Premium Colorful Corrugated GI Galvanized Metal Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

Premium Colorful Corrugated GI Galvanized Metal Sheet

Galvanized Corrugated Steel Roofing Sheet is formed by cold roll machine, using galvanized steel sheet or aluminum steel as the base material .Galvanized corrugated steel roofing sheet is featured with easy installation ,high strength ,more economic .( low cost )

Product Features

.Outlook Beautiful and novel, rich colors, flexible combination, can be used in different buildingto express special original architectural styles in life.

.Surface have been treated as galvanized and color coated.so it can anti-rain,anti- fire,anti-quake,So it has a long term life as 20-30 year and color just not fade.

. Light weight: easy to transport the material,short the time to finish the building,reduce worker's hard work,save much time and energy for human beings.

.Smooth surface treatment,the dust will be easy taken off by the rain.

. Environmental material,can be used many times,will do no hard to the our environment.

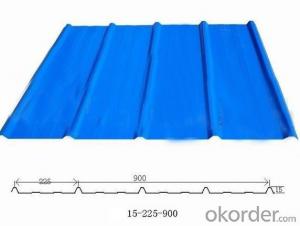

Product Specification

.Thickness:0.13mm to 0.8mm

.Length: 1m to 11.8m.

. Color: navy blue,white grey and any RAL colors.

. Certification: ISO9001:2000.

.Material : cold rolled galvanized steel coil.

. Standard: JIS,DX51D,SGCC,Q235. A653

. advantage: waterproof,light weight, high strength,best price.

. HS code: 7210700000

Packing Information (For 27.5 Tons heavy 20’Fcl)

. water proof paper packing in side

. plastic film Packing in middle

. steel sheet Packing out side

.several steel strip packing to fix the packing

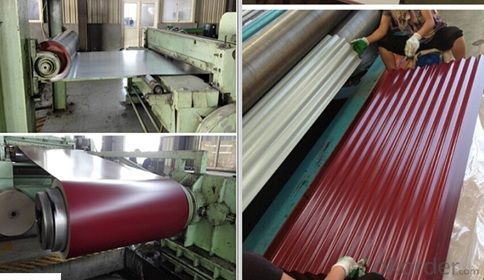

Production Line & Package

FAQ

1. how many wave for per pcs

—— some wave is 8 ,same wave is 9 ,save wave is 11 ,it is up to your request

2. What is the MOQ for this products ?

—— Normally the MOQ is 25mt per size and per color .

- Q: How are steel strips processed for galvanizing?

- Steel strips are processed for galvanizing by first undergoing surface preparation, which involves cleaning the strips to remove any impurities or contaminants. The strips are then immersed in a hot zinc bath, where a metallurgical reaction occurs between the steel and zinc, resulting in the formation of a zinc-iron alloy coating on the surface of the strips. After galvanizing, the coated strips are cooled and inspected for quality before being ready for use.

- Q: How are steel strips tested for impact resistance?

- To ensure the durability and capacity of steel strips to endure sudden forces or impacts, they undergo testing using a variety of methods. One such method is the Charpy impact test, where a notched or pre-cracked sample of the steel strip is struck by a swinging pendulum in a single blow. The energy absorbed during the fracture of the specimen is measured to determine the steel strip's impact resistance. Another method is the drop weight test, where a weight is dropped from a specific height onto a sample of the steel strip. The force and energy absorbed by the strip upon impact are measured, allowing for the evaluation of its impact resistance. Furthermore, the Izod impact test can be used to test steel strips. This test is similar to the Charpy test but involves a different configuration of the specimen. In the Izod test, the sample is clamped vertically, and a swinging pendulum strikes the center of the specimen, causing it to bend and eventually fracture. The energy absorbed during fracture provides valuable insights into the impact resistance of the steel strip. These tests are essential for manufacturers and engineers to assess the ability of steel strips to withstand sudden forces or impacts that may occur during their intended applications. By ensuring the steel strips have sufficient impact resistance, the overall safety and durability of various products and structures that rely on these materials can be guaranteed.

- Q: What are the factors that affect the hardness of steel strips?

- There are several factors that can affect the hardness of steel strips. 1. Carbon content: The carbon content of steel plays a significant role in determining its hardness. Higher carbon content generally leads to increased hardness. 2. Alloying elements: The presence of certain alloying elements such as chromium, manganese, and molybdenum can also impact the hardness of steel strips. These elements can form carbides and increase the overall hardness of the material. 3. Heat treatment: The heat treatment process, including quenching and tempering, can greatly influence the hardness of steel strips. Quenching involves rapid cooling of the material, while tempering is a subsequent heating process that helps to increase toughness and reduce brittleness. 4. Cooling rate: The rate at which the steel strip is cooled during the manufacturing process can affect its hardness. Rapid cooling, such as through water quenching, can result in a harder material compared to slower cooling methods. 5. Grain size: The size of the grains within the steel structure can impact its hardness. Smaller grain sizes generally lead to increased hardness due to a more uniform distribution of carbon and alloying elements. 6. Impurities: The presence of impurities, such as sulfur and phosphorous, can negatively affect the hardness of steel strips. These impurities can form brittle compounds and reduce the overall hardness of the material. 7. Cold working: Cold working, such as rolling or drawing, can increase the hardness of steel strips. This process deforms the material and introduces dislocations, which in turn increase the strength and hardness. 8. Composition and microstructure: The composition and microstructure of the steel, including the presence of phases such as martensite, ferrite, and pearlite, can influence its hardness. These phases form during cooling and can contribute to different levels of hardness. It is important to note that the hardness of steel strips is often a trade-off with other properties such as toughness and ductility. Therefore, finding the right balance between hardness and other desired characteristics is crucial for specific applications.

- Q: Are steel strips resistant to chemicals or acids?

- Yes, steel strips are generally resistant to chemicals and acids due to their inherent corrosion-resistant properties. However, the level of resistance can vary depending on the specific type and composition of steel used.

- Q: How are steel strips processed for fastening?

- Steel strips undergo a series of steps to prepare them for various applications. It all begins by selecting high-quality steel, which is then rolled into thin strips of the desired thickness. These strips are cleaned through processes like degreasing or pickling to eliminate any impurities or contaminants. After the cleaning stage, the steel strips are annealed. This involves heating and slowly cooling them to relieve internal stresses and enhance their ductility. This makes the strips easier to work with and less likely to crack or break during fastening. Once annealed, the steel strips can be further treated based on specific requirements. For instance, they can be coated with protective layers, like zinc or galvanized coatings, to improve corrosion resistance. This is especially important for fastening applications where the strips will be exposed to harsh environmental conditions. To achieve the desired shape and dimensions, the steel strips are cut and shaped using methods like shearing, slitting, or stamping. These processes allow the strips to be tailored to the specific requirements of fastening, ensuring a precise fit and optimal performance. Finally, the processed steel strips are subject to quality control checks to ensure they meet the required standards. This involves testing for mechanical properties, dimensional accuracy, surface finish, and overall integrity. Overall, the processing of steel strips for fastening involves various steps, including cleaning, annealing, coating, shaping, and quality control measures. These steps ensure that the steel strips are well-prepared and suitable for a wide range of fastening applications, offering strength, durability, and reliability.

- Q: How are steel strips embossed or patterned?

- Steel strips can be embossed or patterned through various techniques. One common method is through the use of embossing rolls or dies. These rolls or dies are engraved with specific patterns or designs, which are then pressed onto the steel strip under high pressure. This process creates raised or recessed areas on the surface of the strip, resulting in the desired pattern or design. Another technique used is called laser engraving. In this method, a laser beam is directed onto the steel strip, selectively removing material to create the desired pattern. This process allows for intricate and precise designs to be achieved. Additionally, steel strips can also be patterned using chemical etching. A resist material is applied to the surface of the strip, protecting certain areas from the etching solution. The strip is then immersed in the etching solution, which selectively removes material from the unprotected areas, resulting in the desired pattern. Overall, steel strips can be embossed or patterned using a variety of techniques such as embossing rolls or dies, laser engraving, and chemical etching. These methods offer flexibility in design options and can create visually appealing and functional patterns on steel strips.

- Q: How are steel strips used in the production of wire and cable?

- Steel strips serve as a vital core material in the manufacturing of wire and cable. These strips are typically crafted from robust, high-quality steel, known for its strength and durability. They are usually thin and flat, forming a coiled or wound structure on a spool. To shape the steel strips, they undergo a manufacturing process involving the creation of a specific size and shape. This can be achieved through various methods, such as cold rolling or hot rolling. Cold rolling entails passing the steel strip through a sequence of rollers at room temperature, while hot rolling involves heating the strip before passing it through the rollers. These shaping techniques ensure that the steel strip attains the necessary dimensions and properties required for wire and cable production. After the formation of the steel strips, a protective layer of corrosion-resistant material is typically applied. This coating safeguards the steel from moisture and other environmental elements that may cause rust or deterioration. The coating may consist of different materials, including zinc, tin, or polymer-based compounds. The coated steel strips are then utilized as the core material in the manufacturing of wire and cable. They are commonly positioned at the center of the wire or cable, providing structural support and strength. The steel strip core aids in maintaining the wire or cable's shape and resisting stretching or breaking when subjected to tension. Moreover, the steel strips contribute to the electrical conductivity of the wire or cable. Steel possesses excellent conductivity, and the presence of a steel strip core can enhance the overall conductivity of the wire or cable. In summary, steel strips play a critical role in the production of wire and cable by offering strength, durability, and electrical conductivity to the final product.

- Q: How do steel strips perform in extreme weather conditions?

- Steel strips perform well in extreme weather conditions due to their high strength and durability. They have excellent resistance to corrosion, making them suitable for withstanding harsh elements such as heavy rain, snow, and extreme temperatures. Additionally, steel strips are less prone to warping or cracking, ensuring their performance remains consistent even in challenging weather conditions.

- Q: How are steel strips processed for surface painting?

- Steel strips are processed for surface painting through a series of steps to ensure proper adhesion and durability of the paint. The process typically starts with cleaning the steel strips to remove any contaminants such as dirt, oil, or rust. This can be done through mechanical methods like abrasive blasting or chemical methods like degreasing. Once the steel strips are clean, they are then treated with a coating to improve paint adhesion. This can involve applying a primer or a conversion coating, which chemically reacts with the surface to create a bond between the steel and the paint. The type of coating used depends on the specific requirements of the application. After the coating is applied, the steel strips are dried or cured to allow the coating to fully bond with the surface. This can be done through air drying, baking in ovens, or using infrared heaters, depending on the type of coating and the desired curing time. Once the steel strips are properly cured, they are ready for the application of the paint. The paint can be applied using various methods such as spraying, dipping, or roller coating. The choice of method depends on factors such as the size and shape of the steel strips, the desired finish, and the production volume. After the paint is applied, the steel strips may undergo additional steps such as drying or curing to ensure the paint is fully bonded and dried. This can be done through natural drying or using specialized equipment like drying ovens or UV curing systems. Overall, the process of processing steel strips for surface painting involves cleaning, surface treatment, coating application, drying or curing, and final inspection to ensure a high-quality paint finish that is resistant to corrosion and provides an aesthetically pleasing appearance.

- Q: What is the fatigue strength of a steel strip?

- The fatigue strength of a steel strip refers to its ability to withstand repeated loading and unloading cycles without failure. It is a measure of the strip's resistance to fatigue and is typically determined through fatigue testing.

Send your message to us

Premium Colorful Corrugated GI Galvanized Metal Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords