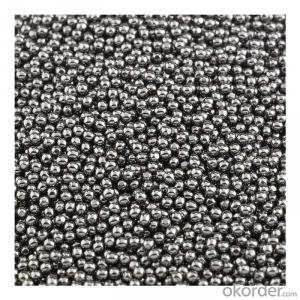

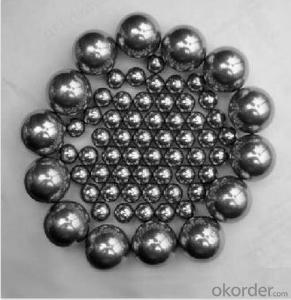

G100 6mm Steel Shot Used Chemcial Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

G100

Certification:

ISO

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

Hereare many kinds of stainless steel balls, AISI 304, AISI 316, AISI 316L, AISI 420, AISI 420C,

AISI 440, AISI 440C.AISI 304 steel ballshave no good hardness but offer good corrosion resistance,

they offer good resistance to atomospheric corrosion, dyes, food processing, valves, sex products and so on.

AISI 304 stainless steel ball in our factory :

Minimum diameter: 2mm

Best precision :G100

Hardness :HRc25-39

| Product | G100 6mm Steel Shot Used Chemcial Stainless Steel Ball |

| Material | stainless steel |

| Test | SGS |

| Percision | G100 |

| Hardness | HRC25-39 |

| Surface | zerodefect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

| Materials Standard | Chemical Composition (%) | Hardness | ||||||

| JIS SUS304 (AISI304) (Din X5CrNi18-10) | C | Cr | Ni | Si | Mn | P | S | HRC25-39 |

| <0.08 | 18.00-20.00 | 8.00-10.50 | <1.0 | <2.0 | <0.045 | <0.030 | ||

The adventage of AISI304 stianless steel ball

A, Safe Package

Step 1: Weighing stainless steel balls. Usually the weight is about 10kg.

Step 2: Sealed plastic bags

Step 3: Put sealed plastic bags into small boxes.

Step 4: Each box has the label, including material, Lot No. Size, quantity, grade, date and so on

Step 5: Each box directly put into mooden case.

High precision stainless steel balls usually is oil package. Normal precision stainless steel balls usually is dry package.

We also can pack them according to customers' request.

B,Sample free

If you are interested in our product , we can send you our free sample for you . Please contact us as soon as possible.

- Q: What are the applications of alloy steel in the aerospace industry?

- Alloy steel finds various applications in the aerospace industry due to its exceptional strength, durability, and resistance to corrosion and high temperatures. It is extensively used in the manufacturing of aircraft components such as landing gears, engine parts, turbine blades, and structural elements. The high strength-to-weight ratio of alloy steel allows for lighter and more fuel-efficient aircraft designs, while its ability to withstand extreme conditions ensures the safety and reliability of aerospace systems.

- Q: What are the different types of steel products used in the energy sector?

- There are various types of steel products used in the energy sector, including pipes, tubes, plates, and structural steel. These products are commonly used in the construction of oil and gas pipelines, power plants, offshore platforms, and renewable energy infrastructure. The specific grade and composition of steel used may vary depending on the requirements of each application, such as corrosion resistance, high temperature stability, or strength.

- Q: How are steel gratings used in the construction of industrial platforms?

- Steel gratings are commonly used in the construction of industrial platforms to provide a strong and durable flooring solution. These gratings are designed to support heavy loads and provide a safe walking surface for workers. They are often used in areas where there is a need for ventilation, drainage, or visibility. Overall, steel gratings play a crucial role in enhancing the stability, safety, and functionality of industrial platforms.

- Q: What are the different types of steel wires and their applications in telecommunications?

- There are several types of steel wires used in telecommunications, including galvanized steel wire, stainless steel wire, and high carbon steel wire. Galvanized steel wire is commonly used for aerial cables and guy wires. It is coated with a layer of zinc to protect it from corrosion and enhance its durability. It provides excellent strength and conductivity, making it suitable for overhead transmission lines. Stainless steel wire is resistant to corrosion and is often used in marine and coastal areas. It is commonly employed for grounding systems and in applications that require high tensile strength and resistance to extreme weather conditions. High carbon steel wire is used for various purposes in telecommunications, including for messenger wires in aerial cables and for strength members in fiber optic cables. It offers exceptional tensile strength and durability, making it suitable for long-distance transmission lines. Overall, the different types of steel wires used in telecommunications cater to specific requirements such as corrosion resistance, strength, and conductivity, ensuring reliable and efficient communication networks.

- Q: What are the potential health hazards associated with working with steel products?

- There are several potential health hazards associated with working with steel products. One major concern is exposure to airborne particles and dust generated during cutting, grinding, or welding processes, which can lead to respiratory issues such as bronchitis or lung cancer. Additionally, steelworking may involve exposure to hazardous chemicals, such as solvents or paints, which can cause skin irritation or even systemic effects if absorbed into the body. Furthermore, repetitive motions involved in steelworking can contribute to musculoskeletal disorders like carpal tunnel syndrome or back pain. Hence, it is crucial for workers in this industry to take proper safety precautions, including the use of personal protective equipment and adherence to safe work practices, to minimize these potential health risks.

- Q: What are the different types of steel scaffolding and support systems available?

- There are several types of steel scaffolding and support systems available, including traditional tube and clamp scaffolding, system scaffolding, frame scaffolding, and mobile scaffolding. Each type has its own advantages and is suited for different applications. Traditional tube and clamp scaffolding is versatile and can be customized to fit any structure, while system scaffolding offers pre-designed components for faster assembly. Frame scaffolding is commonly used in construction projects, and mobile scaffolding is portable and ideal for smaller tasks or maintenance work.

- Q: What are the environmental impacts of producing steel products?

- The environmental impacts of producing steel products include emissions of greenhouse gases, such as carbon dioxide, during the iron and steel production process. Steel production also generates air pollutants, including sulfur dioxide, nitrogen oxide, and particulate matter. Additionally, the extraction of raw materials for steel production can lead to habitat destruction and deforestation. The steel industry also consumes large amounts of water and energy, contributing to resource depletion and potential water and air pollution. Overall, the production of steel products has significant environmental consequences that require sustainable practices and mitigation measures.

- Q: What are the different grades of tool steel and their applications?

- Tool steels are classified into different grades based on their chemical composition and properties. Some common grades include: 1. W-group tool steel: This grade includes water-hardening tool steels such as W1, W2, and W3. They are used for applications like punches, chisels, and woodworking tools. 2. O-group tool steel: Oil-hardening tool steels like O1, O2, and O6 belong to this grade. They offer high hardness, toughness, and wear resistance, making them suitable for cutting tools, punches, and dies. 3. A-group tool steel: Air-hardening tool steels like A2, A3, and A4 are part of this grade. They possess excellent toughness and wear resistance, making them ideal for forming tools, punches, and dies. 4. D-group tool steel: This grade includes high-carbon, high-chromium tool steels like D2, D3, and D6. They offer exceptional wear resistance and are commonly used for cutting tools, dies, and punches. 5. S-group tool steel: Shock-resisting tool steels like S1, S2, and S5 belong to this grade. They possess high impact resistance and are used in applications that involve heavy hammering or shock loads, such as hammers, chisels, and shear blades. 6. H-group tool steel: Hot-work tool steels like H11, H13, and H21 are part of this grade. They retain their hardness and strength at high temperatures, making them suitable for applications such as die casting, forging, and extrusion dies. Each grade of tool steel has specific properties that make it suitable for different applications, allowing for the selection of the most appropriate grade based on the desired performance requirements.

- Q: What are the uses of steel gratings?

- Steel gratings have a wide range of uses, including serving as industrial flooring for platforms, walkways, and staircases, providing ventilation and drainage in areas such as sewage treatment plants and chemical plants, acting as safety barriers or fencing, and supporting heavy loads in construction projects.

- Q: How do steel products contribute to the construction of sports facilities and stadiums?

- Steel products play a crucial role in the construction of sports facilities and stadiums due to their strength, durability, and versatility. From the framework and roof structure to the seating and support systems, steel is widely used in various aspects of sports facility construction. It provides the necessary structural integrity to withstand heavy loads and adverse weather conditions, ensuring the safety and longevity of these venues. Moreover, steel's flexibility allows for innovative and complex architectural designs, enabling the creation of iconic stadiums that capture the essence of sporting events.

Send your message to us

G100 6mm Steel Shot Used Chemcial Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords