Steel Billets 3sp 3SP 5SP 20MnSi Brand New Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Billets 3sp 3SP 5SP 20MnSi Brand New Steel Billet

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

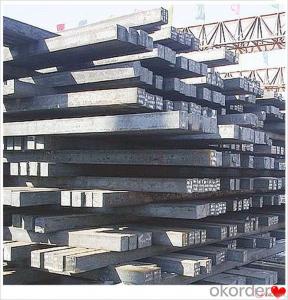

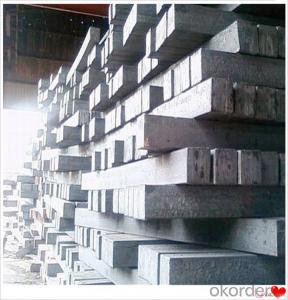

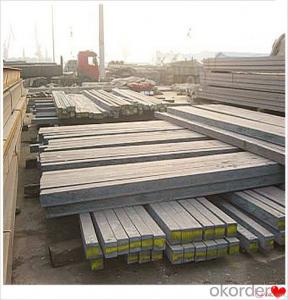

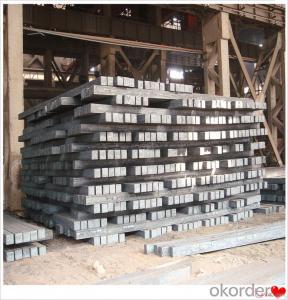

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How are steel billets used in the manufacturing of marine equipment?

- Steel billets are an essential component in the manufacturing of marine equipment due to their unique properties and versatility. These billets, which are semi-finished steel products in a rectangular or square cross-section, play a crucial role in the production of various marine equipment such as ship hulls, propellers, offshore platforms, and marine engines. Firstly, steel billets are used in the construction of ship hulls. The high strength and durability of steel make it an ideal material for withstanding the harsh marine environment, including corrosion, extreme temperatures, and pressure. These billets are forged and shaped into plates, sections, and profiles, which are then welded together to form the hull structure. The use of steel billets ensures that the ship is robust, capable of carrying heavy loads, and resistant to the corrosive effects of seawater. Furthermore, steel billets are utilized in the manufacturing of propellers, one of the most critical components of marine equipment. Propellers are responsible for generating thrust and enabling the movement of ships and boats through the water. Steel billets are forged and machined to create the propeller blades, ensuring they possess the required strength, hardness, and hydrodynamic properties necessary for efficient propulsion. In addition, steel billets are crucial in the construction of offshore platforms used in oil and gas exploration and production. These platforms, which can be fixed or floating, require a robust and stable structure to withstand the harsh marine conditions. Steel billets are used to fabricate the columns, braces, and beams that provide the necessary strength and stability to these platforms. The high load-bearing capacity and corrosion resistance of steel make it an ideal choice for such applications. Lastly, steel billets are employed in the manufacturing of marine engines, which power various vessels. These billets are forged and machined to create the engine components such as crankshafts, connecting rods, and cylinder blocks. Steel's excellent mechanical properties, including high tensile strength, toughness, and wear resistance, ensure that the marine engines can operate reliably and efficiently under demanding conditions. In conclusion, steel billets are indispensable in the manufacturing of marine equipment. They provide the strength, durability, and corrosion resistance required to withstand the harsh marine environment. Whether it is ship hulls, propellers, offshore platforms, or marine engines, steel billets play a vital role in ensuring the safety, performance, and longevity of marine equipment.

- Q: What is the average cost of transporting steel billets?

- The average cost of transporting steel billets can vary depending on various factors such as distance, mode of transportation (road, rail, sea, or air), quantity, and current market conditions. It is advisable to consult with logistics providers or freight companies to obtain accurate and up-to-date pricing information.

- Q: What are the different types of steel billets used in the manufacturing industry?

- The manufacturing industry utilizes various types of steel billets, each possessing unique properties and qualities. Here are a few examples: 1. Carbon Steel Billets: Predominantly composed of iron and carbon, carbon steel billets are widely utilized due to their exceptional strength and durability. They find applications in construction, automotive, and machinery manufacturing sectors. 2. Alloy Steel Billets: By introducing alloying elements like manganese, nickel, chromium, and molybdenum to carbon steel, alloy steel billets exhibit enhanced characteristics such as increased strength, hardness, and resistance to corrosion. They are commonly employed in the production of high-strength components and machinery parts. 3. Stainless Steel Billets: Consisting of iron, chromium, and other alloying elements like nickel and molybdenum, stainless steel billets demonstrate exceptional resistance to corrosion and staining. They are extensively used in the manufacturing of kitchen appliances, automotive parts, and medical equipment. 4. Tool Steel Billets: Tailored specifically for the production of tools, dies, and molds, tool steel billets possess superior hardness, wear resistance, and toughness. These attributes make them ideal for applications involving cutting, shaping, or molding materials. 5. Micro-Alloyed Steel Billets: This category of billets incorporates trace amounts of alloying elements such as vanadium, niobium, or titanium. Micro-alloyed steel billets are employed to enhance the strength and toughness of the steel, rendering them suitable for structural applications in industries like construction and transportation. It is crucial to recognize that these examples represent only a fraction of the various specialized steel billets available in the manufacturing industry. Each type is tailored to meet specific requirements for different applications and industries.

- Q: I want to buy a fishing pole, I don't know how to distinguish it. Know what, please reply, thank you, [em10]!

- When it comes to the differentiation of carbon fishing rods, first of all, what are the different kinds of fishing rods containing carbon?!Carbon rod is now sold in the market are divided into three kinds, namely: carbon, pure carbon, high carbon. These three categories.1, carbon packaging, as its name implies, two layers of material, the outside layer is carbon cloth, the inside layer is glass fiber, epoxy cloth. The price of this kind of rod is lower, because it is not necessary to buy a brand because of the lower price. With a few times you can change, for beginners.2, pure carbon refers to the overall use of 30T below carbon cloth fishing rod, general 24T, 30T based, carbon content of more than 98%. Moderate price.3, high carbon refers to the overall use of more than 30T carbon cloth fishing rod, but not the whole fishing rod is made of a carbon cloth. The tonality of a fishing rod is actually modulated by a different modulus of carbon cloth.Some fishing overall with the 30T following carbon cloth, just use a very small amount of 40T or 46T carbon cloth, called high carbon rod, is actually confuse the public practice of fishing by weighing, hand identification, high carbon rod with real light, hard, two rods in a play, a ratio is obvious.

- Q: How are steel billets used in the production of structural components?

- Steel billets are used in the production of structural components by being heated and molded into desired shapes such as beams, columns, and plates. These billets serve as the starting material, which is then further processed through rolling, forging, or extrusion to create strong and durable structural components used in various industries such as construction, automotive, and aerospace.

- Q: Billet prices skyrocketing weekend, Southern China steel prices rose?

- This week, although steel prices also rose a few days, but since entering November, the price rose a week, a week plummeted, then rebounded sharply, the roller coaster trend, make steel practitioners the feeling of being alone.

- Q: Are steel billets used in the manufacturing of industrial machinery?

- Yes, steel billets are commonly used in the manufacturing of industrial machinery. Steel billets are semi-finished products that are typically produced through a process called continuous casting. These billets serve as the raw material for various types of machinery, including heavy-duty equipment, construction machinery, and machine tools. Steel is a preferred choice for industrial machinery due to its strength, durability, and resistance to wear and tear. Steel billets are often used as the starting material for forging, rolling, or machining processes to create the specific components required for industrial machinery. These components can include gears, shafts, frames, brackets, and other structural parts. The high-quality properties of steel, such as its high tensile strength and excellent mechanical properties, make it an ideal material for withstanding the demanding conditions and heavy loads that industrial machinery is subjected to. Additionally, steel's ability to be easily welded and machined allows manufacturers to produce complex and precise parts for industrial machinery. Overall, steel billets play a crucial role in the manufacturing of industrial machinery, providing the necessary raw material to create strong and reliable components that can withstand the rigors of various industrial applications.

- Q: What is a steel billet?

- A steel billet is a semi-finished product that is created through the process of casting molten steel into a rectangular shape. It typically has a square or rectangular cross-section and is often used as a starting material for various steel products. The size of a steel billet can vary depending on its intended use, but it is typically around 100mm to 200mm square in cross-section and several meters long. Once produced, steel billets are further processed through rolling or extrusion to create different shapes such as bars, rods, wires, or structural steel sections. Steel billets are widely used in the manufacturing industry as a raw material for the production of a wide range of steel products used in construction, automotive, machinery, and many other sectors.

- Q: What are the different forging techniques used for steel billets?

- Steel billets can be forged using various techniques, each with its own benefits and results. Some commonly employed methods for forging steel billets are: 1. Open Die Forging: By placing the steel billet between two flat dies and applying compressive force, it can be shaped. This technique allows for the formation of a wide range of shapes and is often used for large and intricate components. 2. Closed Die Forging: Also known as impression die forging, this method utilizes specially shaped dies with impressions of the desired final shape. The steel billet is positioned between the dies and compressed to conform to the cavities. Closed die forging provides precise control over the shape and dimensions of the end product. 3. Roll Forging: Here, the steel billet is passed through rotating rolls that exert compressive force to shape it. Roll forging is commonly employed for the production of long cylindrical shapes like bars, rods, and shafts. 4. Upset Forging: This technique involves axial compression of the steel billet to increase its cross-sectional area and reduce its length. Upset forging is often used to create thicker sections or increase the material's diameter. 5. Press Forging: Hydraulic or mechanical presses are used in press forging to apply force to the steel billet, shaping it against the die. This method enables precise control over the forging process, making it suitable for intricate shapes or close tolerances. 6. Swaging: Swaging is a forging technique where the diameter of a steel billet is reduced by applying radial compressive force using a series of dies. This process is commonly employed to produce tapered or pointed components like pins, bolts, or needles. Each of these forging techniques offers unique advantages depending on the desired shape, size, and properties of the final product. The choice of forging technique is determined by factors such as part complexity, material properties, production volume, and cost considerations.

- Q: What is the role of steel billets in the manufacturing of offshore structures?

- Steel billets play a crucial role in the manufacturing of offshore structures as they serve as the foundational raw material for creating various components such as beams, columns, and plates. These billets are first heated and then shaped or molded into desired forms through processes like rolling or forging. Their high strength, durability, and resistance to corrosion make them ideal for withstanding the harsh marine environment in which offshore structures operate. Overall, steel billets are essential in ensuring the structural integrity and longevity of offshore structures, providing the necessary strength and stability to withstand the challenging conditions of the open seas.

Send your message to us

Steel Billets 3sp 3SP 5SP 20MnSi Brand New Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords