Stainless Steel and Galvanized Cleaning Ball Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

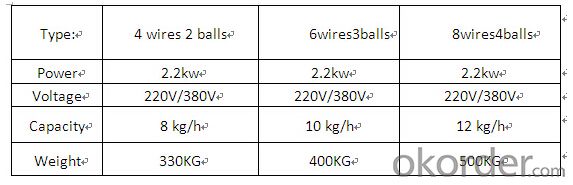

Easy operating ,low power consumption ,low malfunction rate , high output capacity.

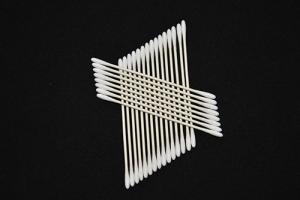

It can be used for manufacture of: Stainless Steel Scourer ,Galvanize Scourer ,Brass Scourer

Hot dipped Scourer.

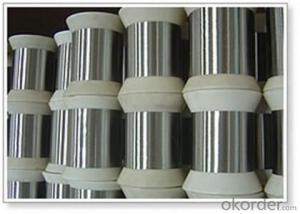

Raw materials:410 stainless steel wire ,galvanized wire etc.

Wire diameter:0.13-0.23mm etc

Output :round balls:4-5kg/h oblate balls:6-8kg/h

3.Advantages of wire mesh scourer making machine.

1)the kind of wire mesh scourer machine need not the cold water to cool.

2) not easy to broken wire,and the machine will be stop if any wire broken .

3)a skilled worker can operate 8 workbench

4)Also Auto-stop device , three steps in one machine , saving labor,high efficiency ,leading technology.

4.Main component: air compressor + water pump and fund.

Each machine is equped with one air comprosser.

5.Packaging detail:Wooden case of clean ball machine or plastic bag , can pack as client's request

6.Delivery time :Within7-15 working days after receiving your prepayment.

7..product photo

- Q: The equipment of our unit needs to be cleaned regularly, oil pollution is very much, every time manual washing efficiency is too low, what method can be solved quickly?

- Look at that oil and then choose the emulsifier To use the all-around emulsifier for oil and other oil Used for lubricating oil, mechanical oil and mine Oil, clutch oil, gear oil, brake oil, engine oil, ink, demoulding oil, compressor oil, refrigeration oil, vacuum pump oil, the internal combustion engine oil (1: diesel engine oil. 2: gasoline engine oil. 3: ship oil), oil bearing, guide Rail oil, hydraulic oil, hydraulic oil, metal processing oil dynamic tools, electrical insulating oil, oil, heat conduction oil, rust-proof oil, special occasions, oil, turbine oil, quenching oil, fuel oil, oil have oil selection and other occasions Engine oil emulsifier, no oil emulsifier is the domestic initiative of non-toxic + environmental protection + high efficiency emulsifier. For the removal of oil emulsifier and oil emulsifier, nano-oil emulsifier is used for the removal of oil and oil emulsifier in addition to oil and inorganic oil

- Q: What are the benefits of sanitation

- It's good for the equipment and it's comfortable to watch

- Q: What are the cleaning facilities for the hotel?

- Carpet cleaning: dry foam carpet cleaning machine, steam carpet cleaning machine, (there is a kind of water to wash the carpet cleaning machine, but the equipment use for a long time will damage the carpet, the carpet harden, mildewy, especially pure wool carpet) cannot be used in Hard floor cleaning: multi-function cleaning machine, stone retread machine, polishing machine All you can use is a vacuum cleaner These are the most basic devices.

- Q: What should I consider? To solve the

- Medical ultrasonic cleaning machine, of course, according to the different requirements of its cleaning the specific objects and with different configuration, can be divided into the single slot medical ultrasonic cleaning machine, double groove medical ultrasonic cleaning machines, slot hospital ultrasonic cleaning machine, the experiment with ultrasonic cleaning machine, dental ultrasonic cleaning machine, CNC ultrasonic cleaning machine, etc.

- Q: What is the difference between industrial cleaning equipment and general cleaning equipment?

- One: industrial high pressure cleaning machine: product positioning is machine equipment The industrial high pressure cleaning machine is designed according to the condition of industrial cleaning, the main characteristics are: high reliability, high load capacity, high safety factor. The materials used in machine manufacturing are quite elegant, including manufacturing accuracy, heat treatment of materials, testing and strength tests. The product localization of general cleaning equipment is general tool search Commercial grade washing machine is designed according to general commercial purpose, use high speed and simple structure commonly. Main features: high speed, light and low price, suitable for clean operation of general purpose of field cooperation with low workload and low pressure.

- Q: How often do the reverse osmosis of pure water equipment wash the search?

- Generally 3 ~ 12 months clean, if every month had to be cleaned once, this explanation should improve the pretreatment system, adjust the running parameter. If you need to clean it once or three months, you will need to improve the operating level of the equipment, and it is difficult to determine if you need to improve the pretreatment system.

- Q: The main parameters of ultrasonic cleaning equipment

- Frequency: greater than 20KHz, which can be divided into low frequency, medium frequency, high frequency 3 segments. 2. The power density, power density = transmission power (W)/launch area (cm2) usually acuity 0.3 W/cm2, the higher the power density of the ultrasonic and cavitation effect is stronger, the faster, the better cleaning effect. But for delicate, surface finish, the high power density of long time can be used to "cavorate" the surface of the object. 3. The ultrasonic frequency, ultrasonic frequency is lower, the easier the cavitation in the liquid, the strength is big, has the stronger, is suitable for the workpiece (coarse, dirty) at the beginning of washing. High frequency of ultrasonic direction, suitable for fine cleaning. 4. Clean temperature: generally speaking, ultrasonic at 30 ℃ and 40 ℃ when cavitation effect is best. The higher the temperature, the greater the effect. Normally when actual application of ultrasonic wave, using the working temperature of 50 ℃ to 70 ℃.

- Q: Clean the cleaning parameters of the equipment

- The main cleaning parameters are: Material: the channel is made of stainless steel, acid and alkali resistant, and the appearance is beautiful and generous. Machine: can be customized according to customer's requirement. Power, frequency: adjustable, with unique ultrasonic generator, high energy conversion rate. 4, temperature control, temperature adjustable 0-110 ℃. Scaffolds can be customized according to requirements and actual needs.

- Q: How do you clean the inside of the electric oven? Can you use a wire ball or a detergent?

- First wear latex gloves, detachable parts are removed inside the oven, such as baking, chassis, and then with a neutral detergent washing, paying special attention to oil dirties is very heavy, can use special cleaning fluid, such as the kitchen cleaner to do the key parts of decontamination. Then put an old newspaper in the door of an embedded oven and brush the broken pieces of the oven out of the oven with a small brush. Outside of the inside of the oven to heat pipe and heat pipe shield must use dry cloth to wipe gently, can't use a wet cloth, so as not to affect the heating pipe insulation, leakage phenomenon of short circuit. Except for the removable part of the oven, it is not possible to scrub clean and water with water or a wet cloth. If found the heating tube and fence are dirty, with dry cloth to wipe clean, also can not change with the rough surface such as steel wire ball, clean ball cleaning tools to wipe. If you have wire or hard particles falling into the heating tube, light barbecue an unpleasant feeling of anxious burnt flavour, or cause the entire circuit short circuit, can try to use clean force strong nylon cloth is wiped a few times more. After cleaning the heating tube, you can begin to clean the outer shell of the oven and the inside bladder. The cloth in the diluent of neutral detergent slightly wet, wipe with wet wipe the body shell, dip again after cleaning, diluent, and wring dry, into the oven inside pumice, final reoccupy clear water rinse wipe dry after dry, wipe it twice.

- Q: How many kinds of cleaning equipment are there for cleaning companies?

- Ogilvy Lin cleaning cleaning tool use commonly: 2000 w vacuum suction machine, multi-function cleaning machine, polishing machine, glass scraper, with water, glass cutter, clean ball, microfiber cloth, towel (one-time), glass cleaner, clean neutral detergent, highly-effective cleaning agent, speed powder, seat belts, telescopic rod, brush, herringbone ladder, toolbox, rubber gloves and other professional tool

Send your message to us

Stainless Steel and Galvanized Cleaning Ball Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords