Carbon Steel Billet 3SP 5SP 20MnSi New design Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Steel Billet 3SP 5SP 20MnSi New design Steel Billet

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

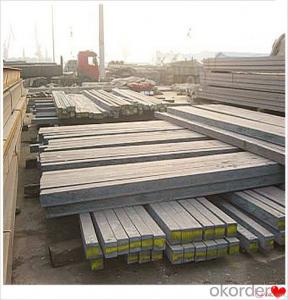

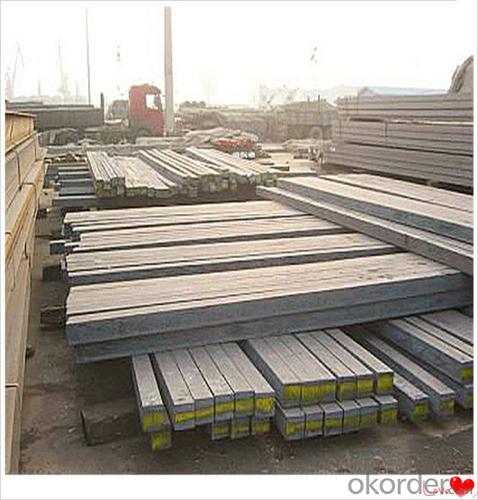

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: What is the average lifespan of a steel billet in the automotive industry?

- The average lifespan of a steel billet in the automotive industry can vary depending on several factors such as the specific application, type of steel used, and maintenance practices. However, on average, steel billets in the automotive industry can last for several years to decades, especially when properly cared for and maintained.

- Q: How are steel billets inspected for internal and surface defects?

- To ensure the quality and integrity of steel billets, various methods are employed to inspect them for internal and surface defects. One commonly used technique for detecting internal flaws is ultrasonic testing. This involves transmitting high-frequency sound waves through the billet and analyzing the reflections received to identify any discontinuities or defects such as cracks, voids, or inclusions. Another method used to inspect internal defects is magnetic particle inspection. This process entails applying a magnetic field to the billet and coating it with iron particles. If there are any internal defects or cracks, they will disrupt the magnetic field, causing the iron particles to accumulate at these locations and become visible under appropriate lighting conditions. When it comes to surface defects, visual inspection is typically the initial step. Expert inspectors visually examine the billet for any visible irregularities like cracks, pits, scratches, or deformities. They may also utilize specialized tools like magnifying glasses or microscopes to ensure a thorough examination. In addition to visual inspection, non-destructive testing techniques can also be employed to detect surface defects. One commonly used method is dye penetrant testing. In this procedure, a colored liquid dye is applied to the surface of the billet. The dye seeps into any surface defects and is later removed, leaving behind a visible indication of the defect. This technique is particularly effective in detecting surface cracks or discontinuities. Another technique used for surface defect inspection is eddy current testing. This technique is based on the principle that a fluctuating magnetic field induces electrical currents in conductive materials like steel. Any surface defects or irregularities will disrupt the induced currents, which can be detected by monitoring changes in the electrical properties of the billet. Eddy current testing is commonly employed to identify surface cracks, pits, or variations in thickness. In conclusion, a combination of these inspection methods allows for a comprehensive evaluation of steel billets, ensuring that both internal and surface defects are identified and addressed before the billets undergo further processing or are used in various applications.

- Q: How do steel billets contribute to the overall thermal insulation of a structure?

- Steel billets do not contribute directly to the overall thermal insulation of a structure. Thermal insulation is primarily achieved through the use of materials with low thermal conductivity, such as insulation boards or panels made from materials like fiberglass, foam, or mineral wool. Steel billets, on the other hand, are typically used as a raw material in the construction industry for various applications, such as the production of steel beams, columns, and other structural components. These components, when properly integrated into a building's structure, can indirectly contribute to the overall thermal insulation of a structure. For instance, steel beams and columns can help support and distribute the load of insulation materials, ensuring they remain in place and perform their insulating function effectively. Additionally, steel components can be designed to minimize thermal bridging, which is the transfer of heat between materials with different thermal conductivities. By reducing thermal bridging, steel components can help maintain a more uniform temperature throughout the structure and prevent heat loss or gain at these junctions. However, it is important to note that the primary role of steel billets in a structure is not thermal insulation. Instead, they provide structural stability, durability, and strength to the building. To achieve optimal thermal insulation, additional materials and construction techniques specifically designed for insulation purposes should be used in conjunction with steel components.

- Q: What are the different types of surface finish defects found in steel billets?

- There are several types of surface finish defects that can be found in steel billets. Some common defects include scale, pits, cracks, and rough surfaces. Scale is a type of oxidation that forms on the surface of the billet and can cause a rough and uneven texture. Pits are small depressions or cavities that can be caused by impurities or improper handling during production. Cracks can occur due to excessive cooling or rapid temperature changes, leading to structural weaknesses in the billet. Rough surfaces can be caused by improper machining or grinding processes, resulting in an uneven or bumpy finish. These defects can affect the quality and integrity of the steel billets, and it is important to detect and address them to ensure the desired end product.

- Q: What are the challenges in welding steel billets?

- There are several challenges that can arise when welding steel billets. One of the main challenges is ensuring proper heat distribution during the welding process. Steel billets are often large and thick, which can make it difficult to evenly distribute heat throughout the material. This can result in inconsistencies in the weld, leading to weak spots or even failure of the joint. Another challenge is the potential for distortion and warping of the billet during the welding process. As heat is applied to the steel, it can cause the material to expand and contract, leading to unwanted changes in shape and dimensions. This can be particularly problematic when welding large or complex structures, as maintaining the desired shape and dimensions becomes critical. Additionally, steel billets can contain impurities and contaminants that can affect the quality of the weld. These impurities, such as sulfur, phosphorus, and other elements, can lead to the formation of brittle zones or other defects in the weld. Proper cleaning and preparation of the billet surface, as well as using appropriate welding techniques and filler materials, are necessary to mitigate these challenges. Furthermore, the high carbon content often found in steel billets can make them prone to cracking during the welding process. Carbon acts as a hardening agent in steel and can increase its susceptibility to cracking, especially if proper preheating and post-weld heat treatment procedures are not followed. Controlling the cooling rate and implementing stress-relieving techniques are essential in preventing cracking and ensuring the integrity of the weld. Lastly, the sheer size and weight of steel billets can present logistical challenges during the welding process. Handling and positioning these heavy objects require specialized equipment and skilled operators to ensure safety and accuracy. Additionally, the need for precise alignment and fit-up can be more challenging with large billets, requiring careful planning and execution. In conclusion, welding steel billets poses challenges such as heat distribution, distortion and warping, impurities and contaminants, carbon-induced cracking, and logistical issues. Overcoming these challenges requires expertise, proper equipment, and adherence to appropriate welding techniques and procedures.

- Q: What are the different types of surface defect detection methods for steel billets?

- There are various types of surface defect detection methods used for steel billets. Some of the commonly employed techniques include visual inspection, magnetic particle inspection, ultrasonic testing, eddy current testing, and laser scanning. 1. Visual Inspection: This is the simplest and most traditional method, where trained inspectors visually examine the surface of steel billets for any signs of defects such as cracks, scratches, or foreign material. 2. Magnetic Particle Inspection (MPI): MPI is a non-destructive testing method that uses magnetic fields and iron particles to detect surface defects. The billet is magnetized, and iron particles are applied to the surface. Any defect causes a leakage of magnetic flux, attracting the iron particles and forming visible indications. 3. Ultrasonic Testing (UT): UT involves the use of high-frequency sound waves to detect internal and surface defects in steel billets. A transducer emits ultrasonic waves into the billet, and the reflected waves are analyzed to identify any flaws or irregularities. 4. Eddy Current Testing (ECT): ECT utilizes electromagnetic induction to detect surface defects. A coil carrying an alternating current is placed near the billet's surface, which generates eddy currents. Any variation in the surface, like cracks or corrosion, alters the eddy currents, and this change is detected by the instrument. 5. Laser Scanning: Laser scanning is a relatively advanced method that uses laser technology to scan the surface of steel billets. The laser beam reflects off the surface, and a sensor analyzes the reflected light to identify any surface defects, such as scratches or dents. These different methods vary in terms of their sensitivity, speed, and cost-effectiveness. The choice of the appropriate surface defect detection method depends on factors such as the required level of accuracy, the type of defects to be detected, and the specific industry requirements.

- Q: How are steel billets used in the production of wire rods?

- Steel billets are a crucial raw material in the production of wire rods. These billets, which are cylindrical in shape, serve as the starting point for the wire rod manufacturing process. The process begins with the heating of steel billets in a furnace to achieve the desired temperature for hot rolling. Once heated, the billets are passed through a series of rolling mills, where they undergo a process called hot rolling. This process involves passing the billets through a set of rollers that gradually reduce their diameter, while increasing their length. As a result, the billets transform into long, thin, and continuous wire rods. During hot rolling, the steel billets undergo plastic deformation, meaning that their shape changes under the application of heat and pressure. This process helps to align the internal grain structure of the steel, resulting in improved mechanical properties such as strength, ductility, and toughness. After the hot rolling process, the wire rods are typically coiled and cooled. They may then undergo further treatments such as pickling, surface coating, or heat treatment to enhance their quality and suitability for specific applications. Finally, the wire rods are ready to be used in various industries, such as automotive, construction, and manufacturing, for the production of a wide range of products, including wires, cables, nails, screws, and reinforcement bars. In summary, steel billets are transformed into wire rods through the process of hot rolling. This process involves heating the billets, passing them through rolling mills to reduce their diameter and increase their length, and then further treating and cooling them. The resulting wire rods are used in a multitude of applications, making them an essential component in the production of various products.

- Q: How do steel billets contribute to the construction industry?

- Steel billets contribute to the construction industry by serving as the raw material for various steel products used in construction. These billets are transformed into beams, columns, rods, and other structural components that provide strength, stability, and durability to buildings and infrastructure. Additionally, steel billets are used in the manufacturing of reinforcements for concrete, enhancing the structural integrity of concrete structures such as bridges, highways, and buildings. Overall, steel billets play a crucial role in the construction industry by providing the necessary materials for safe and reliable structures.

- Q: How are steel billets used in the production of agricultural irrigation systems?

- Steel billets are an essential component in the production of agricultural irrigation systems. These billets, which are semi-finished steel products, are used to create various components of irrigation systems such as pipes, fittings, and valves. When manufacturing irrigation pipes, steel billets serve as the raw material that undergoes a series of processes to form seamless or welded pipes. The billets are heated and then passed through a piercing mill, where they are further elongated and shaped into a hollow tube. These tubes are then stretched and rolled to achieve the desired diameter and thickness. The resulting steel pipes are strong, durable, and resistant to corrosion, making them ideal for use in agricultural irrigation systems. Steel billets are also used to produce fittings and valves for irrigation systems. Fittings such as elbows, tees, and reducers are manufactured by shaping and machining steel billets to meet specific size and shape requirements. These fittings are crucial in connecting and directing water flow within the irrigation system. Additionally, steel billets are sometimes used in the production of pump housings and other structural components of irrigation systems. Due to their strength and stability, steel billets provide the necessary support and durability required in these applications. Overall, steel billets play a vital role in the production of agricultural irrigation systems by providing a reliable and robust material for pipes, fittings, valves, and other components. Their use ensures the longevity and efficiency of these systems, allowing for effective water distribution and irrigation in agricultural fields.

- Q: How to calculate the cost price of billet?

- The ratio of slag to billet (63% fine powder) is about 3:1, which accounts for about 60%. of billet cost

Send your message to us

Carbon Steel Billet 3SP 5SP 20MnSi New design Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords