Cleaning Ball Making Machine Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

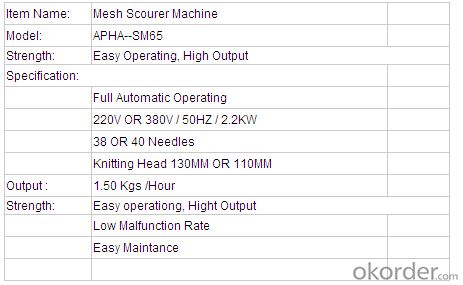

Specifications for Scourer Machine

Automatic cutting the scourers

380V;2.2Kw

8-10kgs/hours

S/S wire 410 and Galvanized wire

BEST PRICE+HIGH QUALITY

single-needle mesh scourer making machine

Standard Edition:

Voltage: 380v; Power (kw): 2.2kw;

Frequency Changer:

Voltage: 220v; Power (kw): 1.5kw;

The yield of each one: 28kgs/8hours for Mesh scourer.

The Weight of the machine:350KG

The size of the machine(mm):1700(L)X660(W)X1500(H)

Featurer for Scourer Machine

Stepless Speed Regulation, Japanese OMRON time controller, automatic counting, size and weight of final scourer could be preset as per requirement.

Not only compression rollers and weaving parts have each separated speed ratio of transmission system, but wire broken stop motion also works well.

Automatic cutting, its shearing tools are hidden blades with multi-sides sawtooth utilizing the latest company technology we owned. It made shearing more accurate, sharper and safer.

Easy operation, one worker controls multiple machines. Wire loading, flatting, mesh waving, and scourer shearing, all finish in one time.

Image of Scourer Machine

|  | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

- Q: The equipment of our unit needs to be cleaned regularly, oil pollution is very much, every time manual washing efficiency is too low, what method can be solved quickly?

- Look at that oil and then choose the emulsifier To use the all-around emulsifier for oil and other oil Used for lubricating oil, mechanical oil and mine Oil, clutch oil, gear oil, brake oil, engine oil, ink, demoulding oil, compressor oil, refrigeration oil, vacuum pump oil, the internal combustion engine oil (1: diesel engine oil. 2: gasoline engine oil. 3: ship oil), oil bearing, guide Rail oil, hydraulic oil, hydraulic oil, metal processing oil dynamic tools, electrical insulating oil, oil, heat conduction oil, rust-proof oil, special occasions, oil, turbine oil, quenching oil, fuel oil, oil have oil selection and other occasions Engine oil emulsifier, no oil emulsifier is the domestic initiative of non-toxic + environmental protection + high efficiency emulsifier. For the removal of oil emulsifier and oil emulsifier, nano-oil emulsifier is used for the removal of oil and oil emulsifier in addition to oil and inorganic oil

- Q: Procter &gamble has some common cleaning equipment in the cleaning of the property

- High pressure rinsing machine: for exterior wall, car and other special cleaning equipment that needs high-pressure water. When activated, it can produce a strong shock flow to remove dust, mud and other dirt.

- Q: What is the cleaning equipment?

- The clean equipment industry has had the "hundred flowers and flowers" situation from scratch, and the quality of clean equipment and the quality and quality of the employees are uneven. Competition is in a state of disorder, the brand operation is chaos, a lack of continuity of effective promotion, users face the numerous brand dazzling, is difficult to choose to compare, the market and industry needs to be changed. The development of clean equipment will be the only way for the development of clean equipment to be made and managed by intensive, centralized resources.

- Q: What is suitable for factory cleaning equipment

- Industrial vacuum cleaner is used to collect waste gas, dust and debris from equipment in industrial production, purify workshop environment, and no secondary pollution. High pressure cleaning machine, clean equipment oil pollution, rust stain, and some areas with small and unsanitary areas.

- Q: Where can I buy cleaning equipment

- Taobao, ali has a lot of, but the preparation factory actually is a few, the basic of taobao is the trafficker... If you haven't done it, try not to buy it, the depth of the device, it's too easy to get into a pit, find a physical store to practice, and see what they're using to buy the best

- Q: The main parameters of ultrasonic cleaning equipment

- Frequency: greater than 20KHz, which can be divided into low frequency, medium frequency, high frequency 3 segments. 2. The power density, power density = transmission power (W)/launch area (cm2) usually acuity 0.3 W/cm2, the higher the power density of the ultrasonic and cavitation effect is stronger, the faster, the better cleaning effect. But for delicate, surface finish, the high power density of long time can be used to "cavorate" the surface of the object. 3. The ultrasonic frequency, ultrasonic frequency is lower, the easier the cavitation in the liquid, the strength is big, has the stronger, is suitable for the workpiece (coarse, dirty) at the beginning of washing. High frequency of ultrasonic direction, suitable for fine cleaning. 4. Clean temperature: generally speaking, ultrasonic at 30 ℃ and 40 ℃ when cavitation effect is best. The higher the temperature, the greater the effect. Normally when actual application of ultrasonic wave, using the working temperature of 50 ℃ to 70 ℃.

- Q: What cleaning equipment does the factory clean equipment need?

- A, plant, Workshop area mainly include workshop and warehouse, the characteristics of the environment is that difficult to clean and dirty, the area is large, the environment need to be efficient driving type washing machine, charge can clean the tens of thousands of square meters area, effectively improve the level of clean. Second, office space The office area usually is laid carpet according to need, so general can not use the ground machine. We need to use a vacuum cleaner for the daily cleaning of the carpet, and if we are not careful with the carpet, we need to use the suction machine. Carpet in the middle of care we need to use dry foam carpet cleaning machine, foam carpet cleaning machines and carpet washing machine and spray carpet smoking machine equipment, such as carpet of general and one month to do a thoroughly clean, can effectively remove dirt. When the carpet is cleaned in the long run, it is difficult to clean thoroughly in the middle and late stage, and then you need to use a carpet washing machine. The carpet washing machine can be used in the middle and later of the carpet to clean the carpet effectively, can make carpet the refurbishment work, the surprise that can surprise unexpectedly! Outdoor squares and open Spaces These places usually area is large, open, open, although it is difficult to clean, but not general cleaning requirements is very high, you just need to keep the floor clean. We recommend sweeping machines to remove dirt and dirt from the ground and keep it clean.

- Q: Article 84 in GMP, the production equipment shall be cleaned according to the operating procedures specified in detail. Production equipment cleaning procedures shall stipulate detailed and complete cleaning methods, cleaning with the name of the equipment or tools, cleaning agents and preparation method, to remove the previous batch identification methods, protect already clean equipment before use from pollution methods, already clean equipment for the longest time limit, preserved...

- It's ok for me to do it myself, and I can clean it for one week. Stay clean during the need after the sweep on the wash room, according to the requirement to avoid cross-contamination if contaminated with other material, and not be removed, the cleaning procedure if need to change the other material pollution, fashioning conservation measures

- Q: What are the appliances cleaning equipment

- A steam engine, a steam engine Air conditioning cleaning machine Water heater cleaning machine Water cooler Multi-function sterilizer Geothermal cleaning machine

- Q: Is there any molding equipment in the car engine?

- The car engine is cleaned with molding equipment. Automobile engine cleaning equipment is mainly used for cleaning the various parts of the car parts such as turbocharger, shock absorber parts, aluminum, iron, copper die casting, ductile iron parts, cylinder block, shell, piston rings, hydraulic parts, compressor spare parts, and so on mechanical hardware parts, cleaning production and processing process or terminal. Such as the typical gj-6000, which is used to clean the grease and dirt of foreign metal parts such as auto supercharger parts. The advantages of rapid cleaning and drying are applicable to batch production.

Send your message to us

Cleaning Ball Making Machine Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords