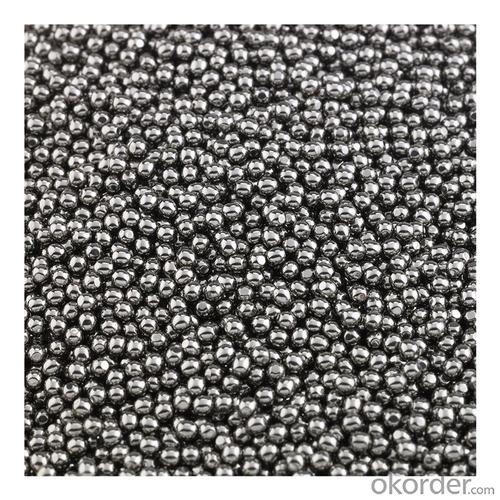

AISI420 Steel Shot All Sizes G100 Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

THE DETAIL OF STAINLESS STEEL BALL

| Product | Stainless steel ball |

| Material | stainless steel |

| Brand | SAIGE |

| Percision | G100 |

| Hardness | HRC>52 |

| Surface | zero defect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

| Certification | ISO9100;2008SGS |

Stainless steel (AISI 420)

AISI 420 have good hardness and fair-to-good corrosion resistance and strength, it is generally used for all applications requiring resistance to corrosion such as bearings, valves, writting instruments, food environment, fresh water, many petroleum products and mild acid environments. AISI 420 is also magnetic.

AISI 420 stainless steel balls in our factory:

Minimum diameter :1.2mm

Best precision :G10

Hardness :HRc>52

THE ADVENTAGE OF STAINLESS STEEL BALL

A, The strict process of stainless steel ball

Raw material--Wire drawing--Cold heading--Flashing--Heat treament--Grinding--Lapping 1--Lapping2--Lapping3--Washing--Checking. All balls must be passed the procedure of passivation. Each procedure have professional inspector. They will check steel balls each two hours to be sure correct diameter and good surface.

B, Sample Free

If you are interested in our product ,we can send you our free sample for you . Please contact us as soon as possible.

SAFE PACKAGE

Step 1: Weighing stainless steel balls. Usually the weight is about 10kg.

Step 2: Sealed plastic bags

Step 3: Put sealed plastic bags into small boxes.

Step 4: Each box has the label, including material, Lot No. Size, quantity, grade, date and so on

Step 5: Each box directly put into mooden case.

High precision stainless steel balls usually is oil package. Normal precision stainless steel balls usually is dry package.

We also can pack them according to customers' request.

- Q: What are the different types of steel sections used in bridges?

- There are several types of steel sections used in bridges, including I-beams, H-beams, box girders, and trusses. These sections are designed to provide strength and stability to the bridge structure, allowing it to withstand the load and forces exerted on it. Each type of steel section has its own unique characteristics and is chosen based on the specific requirements and design considerations of the bridge.

- Q: What are the uses of steel wire mesh in agriculture?

- Steel wire mesh has several uses in agriculture. It is commonly used as fencing to protect crops and livestock from external threats such as animals or trespassers. Additionally, steel wire mesh is used as a trellis system for supporting climbing plants like tomatoes, beans, or grapes, ensuring their proper growth and maximizing yield. It can also be utilized as a protective covering for fruit trees or vegetable beds, preventing damage caused by birds or insects. Overall, steel wire mesh is a versatile tool that aids in securing and enhancing agricultural practices.

- Q: How does steel sheet metal fabrication work?

- Steel sheet metal fabrication is a process that involves cutting, bending, and shaping steel sheets to create various products. It begins with the design phase, where engineers create a blueprint or CAD model of the desired product. Next, the steel sheets are cut using different techniques such as laser cutting or shearing. The cut sheets are then bent into shape using press brakes or other methods, and additional processes like welding or stamping may be used to join or add details to the metal. Finally, the fabricated steel sheet is finished by sanding, painting, or coating to enhance its appearance and protect it from corrosion.

- Q: How are steel wires used in various industries?

- Steel wires are widely used in various industries for their strength and durability. They play a crucial role in sectors such as construction, transportation, manufacturing, and agriculture. In construction, steel wires are used for reinforcing concrete structures, providing added strength and stability. In transportation, they are utilized in the production of automobile parts, aircraft cables, and railway tracks. Steel wires are also essential in manufacturing industries for making springs, cables, and wire mesh. Additionally, they find application in agriculture for fencing, vineyard support, and securing livestock. Overall, steel wires are versatile and indispensable components across a range of industries.

- Q: What are the potential health hazards associated with working with steel products?

- Some potential health hazards associated with working with steel products include exposure to hazardous substances such as metal fumes, dust, and noise. Inhalation of metal fumes and dust can cause respiratory issues and lung diseases, while prolonged exposure to high levels of noise can lead to hearing loss. Additionally, cuts, burns, and other physical injuries can occur while handling steel products. It is important to use proper safety equipment and follow safety protocols to minimize the risks associated with working with steel products.

- Q: How are steel gratings used in industrial flooring?

- Steel gratings are commonly used in industrial flooring as they provide a strong and durable surface for heavy machinery and equipment to operate on. They are designed with an open grid structure, allowing for easy drainage of liquids, debris, and other waste materials. This helps to maintain a clean and safe working environment by reducing the risk of accidents caused by slipping or tripping. Additionally, steel gratings offer excellent load-bearing capabilities, making them ideal for supporting heavy loads and providing structural stability in industrial settings.

- Q: How are steel pipes used in the transportation of natural gas?

- Steel pipes are used in the transportation of natural gas as they provide a reliable and durable means of transporting the gas over long distances. These pipes are designed to withstand high pressure and are resistant to corrosion, making them suitable for the transmission of natural gas. Additionally, steel pipes are able to maintain the integrity of the gas, ensuring minimal leakage and loss during transportation.

- Q: What are the different types of steel sheet and plate materials?

- There are several types of steel sheet and plate materials, including carbon steel, alloy steel, stainless steel, and galvanized steel.

- Q: What are the advantages of using steel in automotive manufacturing?

- There are several advantages to using steel in automotive manufacturing. Firstly, steel is a strong and durable material, providing excellent structural integrity and enhancing the overall safety of vehicles. Additionally, steel is readily available and cost-effective, making it a cost-efficient choice for mass production. Moreover, steel can be easily shaped and molded, allowing for complex designs and customization options. Lastly, steel has a high melting point and is resistant to extreme temperatures, ensuring the longevity and reliability of automotive components.

- Q: What are the safety regulations and standards for steel product manufacturing?

- The safety regulations and standards for steel product manufacturing involve several key aspects. Firstly, the Occupational Safety and Health Administration (OSHA) sets guidelines for workplace safety, including requirements for personal protective equipment, machine guarding, and hazard communication. Additionally, the American National Standards Institute (ANSI) develops standards related to steel product manufacturing, such as specifications for material properties, testing methods, and quality control processes. Furthermore, the American Society of Mechanical Engineers (ASME) provides codes and standards for the design, fabrication, and inspection of steel products to ensure their safe and reliable operation. Compliance with these regulations and standards is crucial to prevent accidents, minimize hazards, and maintain the overall safety of steel product manufacturing processes.

Send your message to us

AISI420 Steel Shot All Sizes G100 Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords