Currugated Galvanized Steel Sheet in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

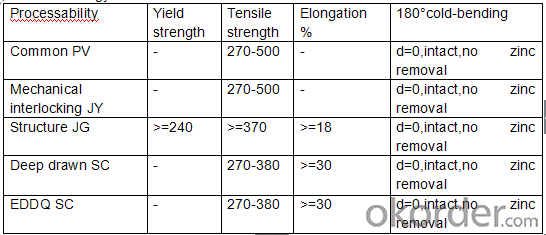

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:Can steel sheets be used in the manufacturing of appliances?

- Appliances can indeed incorporate steel sheets into their manufacturing process. The manufacturing industry heavily relies on steel due to its exceptional qualities of strength, durability, and versatility. Steel sheets can be manipulated to fit various sizes and designs, catering to the unique specifications of different appliances. Furthermore, steel exhibits resistance against corrosion, rendering it suitable for appliances that may encounter water or other liquids. Additionally, steel serves as an exceptional conductor of heat, proving advantageous for appliances that necessitate efficient heat transfer. Consequently, steel sheets are widely employed in the fabrication of appliances, including refrigerators, ovens, dishwashers, washing machines, and numerous others.

- Q:What are the advantages of using galvanized steel sheets?

- Using galvanized steel sheets in various applications offers several advantages. Firstly, they exhibit high resistance to corrosion. The process of galvanizing involves applying a zinc layer to the steel sheets, which acts as a protective barrier against rust and other forms of corrosion. This makes galvanized steel sheets ideal for outdoor applications or environments that are prone to moisture, like construction sites or coastal areas. Secondly, galvanized steel sheets possess excellent durability and longevity. The zinc coating enhances their overall strength and resistance to wear and tear. Consequently, galvanized steel sheets can withstand heavy loads, extreme temperatures, and other harsh conditions, making them suitable for long-term use. Moreover, galvanized steel sheets prove to be cost-effective. Though the initial cost may be slightly higher compared to other materials, their long lifespan and low maintenance requirements offset this investment. Galvanized steel sheets do not require frequent painting or sealing, saving both time and money in the long run. Furthermore, galvanized steel sheets are environmentally friendly. The zinc coating used in the galvanizing process is recyclable, contributing to sustainable practices. Additionally, the extended lifespan of galvanized steel sheets reduces the need for frequent replacements, minimizing waste and conserving resources. Lastly, galvanized steel sheets offer versatility in terms of applications. They can be easily formed, shaped, and cut to meet specific requirements, making them suitable for a wide range of industries, including construction, automotive, and manufacturing. The ability to customize galvanized steel sheets ensures their compatibility with various designs and structural needs. In conclusion, the benefits of using galvanized steel sheets encompass superior corrosion resistance, durability, cost-effectiveness, environmental friendliness, and versatility. These advantages make galvanized steel sheets a favored choice across numerous industries and applications.

- Q:Are steel sheets suitable for pharmaceutical or cleanroom applications?

- Yes, steel sheets are suitable for pharmaceutical or cleanroom applications due to their durability, resistance to corrosion, and ease of cleaning. Additionally, steel sheets can meet the stringent hygiene and cleanliness requirements necessary in these industries.

- Q:How do steel sheets handle weathering?

- Steel sheets handle weathering by forming a protective oxide layer on their surface when exposed to air and moisture. This oxide layer, known as patina, acts as a barrier against further corrosion, making steel sheets highly resistant to weathering effects such as rusting and degradation.

- Q:What are the applications of steel sheets?

- Steel sheets have a wide range of applications across various industries. They are commonly used in construction for structural components, roofing, cladding, and reinforcement. Steel sheets are also utilized in automotive manufacturing for body panels and chassis parts. They find extensive use in the manufacturing of appliances, machinery, and equipment due to their strength and durability. Additionally, steel sheets are employed in the fabrication of storage tanks, pipelines, and shipping containers. Their versatility and resistance to corrosion make them suitable for applications in the marine, aerospace, and energy sectors as well.

- Q:Are steel sheets resistant to staining or discoloration?

- Yes, steel sheets are generally resistant to staining or discoloration due to their inherent properties and protective coatings.

- Q:Are steel sheets resistant to extreme temperatures?

- Yes, steel sheets are generally resistant to extreme temperatures. Steel has a high melting point and can withstand both extremely high and low temperatures without significant deformation or structural damage.

- Q:What is the standard size of a steel sheet?

- The specific application and industry play a significant role in determining the varying standard sizes of steel sheets. However, it is common to find steel sheets in standard sizes like 4 feet by 8 feet (1.2 meters by 2.4 meters) or 5 feet by 10 feet (1.5 meters by 3 meters). These dimensions are widely utilized in construction, manufacturing, and fabrication processes. It is worth mentioning that customized sizes can be obtained to cater to the specific needs of a project or customer.

- Q:What is the difference between a perforated and woven steel sheet?

- A metal sheet with holes or perforations evenly spread across its surface is known as a perforated steel sheet. These holes can come in various shapes and sizes, including round, square, or slotted. Perforated steel sheets are commonly utilized in situations where there is a need for airflow, visibility, or drainage, such as in architectural design, filtration systems, and acoustic panels. The primary advantage of perforated steel sheets is their ability to offer these functionalities while still maintaining their structural integrity. Contrarily, a woven steel sheet is created by intertwining steel wires in a specific pattern. This interlacing results in a mesh-like structure where the wires form intersecting horizontal and vertical lines. Woven steel sheets are frequently employed in applications that require strength, durability, and security, like fencing, guarding, and industrial filtration systems. The main advantage of woven steel sheets is their capability to provide a high level of strength and security due to the tightly interwoven wires. In conclusion, the primary distinction between perforated and woven steel sheets lies in their distinctive structures and functionalities. Perforated steel sheets consist of evenly dispersed holes across their surface, offering advantages such as airflow and visibility. On the other hand, woven steel sheets are formed by intertwining steel wires to create a mesh-like structure, providing benefits such as strength and security. The choice between the two depends on the specific requirements of the given application.

- Q:Are steel sheets suitable for automotive exhaust systems?

- Yes, steel sheets are suitable for automotive exhaust systems. Steel is a commonly used material in the manufacturing of exhaust systems due to its durability, strength, and resistance to high temperatures and corrosion. Automotive exhaust systems are subjected to extreme heat and corrosive gases, and steel sheets are able to withstand these conditions effectively. Additionally, steel sheets can be easily formed and welded, making them suitable for the complex shapes and configurations required in exhaust system components. Overall, steel sheets provide the necessary properties and characteristics required for automotive exhaust systems, making them a suitable choice for this application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Currugated Galvanized Steel Sheet in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords