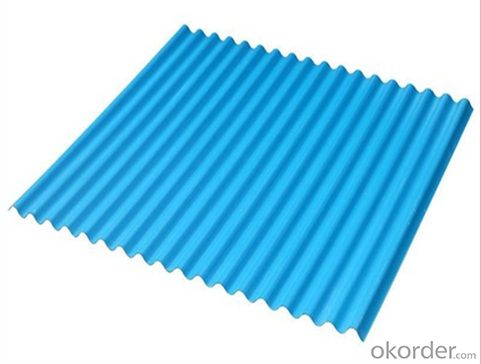

Premium Quality Corrugated Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

Premium Quality Corrugated Galvanized Steel Sheet

Galvanized Corrugated Steel Roofing Sheet is formed by cold roll machine, using galvanized steel sheet or aluminum steel as the base material .Galvanized corrugated steel roofing sheet is featured with easy installation ,high strength ,more economic .(and low cost )

Product Features

.Surface have been treated as galvanized and color coated.so it can anti-rain,anti- fire,anti-quake,So it has a long term life as 20-30 year and color just not fade.

. Light weight: easy to transport the material,short the time to finish the building,reduce worker's hard work,save much time and energy for human beings.

.Smooth surface treatment,the dust will be easy taken off by the rain.

. Environmental material,can be used many times,will do no hard to the our environment.

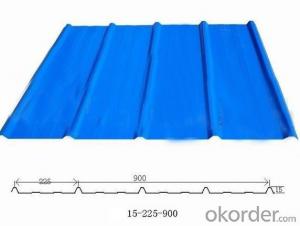

Product Specification

Premium Corrugated GI Galvanized Steel Sheet

Packing Information (For 27.5 Tons heavy 20’Fcl)

. water proof paper packing inside

. plastic film Packing in middle

. steel sheet Packing outside

.several steel strip packing to fix the packing

Production Line & Package

FAQ

1. how many wave for per pcs

—— some wave is 8 ,same wave is 9 ,save wave is 11 ,it is up to your request

2. What is the MOQ for this products ?

—— Normally the MOQ is 25mt per size and per color .

- Q: How are steel strips measured?

- Steel strips are typically measured by their thickness, width, and length using specialized instruments such as calipers, micrometers, or laser gauges.

- Q: How are steel strips used in the manufacturing of metal components?

- Steel strips are commonly used in the manufacturing of metal components as they provide structural strength, durability, and versatility. These strips are typically cut, shaped, and formed into various shapes and sizes to create components such as brackets, hinges, connectors, and reinforcements. Steel strips also serve as a base material for further processing, including stamping, bending, and welding, enabling the production of complex and precise metal components used in industries like automotive, construction, and appliances.

- Q: How are steel strips used in the packaging industry?

- Steel strips are commonly used in the packaging industry as strapping material to secure and stabilize various types of packages. They provide strength, durability, and resistance to damage, making them ideal for bundling heavy or fragile items such as wooden crates, metal components, or construction materials. Steel strips can be tensioned and sealed using manual or automated tools, ensuring that packages remain secure during transportation and storage.

- Q: Can steel strips be used in the production of kitchenware?

- Yes, steel strips can be used in the production of kitchenware. Steel strips are often used to make various kitchen utensils and appliances such as knives, cookware, and cutlery due to their durability, heat resistance, and ease of cleaning.

- Q: Are steel strips used in the production of industrial machinery?

- Steel strips are a common choice in the manufacturing of industrial machinery. They are thin, flat pieces of steel that serve as a raw material in various manufacturing processes. When it comes to machine component construction, like gears, springs, and brackets, steel strips are frequently utilized due to their strength, durability, and versatility. These strips can be easily shaped, bent, and formed into different configurations to meet the specific requirements of the machinery being produced. Moreover, to enhance performance and provide protection against corrosion, steel strips can be heat-treated or coated. In summary, steel strips are vital in the production of industrial machinery, contributing to its quality, reliability, and longevity.

- Q: Can steel strips be welded or soldered?

- Steel strips can indeed be welded or soldered. Welding requires the application of high temperatures and a filler material to melt the steel strips and create a robust connection. Conversely, soldering employs a lower temperature and a filler metal with a lower melting point to unite the steel strips. Both techniques offer secure ways to join steel strips, depending on the unique demands and applications.

- Q: Can steel strips be used in the production of power transmission components?

- Power transmission components can indeed utilize steel strips. Various power transmission components, such as gears, shafts, couplings, and sprockets, frequently employ steel strips during their manufacturing process. Steel possesses exceptional strength, durability, and resistance to wear and tear, which makes it an appropriate material for power transmission applications. The steel strips can be shaped and sized as desired, allowing for the creation of precise and efficient power transmission components. Moreover, the mechanical properties of the steel strips can be improved through heat treatment and surface treatment, further enhancing their performance within power transmission systems. Ultimately, the utilization of steel strips in the production of power transmission components guarantees reliability, longevity, and optimal performance across diverse industrial applications.

- Q: What are the common width tolerances for steel strips?

- The width tolerances for steel strips can vary depending on the specific application and industry standards. Typically, the common range for width tolerances is between +/- 0.005 to 0.020 inches. These tolerances are essential in ensuring that the steel strips meet the necessary dimensional specifications and can be effectively utilized in various manufacturing processes. It should be noted that the width tolerances may differ based on factors such as the grade of steel, the intended use of the strips, and the manufacturing process involved. Moreover, certain industries or applications may have stricter tolerances to guarantee precise and accurate dimensions according to their specific requirements. Therefore, consulting the appropriate industry standards or specifications is crucial in determining the suitable width tolerances for steel strips in a given context.

- Q: How are steel strips protected during storage and shipment?

- Steel strips are typically protected during storage and shipment through a variety of measures. This includes applying a protective coating or oil to prevent corrosion, using rust-resistant packaging materials such as plastic or paper, and ensuring proper stacking and secure strapping to prevent damage or shifting during transit. Additionally, climate-controlled storage facilities may be utilized to maintain optimal conditions and prevent moisture-related issues.

- Q: How are steel strips used in manufacturing?

- Steel strips are widely used in manufacturing for various purposes. One common application is in the production of metal components and parts. These strips are often used as raw materials to create various shapes and sizes of metal parts through processes like stamping, bending, or forming. Steel strips are also commonly used in the automotive industry for manufacturing various parts such as car body panels, brackets, and reinforcements. They provide strength, durability, and corrosion resistance, making them ideal for withstanding the demanding conditions of automotive applications. Moreover, steel strips are extensively used in the production of appliances, machinery, and equipment. They are utilized in manufacturing components like gears, springs, valves, and connectors. The versatility of steel strips allows for the creation of intricate and precise parts that meet the specific requirements of different industries. Additionally, steel strips find applications in the construction industry. They are used for manufacturing structural components like beams, columns, and reinforcement bars. These strips offer high strength and load-bearing capacity, making them essential for constructing buildings, bridges, and other infrastructure projects. Furthermore, steel strips are used in the production of electrical and electronic devices. They are employed in manufacturing components such as transformers, generators, and electrical panels. The magnetic properties of certain steel alloys make them suitable for these applications. In summary, steel strips play a crucial role in the manufacturing industry. Their versatility, strength, and durability make them suitable for a wide range of applications. From automotive and construction to appliances and electronics, steel strips are essential in the production of various components and parts.

Send your message to us

Premium Quality Corrugated Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords