Steel Reinforcing Bar 5.5mm-32mm for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Reinforcing Bar 5.5mm-32mm for Building

Description for Reinforcing Bar:

| Reinforcing steel bars, rebar, Deformed steel bars | |||

| Size: | 8mm-32mm | Steel Grade: | HRB335, HRB400, HRB500, A615 Gr40, Gr60,BS4449 G460B, G500B JIS SD390, SD490, KS SD40, SD50 |

| Length: | 6m-12m | MOQ each size: | 200MT. |

| Loading port: | Tianjin or any other port china. | Packing: | in bundle. |

Payment term | LC , TT | Application: | Building, bridge , road or project construction |

Data for Reinforcing Bar:

HRB400 | Chemical Composition(%) | C | Mn | Si | P | S |

| 0.25max | 1.60max | 0.80max | 0.045max | 0.045max | ||

Mechanical Property | Yield Strength | Tensile Strenth | Elongation | |||

| 400Mpa min | 540Mpa min | 16% | ||||

HRB500 | Chemical Composition(%)

| C | Mn | Si | P | S |

| 0.25max | 1.60max | 0.80max | 0.045max | 0.045max | ||

| Mechanical Property | Yield Strength | Tensile Strength | Elongation | |||

| 500Mpa min | 630Mpa min | 15% | ||||

| HRB335 | Chemical Composition (%) | C | Mn | Si | P | S |

| 0.25max | 1.60max | 0.80max | 0.045max | 0.040max | ||

Mechanical Property | Yield Strength | Tensile strength | Elongation | |||

| 335Mpa min | 455Mpa min | 17% | ||||

Main Structure for Reinforcing Bar

Standard: AISI, ASTM, BS, DIN, GB, JIS, GOST

Grade: hrb335 hrb400 hrb500

Diameter: 5.5mm-32mm

Length: 6m-12m

Place of Origin: China (Mainland)

Model Number: 5.5mm-32mm

Application: contruction for project and building

steel reinforcing bar size: 5.5mm-32mm

steel reinforcing bar steel grade: hrb400 hrb500 hrb335 hpb300 q195

steel reinforcing bar length: 6mm-12mm

reinforcing bar MOQ:: 300MT for each size

FAQ:

Q: How’s your service?

A:1. Offer customers 24/7 service, whenever you need us, we are always here for you.

2. Immediate response. Your any inquiry will be replied within 24 hours.

3. Support small order quantity, for the first time cooperation customers, we can send you less quantity for trial order.

4. Support third party inspection company to inspect and check the quality and quantity before delivery.

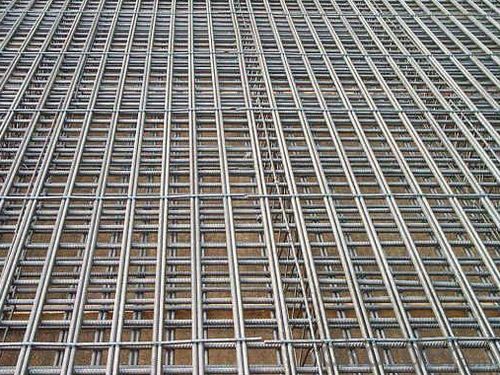

Picture:

- Q: How are steel rebars protected from moisture during storage?

- Steel rebars are protected from moisture during storage by applying a protective coating, such as anti-corrosion paint or epoxy, or by covering them with waterproof materials like plastic sheets or tarps. Additionally, storing rebars in a dry and well-ventilated area can help prevent moisture buildup.

- Q: What is the purpose of ribbing on a steel rebar?

- The purpose of ribbing on a steel rebar is to enhance the bond between the rebar and the surrounding concrete. The ribs, which are raised deformations along the length of the rebar, create a larger surface area for the concrete to grip onto. This increased surface area improves the mechanical interlock between the rebar and concrete, resulting in better load transfer and enhanced structural integrity. The ribbing also helps to prevent slippage or movement of the rebar within the concrete, ensuring that the reinforcement remains in its intended position, even under heavy loads or seismic activity. Overall, the ribbing on a steel rebar plays a crucial role in improving the performance and durability of reinforced concrete structures.

- Q: Can steel rebars be used in temporary structures?

- Yes, steel rebars can be used in temporary structures. Steel rebars provide structural reinforcement and can be used to strengthen concrete during construction. They can be easily installed and removed, making them suitable for temporary structures that require stability and durability.

- Q: What are the advantages of using epoxy-coated steel rebars?

- One of the main advantages of using epoxy-coated steel rebars is their superior corrosion resistance. The epoxy coating acts as a protective barrier, preventing moisture and chemicals from reaching the steel, thereby significantly reducing the risk of rusting and deterioration. This enhanced durability translates into longer service life and reduced maintenance costs. Additionally, the epoxy coating provides a smoother surface, improving bond strength with concrete and enhancing the overall structural integrity of reinforced concrete structures.

- Q: How do steel rebars affect the overall durability of concrete?

- Concrete structures benefit greatly from the presence of steel rebars, as they significantly contribute to their overall durability. Steel rebars enhance the strength of concrete and its ability to resist external forces and environmental conditions. One of the main functions of steel rebars is to provide tensile strength to concrete, which is naturally weak in resisting tension. Concrete is known for its excellent compressive strength but tends to crack under tension. By embedding steel rebars within the concrete, these cracks are effectively controlled and prevented from expanding, ultimately improving the durability of the structure. Steel rebars also increase the flexural strength of concrete, allowing it to withstand bending and deformations more effectively. This is particularly important in structures such as beams, columns, and slabs that experience significant loads and forces throughout their lifespan. Furthermore, steel rebars act as reinforcement in concrete, enhancing its resistance to external factors like earthquakes, wind, and impact loads. The presence of rebars helps distribute and dissipate these forces throughout the structure, reducing the risk of structural failure and increasing overall durability. Another crucial aspect is the prevention of corrosion in reinforced concrete structures. Steel rebars are typically coated with materials that protect them from corrosion caused by moisture and chemical reactions. This protective coating, combined with the alkaline environment of concrete, forms a barrier that significantly slows down the corrosion process, ultimately increasing the longevity and durability of the concrete structure. To conclude, steel rebars play a vital role in enhancing the overall durability of concrete structures. They provide necessary tensile strength, improve flexural strength, enhance resistance to external forces, and prevent corrosion. Incorporating steel rebars makes concrete more robust, long-lasting, and capable of withstanding various challenges, ensuring the longevity and safety of the structure.

- Q: What are the different types of steel rebars used in marine construction?

- The different types of steel rebars used in marine construction include epoxy-coated rebars, stainless steel rebars, and galvanized rebars. Epoxy-coated rebars are commonly used in marine environments due to their corrosion resistance properties. Stainless steel rebars are also used for their excellent corrosion resistance and strength. Galvanized rebars, which are coated with a layer of zinc, are another option for marine construction as they provide good protection against corrosion.

- Q: What are the different grades of steel rebars available?

- There are several different grades of steel rebars available in the market, each with specific characteristics and applications. The most commonly used grades include: 1. Grade 40: This is a low-strength rebar, suitable for general construction purposes where high tensile strength is not required. It is commonly used in residential buildings, sidewalks, and driveways. 2. Grade 60: This is a medium-strength rebar, offering higher tensile strength than Grade 40. It is widely used in commercial buildings, bridges, and infrastructure projects. Grade 60 rebar provides excellent reinforcement for heavy loads and structural stability. 3. Grade 75: This is a high-strength rebar, often used in challenging construction projects that require exceptional tensile strength. It is commonly utilized in high-rise buildings, parking garages, and industrial structures to ensure superior reinforcement and structural integrity. 4. Grade 80 and above: These are ultra-high-strength rebars designed for specialized applications where extreme load-bearing capacity is necessary. They are commonly used in heavy-duty infrastructure projects, such as dams, tunnels, and nuclear power plants, where the demand for strength is significantly higher. The choice of steel rebar grade depends on factors such as the specific construction project, load-bearing requirements, and environmental conditions. Engineers and architects evaluate these factors to determine the most suitable grade of steel rebar for a particular application, ensuring optimal performance and structural durability.

- Q: Can steel rebars be used in wastewater treatment plants?

- Yes, steel rebars can be used in wastewater treatment plants. Steel rebars are commonly used as reinforcement for concrete structures, including those found in wastewater treatment plants. The rebars provide strength and durability to the structures, ensuring they can withstand the harsh environments and corrosive nature of wastewater. However, it is important to select the appropriate grade of steel rebars that are resistant to corrosion caused by the chemicals present in wastewater.

- Q: Are steel rebars susceptible to corrosion?

- Yes, steel rebars are susceptible to corrosion. Corrosion is a natural process that occurs when steel is exposed to moisture, oxygen, and other environmental factors. When steel rebars are used in concrete structures, they are exposed to the elements and can come in contact with water or moisture, which can lead to the formation of rust. This rust can weaken the rebars and eventually compromise the structural integrity of the concrete. To prevent corrosion, various protective measures can be taken, such as applying a protective coating or using corrosion-resistant steel rebars. Regular maintenance and inspection of the concrete structures are also crucial to detect and address any signs of corrosion in a timely manner.

- Q: Can steel rebars be used in industrial flooring?

- Yes, steel rebars can be used in industrial flooring. Steel rebars are commonly used in concrete construction, including industrial flooring, due to their high tensile strength and durability. They are typically placed within the concrete to reinforce it and provide added strength to support heavy loads and resist cracking. The use of steel rebars in industrial flooring helps increase its load-bearing capacity and ensures the longevity and structural integrity of the floor. Additionally, steel rebars can be easily welded or connected to form a grid or mesh, which further enhances the strength and stability of the floor. Therefore, steel rebars are a suitable choice for industrial flooring applications.

Send your message to us

Steel Reinforcing Bar 5.5mm-32mm for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords