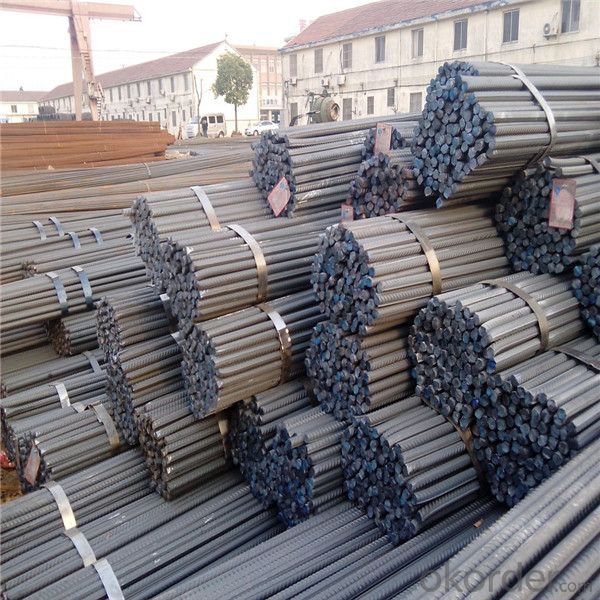

Iron rods of 6-25MM HRB400 HRB500 for building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Deformed Steel bar is a common steel reinforcing bar, used in reinforced concrete and reinforced masonry structures.

It is formed from mild steel, and is given ribs for better frictional adhesion to the concrete. The Deformed Steel bar is an

iron rod , a weldable plain reinforcing steel bar, and can be used as well for steel meshes.

To prevent workers from accidentally impaling themselves, the protruding ends of steel rebar are often bent over or covered

with special plastic "mushroom" caps.

Our Advantage: High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What are the guidelines for the proper lap splicing of steel rebars?

- The guidelines for the proper lap splicing of steel rebars include ensuring that the rebars are clean and free from rust, dirt, or any other contaminants. The spliced rebars should have appropriate overlapping lengths as specified by the design engineer. The lap splice should be made using mechanical splicing methods or approved splice connectors to ensure proper load transfer. The spliced rebars should be securely positioned and aligned to maintain the required concrete cover. It is essential to follow the specific codes and standards set by the construction industry for lap splicing to ensure the structural integrity and safety of the reinforced concrete structure.

- Q: What are steel rebars?

- Steel rebars, also known as reinforcement bars, are steel bars or rods that are used to strengthen and reinforce concrete structures. They are typically embedded within the concrete to provide tensile strength, preventing cracks and enhancing the structural integrity of buildings, bridges, and other infrastructure projects.

- Q: What are the common misconceptions about steel rebars?

- One common misconception about steel rebars is that they are only used in large construction projects. While it is true that rebars are commonly used in the construction of large buildings, bridges, and other infrastructure, they are also utilized in smaller projects such as residential homes, retaining walls, and even garden structures. Rebars provide strength and reinforcement to concrete structures, ensuring their durability and longevity. Another misconception is that all rebars are the same. In reality, there are various types of rebars available, each with specific characteristics and purposes. Common types include carbon steel rebars, epoxy-coated rebars, stainless steel rebars, and galvanized rebars. These different types are used depending on factors like the environment, exposure to corrosive elements, and specific project requirements. Some people also believe that rebars do not require proper placement or spacing within the concrete structure. However, incorrect placement or inadequate spacing of rebars can lead to structural weaknesses, compromising the integrity of the concrete. It is crucial to follow engineering specifications and guidelines to ensure the rebars are correctly positioned and spaced to provide optimal reinforcement. Another misconception is that steel rebars rust easily. While it is true that steel can corrode when exposed to moisture and oxygen, proper construction practices can significantly minimize this risk. For instance, the use of epoxy-coated or galvanized rebars provides an additional layer of protection against corrosion. Additionally, proper concrete cover and application of protective coatings can help prevent moisture penetration and extend the lifespan of the rebars. Lastly, some people believe that steel rebars are expensive and not cost-effective. While it is true that steel rebars can add to the overall cost of a construction project, they are a necessary investment for ensuring structural integrity and safety. The cost of repairing or replacing a structure due to inadequate reinforcement far outweighs the initial investment in quality rebars. Moreover, the use of rebars can reduce the need for excessive concrete, resulting in cost savings in material and construction time. In conclusion, it is important to dispel common misconceptions about steel rebars. They are not limited to large construction projects, come in different types, require proper placement and spacing, can be protected against corrosion, and are a cost-effective investment for ensuring the durability and safety of concrete structures.

- Q: How are steel rebars protected during storage and transportation?

- Steel rebars are typically protected during storage and transportation through the application of a protective coating, such as epoxy or zinc, which helps prevent corrosion. Additionally, they may be stored in covered and dry areas to minimize exposure to moisture and other environmental elements.

- Q: Are steel rebars available in different shapes and profiles?

- Yes, steel rebars are available in various shapes and profiles to suit different construction needs.

- Q: Can steel rebars be used in the construction of shopping malls and commercial buildings?

- Yes, steel rebars can be used in the construction of shopping malls and commercial buildings. Steel rebars provide strength, durability, and reinforcement to the concrete structures, ensuring the safety and stability of the buildings. They are commonly used in the construction industry for their ability to withstand heavy loads and resist bending or breaking. Additionally, steel rebars are versatile and can be easily molded into different shapes, making them suitable for various structural designs in shopping malls and commercial buildings.

- Q: Can steel rebars be used in pre-stressed or post-tensioned concrete structures?

- Yes, steel rebars can be used in pre-stressed or post-tensioned concrete structures. In pre-stressed concrete, the rebars are tensioned before the concrete is poured, creating compression within the concrete to counteract external loads. In post-tensioned concrete, the rebars are tensioned after the concrete has set, providing additional strength and reducing cracking. Steel rebars are commonly used in both types of structures due to their high tensile strength and ability to withstand the stress induced by the pre-stressing or post-tensioning process.

- Q: What is the process of joining steel rebars together?

- The process of joining steel rebars together is commonly done through methods such as overlap splicing, mechanical splicing, and welding. In overlap splicing, two rebars are overlapped and tied together using wire or steel straps. Mechanical splicing involves using couplers or threaded connectors to join rebars together. Welding, on the other hand, involves melting the ends of two rebars and fusing them together using heat. Each method has its own advantages and considerations, depending on factors like the structural requirements and project specifications.

- Q: What are the different methods of joining steel rebars?

- There is a range of methods available for joining steel rebars, each with its own set of advantages and disadvantages. Here, we present the most common techniques: 1. Lap Splicing: The most widely used method for joining rebars is lap splicing. It entails overlapping two rebars and securing them together with wire or metal ties. This approach is cost-effective and straightforward, but it necessitates longer lap lengths to achieve the required strength. 2. Mechanical Splicing: Mechanical splicing involves connecting rebars using mechanical couplers or splices. These couplers are specifically designed to establish a strong and dependable connection between the rebars. Mechanical splicing enables quicker installation and reduces the need for lengthy overlaps. However, it may be more costly compared to lap splicing. 3. Welding: Another option for joining steel rebars is welding. This process involves heating the rebars and fusing them together using electric arcs or gas flames. Welding creates a robust and permanent connection, but it requires skilled labor and specialized equipment. It is commonly employed in precast concrete applications. 4. Bolted Connections: Bolted connections utilize bolts and nuts to join the rebars. This method offers a flexible and adjustable connection, making it suitable for certain applications. However, bolted connections necessitate additional hardware and may not be as strong as other methods. 5. Adhesive Bonding: Adhesive bonding involves using epoxy or other adhesives to join rebars. The adhesive is applied to the rebars, and they are pressed together until the adhesive cures and forms a strong bond. Adhesive bonding provides a clean and aesthetically pleasing finish, but it may not offer the same level of strength as other methods and is more suitable for non-structural applications. It is essential to consider factors such as specific project requirements, structural design, and construction techniques when selecting a joining method. Consulting with structural engineers and adhering to industry standards and codes is crucial to ensure the appropriate selection and implementation of the joining method for steel rebars.

- Q: What are the cost implications of using steel rebars in construction?

- The cost implications of using steel rebars in construction can vary depending on several factors. Steel rebars are generally more expensive than alternative materials such as concrete, but they offer several advantages that can offset the higher upfront cost. Using steel rebars can lead to quicker and easier construction processes, as they are readily available and can be easily installed. This can result in reduced labor costs and shorter construction timelines, which can be beneficial for overall project costs. Moreover, steel rebars offer excellent strength and durability, making them a reliable choice for reinforcing concrete structures. They can enhance the structural integrity of buildings, bridges, and other infrastructure, potentially reducing the need for costly repairs or maintenance in the long run. However, it is important to consider the potential costs associated with corrosion protection for steel rebars, as they are prone to rusting when exposed to moisture or harsh environments. Implementing appropriate measures, such as proper coating or using stainless steel rebars, can help mitigate these costs. Overall, while steel rebars may incur higher initial expenses, their numerous advantages in terms of strength, durability, and construction efficiency often make them a cost-effective choice in the long term.

Send your message to us

Iron rods of 6-25MM HRB400 HRB500 for building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords