AISI420 All Sizes Steel Shot Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

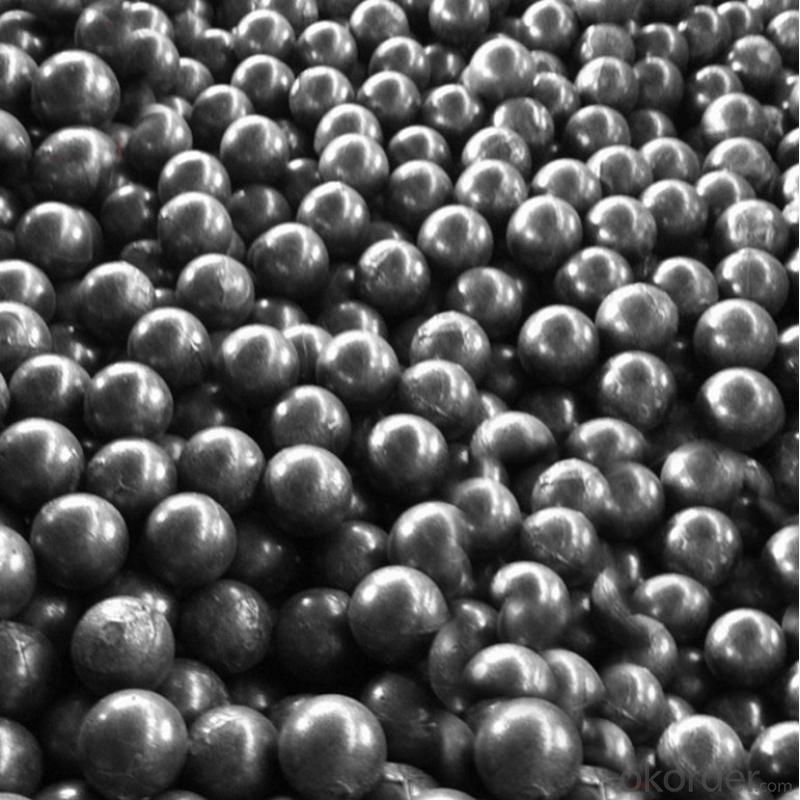

Products Picture

| Product | AISI420 G100 All Sizes Steel Shot Stainless Steel Ball |

| Material | stainless steel |

| Pericision | G100 |

| Hardness | HRC25-39 |

| Surface | zero defect , bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Safe | ROHS |

| Package | four small boxes within a carton of20kg |

Expect the stainless steel ball , we have other steel balls . carbon steel ball , chorme steel ball .

Strict peocess

our company have the strict process :Raw material--Wire drawing--Cold heading--Flashing--Heat treatment--Grinding--Lapping1--Lapping2--Lapping3--Washing--Checking--Packing

High efficiency / High efficiency inspection

Our production capacity is 160 tons per month. we have the high quality testing instruments

for example : roundness measuring equipment , photometric sorter, metallographic structure detector, vibroscope,salt spray tester.

Green product

Our company product are all passed the ISO and SGS certification .

Competitive price: We are a direct steel ball manufacture, lower price is possible

Advanced production flow: With our more than 20 years experience, we have explored compelete production flow, high quality has become an advantage.

- Q: How is steel used in the energy sector, such as in power plants?

- Steel is used extensively in the energy sector, particularly in power plants, due to its strength, durability, and heat resistance properties. It is used in the construction of power plant infrastructure, such as the framework, supports, and beams, as well as in the fabrication of turbines, boilers, and transmission towers. Steel's ability to withstand high temperatures and pressure makes it ideal for containing and transporting steam or other fluids, allowing for efficient energy generation and distribution within power plants.

- Q: What are the different types of steel wires and their applications in the telecommunications industry?

- There are several types of steel wires used in the telecommunications industry. Some common ones include galvanized steel wires, aluminum clad steel wires, and stainless steel wires. Galvanized steel wires are coated with a layer of zinc, which provides corrosion resistance. They are commonly used for overhead transmission lines and communication cables. Aluminum clad steel wires are made by covering a steel core with a layer of aluminum. These wires combine the strength of steel with the light weight and conductivity of aluminum. They are often used in the construction of overhead power lines and telecommunication cables. Stainless steel wires are known for their high strength and resistance to corrosion. They are used in the telecommunications industry for applications that require durability and reliability, such as guy wires for cell towers and suspension cables for overhead lines. Overall, steel wires play a crucial role in telecommunication infrastructure, providing support, strength, and conductivity for various applications in the industry.

- Q: How is steel wire galvanized for fencing applications?

- Steel wire is galvanized for fencing applications by immersing it in a bath of molten zinc. This process, known as hot-dip galvanizing, creates a protective coating on the wire. The wire is first cleaned to remove any impurities, then dipped into the zinc bath, ensuring complete coverage. The zinc coating prevents corrosion and extends the lifespan of the wire, making it suitable for fencing applications.

- Q: What are the different types of steel springs and their uses?

- There are several types of steel springs, each with their specific uses. Some common types include compression springs, extension springs, torsion springs, and flat springs. Compression springs are designed to resist compression forces and are used in applications such as automotive suspensions, mattresses, and industrial machinery. Extension springs, on the other hand, are designed to absorb and store energy when pulled apart and are commonly used in garage doors, trampolines, and various mechanical devices. Torsion springs provide a rotational force and are commonly found in clothespins, garage door systems, and various small appliances. Flat springs, also known as leaf springs, are used in applications that require high strength and flexibility, such as automotive suspensions, agricultural equipment, and heavy machinery. Each type of steel spring has its unique properties and applications, making them essential components in various industries.

- Q: What are the different types of steel profiles used in machinery frames?

- There are several types of steel profiles commonly used in machinery frames. Some of the most common ones include I-beams, H-beams, and C-channels. These profiles are chosen based on their strength, rigidity, and ability to support heavy loads. Each profile has its own unique properties and is selected based on the specific requirements of the machinery frame.

- Q: What are the different grades and specifications of steel products?

- There are various grades and specifications of steel products, each designed for specific applications and requirements. Some common grades include carbon steel, stainless steel, and alloy steel. Carbon steel grades range from low carbon (mild) steel to high carbon steel, with varying levels of strength, durability, and ductility. Stainless steel grades are classified based on their corrosion resistance and can range from austenitic to ferritic or martensitic. Alloy steel grades contain additional elements such as manganese, silicon, nickel, or chromium to enhance specific properties like hardness, toughness, or heat resistance. Additionally, steel products have different specifications such as size, shape, finish, and tolerance levels, which are determined by industry standards and customer needs.

- Q: What are the different types of steel doors and windows?

- There are several different types of steel doors and windows, including flush doors, panel doors, sliding doors, casement windows, and fixed windows.

- Q: How are steel products used in the construction of schools and educational institutions?

- Steel products are widely used in the construction of schools and educational institutions for various purposes. They are commonly used in the structural framework of the buildings, providing strength, durability, and stability. Steel beams, columns, and trusses are used to support the weight of the structure and ensure safety. Additionally, steel is used for roofing systems, walls, and partitions, offering fire resistance and protection against extreme weather conditions. Steel also finds application in the construction of doors, windows, and staircases, providing security and ease of access. Overall, steel products play a crucial role in constructing schools and educational institutions, ensuring a safe and conducive learning environment.

- Q: How is steel used in the construction of infrastructure projects like roads and bridges?

- Steel is commonly used in the construction of infrastructure projects like roads and bridges due to its strength and durability. It is used to reinforce concrete structures, providing the necessary support and stability. Steel is also used in the fabrication of beams, columns, and girders, which form the backbone of bridges and elevated roadways. Its versatility allows for various designs and shapes, ensuring the safety and longevity of these structures.

- Q: What are the different types of steel flooring and decking available?

- There are several types of steel flooring and decking available, including steel grating, steel checker plate, and steel floor decking. Steel grating consists of interlocking bars or grids that provide a strong and durable flooring solution. Steel checker plate features raised patterns or diamond-shaped projections that enhance slip resistance and aesthetic appeal. Steel floor decking is a popular choice for construction projects, as it provides a sturdy and cost-effective solution for creating elevated floors and mezzanines.

Send your message to us

AISI420 All Sizes Steel Shot Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords