AISI420 G100 6mm Shot Magnetic Stainless Steel Balls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Drawn

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

420

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

Product Description

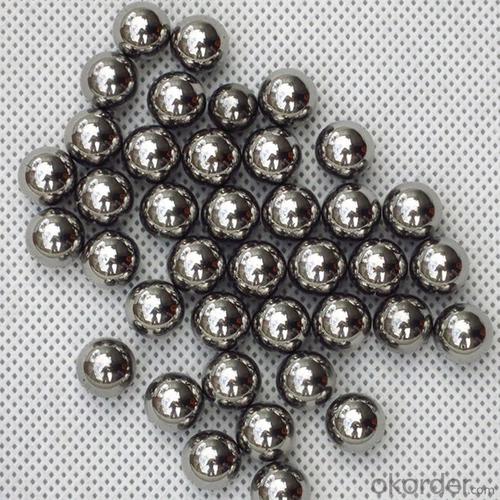

AISI420 G100 6mm Shot Magnetic Stainless Steel Balls

Products Picture

| Product | AISI420 G100 6mm Shot Magnetic Stainless Steel Balls |

| Material | stainless steel |

| Pericision | G100 |

| Hardness | HRC25-39 |

| Surface | zero defect , bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Safe | ROHS |

| Package | four small boxes within a carton of20kg |

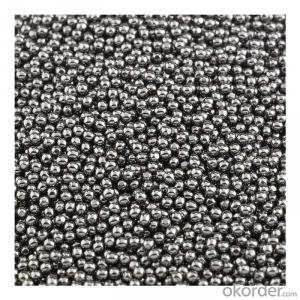

Expect the stainless steel ball , we have other steel balls . carbon steel ball , chrome steel ball .

In our company . The chrome steel ball have used in bearing , screw , grinding . The carbon steel ball have used in bicycle bearing ,slide. The stainless steel ball have used nail polish , grinding chocolate.

WHAT UNIQURE FEATURE DO I HAVE?

Products Picture

our company have the strict process :Raw material--Wire drawing--Cold heading--Flashing--Heat treatment--Grinding--Lapping1--Lapping2--Lapping3--Washing--Checking--Packing

High efficiency / High efficiency inspection

Our production capacity is 160 tons per month. we have the high quality testing instruments

for example : roundness measuring equipment , photometric sorter, metallographic structure detector, vibroscope,salt spray tester.

Green product

Our company product are all passed the ISO and SGS certification . They are all safe.

- Q: What are the different types of steel beams and their uses?

- There are several types of steel beams used in construction, including I-beams, H-beams, and T-beams. I-beams are commonly used for structural support in buildings and bridges, as they have a high strength-to-weight ratio. H-beams, also known as wide flange beams, are used for heavy loads and long spans due to their wider flange and higher load-bearing capacity. T-beams are used in reinforced concrete construction, where the top flange of the beam is embedded in the concrete to provide additional strength. These different types of steel beams offer versatility in various construction applications.

- Q: What are the applications of steel forgings in aerospace?

- Steel forgings have a wide range of applications in aerospace due to their high strength, durability, and reliability. They are commonly used in critical components such as landing gear, engine parts, turbine discs, and structural elements. Steel forgings provide the necessary strength-to-weight ratio and resistance to fatigue and impact that are essential for ensuring the safety and performance of aircraft in demanding operational conditions.

- Q: How is steel used in the manufacturing of mining equipment?

- Steel is used extensively in the manufacturing of mining equipment due to its exceptional strength, durability, and resistance to wear and tear. It is used to construct various components such as drill bits, crushers, conveyor belts, and ore processing machinery, ensuring the equipment can withstand the harsh conditions and heavy loads encountered during mining operations.

- Q: What are the factors to consider when estimating the lifespan of steel structures?

- When estimating the lifespan of steel structures, there are several factors to consider. These include the quality of the steel used, the design and construction of the structure, the environment in which it is located, the level of maintenance and corrosion protection, and any external factors such as earthquakes or extreme weather conditions.

- Q: How are steel products used in the oil and gas industry?

- Steel products are widely used in the oil and gas industry for various applications such as pipelines, drilling equipment, storage tanks, and offshore platforms. Steel's strength, durability, and resistance to corrosion make it an ideal material for these critical components, ensuring reliable and safe operations in the industry.

- Q: What are the different types of steel products used in the manufacturing of gardening tools?

- Some of the different types of steel products used in the manufacturing of gardening tools include stainless steel, carbon steel, and alloy steel. Stainless steel is commonly used for its corrosion resistance and durability, making it suitable for tools exposed to moisture and outdoor conditions. Carbon steel is known for its strength and toughness, making it suitable for heavy-duty tools that require sharp edges, such as pruning shears or hedge trimmers. Alloy steel, a combination of different metals, offers a balance between strength, durability, and affordability, making it a popular choice for various gardening tools like shovels, rakes, and hoes.

- Q: What are the different types of steel profiles used in machinery frames?

- There are several different types of steel profiles that are commonly used in machinery frames. Some of the most common ones include I-beams, C-channels, angles, and square or rectangular tubing. These profiles are chosen based on their structural strength, load-bearing capacity, and overall design requirements of the machinery frame.

- Q: What are the different types of steel flanges and their uses?

- There are several types of steel flanges, including slip-on, socket weld, weld neck, threaded, and blind flanges. Slip-on flanges are used for easy alignment and installation, socket weld flanges provide good strength and leak-proof connections, weld neck flanges are ideal for high-pressure applications, threaded flanges are suitable for low-pressure piping systems, and blind flanges are used to close off the ends of piping systems. Each type of flange has its specific purpose and is chosen based on the requirements of the project.

- Q: How does steel pipe welding work?

- Steel pipe welding works by using heat to melt the edges of the pipes, creating a molten pool. A filler material is then added to the pool, which fuses the edges of the pipes together when it cools and solidifies. This process, known as fusion welding, creates a strong and durable bond between the pipes, ensuring a secure and leak-proof connection.

- Q: How is steel used in the construction of infrastructure projects like roads and bridges?

- Steel is commonly used in the construction of infrastructure projects like roads and bridges due to its strength, durability, and versatility. It is used to create beams, columns, and girders that provide structural support and stability to bridges and overpasses. Additionally, steel is used in reinforcing concrete structures, such as roads and bridge decks, to enhance their strength and prevent cracking. Moreover, steel is also used in guardrails, signposts, and cables, ensuring the safety and functionality of these essential infrastructure projects.

Send your message to us

AISI420 G100 6mm Shot Magnetic Stainless Steel Balls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords