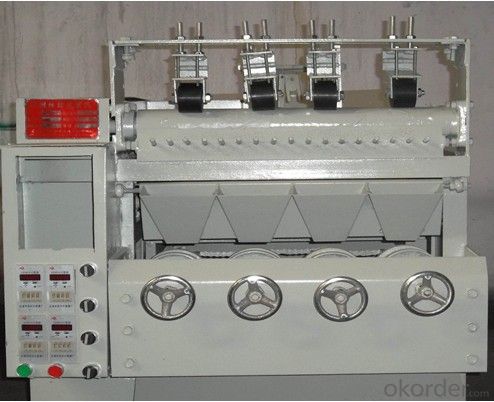

6Wire4Ball ,8Wire4BallScourer Making Machine Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The machine can produce any size and any weight cleaning balls(scourers);In intelligent design,CNC automatic management with ball(scourers)Sub-standard sizes ,so it can control zero-error precision on the weight of each cleaning ball.After separation into the cleaning balls automatically it also can send the cleaning balls with the conveyor belt,Automaticlly,ball tight and losen can be adjusted according to the weight and sizes automatically.So ,it can produce balls with variety and attractive appearance .

Packaging & Delivery

| Packaging Detail: | in bulk, packed by wooden box or according to client's requirements |

| Delivery Detail: | 10-30 working days after prepayment, depends on order quantity |

Specifications

1. machine dimension:160X90X140

2. weight: 330kgs

3. can produce 4 scourers each time

4. advantages: full automatic

Product Name: scourer machine

1. Model: SM-0804 scourer machine

2. product weight: 330kgs/set

3. dimension: 160x90x140cm

4. Packing: wooden box

5. motor: frequency conversion or speed adjustable

6. Port of loading: Qingdao, China

Advantages of scourer machine:

Directly supply from factory

fully automatic machine

long life use, more than 10 years

Delivery time: 10-30 working days after prepayment, depends on order quantity

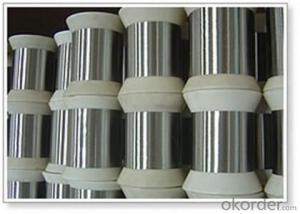

the kitchen scourer produced by scourer making machine is suitable for cleaning: Steel pans, Ceramic, Inox etc., for barbecue grills, dirty tools

Picture for scourer produced by scourer machine

FAQ

1. We are the specialized supplier of stainless steel materials, can provide the best price!

2. We have more than 4 years experience in exporting products to worldwide countries, can provide the high quality products!

3. We have five thousand tons of stock in warehouses with abundant capital. Furthermore, we offer charge sales, credit and 7-day 24-hour services.

4. Wide excellent experiences with after-sale service.

5. Every process will be checked by responsible QC which insures every product's quality.

6. Professional packing teams which keep every packing safely.

7. Trial order can be done in one week.

8. Samples can be provided as your requirements.

- Q: The equipment of our unit needs to be cleaned regularly, oil pollution is very much, every time manual washing efficiency is too low, what method can be solved quickly?

- Normally use a sponge to absorb it, and then paste it with the dough. The equipment is special, and the larger tank is recommended to be manually and relatively clean. The small fuel tank recommended washing during operation and increasing the filter frequency. The best solution is to find the source of the oil, such as external dust pollution, internal wear and tear, and the quality of oil, which is solved by the root cause.

- Q: What are the types of cleaning equipment

- That is too much There are all kinds of homes, there are all kinds of business, and there are all kinds of special things

- Q: Is it better to clean insulators with ultrasonic cleaning equipment or to clean them?

- Certainly is the use of ultrasonic cleaning machine to clean well, because artificial cleaning method in the present used in industry, almost not many people would take such a method, its high cost, slow speed; , by contrast, ultrasonic cleaning machine speed, low cost, through the experiment, using the ultrasonic cleaning machine cleaned insulator can be in 1 to 2 years without washing, is higher than ordinary insulator for 2 times, and save time, is the ideal cleaning method.

- Q: What is the cleaning equipment?

- The clean equipment industry has had the "hundred flowers and flowers" situation from scratch, and the quality of clean equipment and the quality and quality of the employees are uneven. Competition is in a state of disorder, the brand operation is chaos, a lack of continuity of effective promotion, users face the numerous brand dazzling, is difficult to choose to compare, the market and industry needs to be changed. The development of clean equipment will be the only way for the development of clean equipment to be made and managed by intensive, centralized resources.

- Q: Characteristics of cleaning equipment of cleaning equipment

- High pressure water jet cleaning mainly has the following characteristics: (1) selecting the appropriate pressure level, the water jet cleaning will not damage the base of the cleaning equipment. (2) is using ordinary tap water with a high speed washed clean, so it does not pollute the environment, anti-corrosion equipment, won't cause any mechanical damage, can also be removed with chemical cleaning of refractory or cannot dissolve the special scale; (3) after washing, the equipment and parts shall not be cleaned; (4) cleaning parts that are complex in shape and structure, which can be cleaned in a space narrow, complex, hostile and harmful environment; (5) it is easy to achieve mechanization, automation and digital control. (6) save energy, clean efficiency and low cost. Chengdu feng cleaning machine, with its strong technical force and reliable after-sales service protection, the pressure washer in the domestic many areas have a large promotion, cleaning machines are exported to overseas markets, done a good job in the technology field.

- Q: What is the difference between industrial cleaning equipment and general cleaning equipment?

- One: industrial high pressure cleaning machine: product positioning is machine equipment The industrial high pressure cleaning machine is designed according to the condition of industrial cleaning, the main characteristics are: high reliability, high load capacity, high safety factor. The materials used in machine manufacturing are quite elegant, including manufacturing accuracy, heat treatment of materials, testing and strength tests. The product localization of general cleaning equipment is general tool search Commercial grade washing machine is designed according to general commercial purpose, use high speed and simple structure commonly. Main features: high speed, light and low price, suitable for clean operation of general purpose of field cooperation with low workload and low pressure.

- Q: What cleaning equipment does the factory clean equipment need?

- Lucky for you! I am also a factory and recently bought a lot of factory cleaning equipment. As far as I know, the cleaning equipment of the factory can be divided into cleaning equipment and cleaning equipment. Our factory in shenzhen buji there was the last time a company called jie I now, is dedicated to sell industrial cleaning equipment company to buy the machine, the staff attitude is very good, also very professional! Ask for advice if you need it

- Q: Article 84 in GMP, the production equipment shall be cleaned according to the operating procedures specified in detail. Production equipment cleaning procedures shall stipulate detailed and complete cleaning methods, cleaning with the name of the equipment or tools, cleaning agents and preparation method, to remove the previous batch identification methods, protect already clean equipment before use from pollution methods, already clean equipment for the longest time limit, preserved...

- It's ok for me to do it myself, and I can clean it for one week. Stay clean during the need after the sweep on the wash room, according to the requirement to avoid cross-contamination if contaminated with other material, and not be removed, the cleaning procedure if need to change the other material pollution, fashioning conservation measures

- Q: How do you clean the inside of the electric oven? Can you use a wire ball or a detergent?

- Remember a TV show that USES a bowl of lemon water cloth cover, ten minutes of evaporation and then a soft cloth to wipe it off without a chemical smell.

- Q: Is there any molding equipment in the car engine?

- You don't want to take the engine apart and you want to clean up the carbon in it? It's going to be a big problem. Be careful. In case the carbon is filled with oil filters, there is a precedent for the effects of a short period of oil. If it's an engine that's removed and the parts of the engine are cleaned, you can use an ultrasonic cleaning machine (I guess you don't mean that). This is the same as weight loss, normal maintenance is crucial, once the carbon is much carbon, processing is difficult.

Send your message to us

6Wire4Ball ,8Wire4BallScourer Making Machine Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords