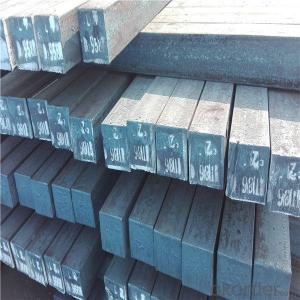

Hot rolled steel billet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

After casting billet is ingot steel products. Mainly from the manufacturing process of billet can be divided into two kinds: die casting billet, slab and the die casting process has been basically eliminated. Mainly from the shape is divided into two kinds:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

use

The editor

Billet was rolled steel, after processing can be used for mechanical parts, forging parts, processing all kinds of steel, steel Q345B channel steel, wire rod is the role of the billet.

Steel billet is used in the production of semi-finished products, generally cannot be used directly for the society. Steel billets and steel are strictly divided into standard, cannot decide to whether the business enterprise of the final product, and according to unified standards to perform the whole society. Typically, billet and the steel is relatively easy to distinguish, but for some steel billet, and have the same specification and same steel purposes (such as rolling tube billet), whether can be used for other industries, whether through steel processing process, whether through a finished product rolling mill processing to distinguish. [1]

3 material

The editor

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The production process

Steel billet is produced by the method of through three processes:

It is through the steelmaking system of continuous casting equipment, directly by the molten steel pouring into billet;

The second is the steelmaking system in the production of steel ingot casting billet through system of steel rolling rolling equipment or processing of steel semi-finished products; Three is the steelmaking system production of steel ingot by forging the semi-finished product processing equipment. [1]

4 market movements

The editor

1, high domestic crude steel production

Although the domestic steel market has been weak in these days, and steel mills deficit to win more less, but it does not seem to affect the enthusiasm of steel production. According to figures from the cisa: early April, the domestic key enterprises crude steel output of 1.6973 million tons, the national forecasts crude steel output of 2.1239 million tons a day. And mid-april although ten-day monthly crude steel output has dropped, but still at a higher level. According to statistics, in the middle of April crude steel output was 1.6891 million tons a day national key enterprises, the national forecasts crude steel output of 2.1158 million tons a day. So much of the production and demand downturn in stark contrast, this also is a drag on one of the important factors of billet prices downward.

2, the billet demand has no obvious improvement

Although has entered the traditional peak season demand, steel billet actual demand situation there is no improvement, even weak parts in March, the market for manufacturer of may is more pessimistic. Currently, tangshan market view, the billet rolling operating at less than 80%, and the rolling factory procurement cautious, inventory control in the low post. Weaker terminal market, steel billet, the rose slightly, weakened purchasing immediately; And the price, demand is also no substantive improvement.

3, tangshan billet falling inventories

It is understood that in April tang shan area each big rolls billet stock began to decline, as of April 28, tangshan billet inventory around 1.25 million tons, than high roughly halved. But there is also a manufacturer said: some resources is made after converted to traders, actually is much larger than the inventory statistics, and 1.25 million tons of steel billet inventory is about 2.5 times in the same period last year.

In addition, China industry insight into network analysts believe the macroeconomic situation is weaker, the negative news is more steel and iron and steel industry the credit crisis will be adverse to the billet market outlook. But considering the steel mills had been losing money in production, make steel billet has certain defensive; And a small long vacation before five billet prices fell back quickly, it is likely to holiday makers to pull up some bedding.

Material standard

The editor

Range of thickness: 150-240 - mm + / - 5 mm width range: 880-1530 - mm + / - 20 mm

Length: 3700-10000 - mm + / - 500 - mm

Cross-sectional size: 64 * 64; 82 * 82; 98 * 98; 124 * 124; 120 * 150; 152 * 164; 152 * 170 mm

Length: 9000 mm

Section of tolerance: billet: 1.0 + / - 2.0-1.0 + / - 1.0 mm slab: width: + / - 2.0 mm thickness: + / - 3.0 mm

The length tolerance: + / - 200 mm

Section diagonal tolerance: 3.5-8.0 MM

Billet section size protrusions requirements: < 1242 mm, do not allow; > = 1242 mm, < = 2 mm 1242 mm, < = 3 mm

Beheading (shear) extension deformation: < 1242 mm billet: no control; The slab: < = 15 mm

Surface tilt: no more than billet section 0.1

Bending: every 1 m length is not more than 10 mm.

- Q: How do steel billets contribute to the marine industry?

- Steel billets are an essential material in the marine industry as they play a crucial role in the construction and maintenance of various marine structures and vessels. These billets, which are essentially semi-finished steel products, are widely used in the marine industry due to their numerous benefits and contributions. Firstly, steel billets are highly durable and possess excellent strength properties. This makes them ideal for applications where resilience against harsh marine conditions, such as corrosion, extreme temperatures, and high-pressure environments, is required. Steel billets are frequently used in the construction of ship hulls, offshore platforms, and other marine structures that need to withstand the challenging conditions of the sea. Furthermore, steel billets can be easily shaped and molded into various forms, enabling their usage in a wide range of marine applications. Their versatility allows for the production of different components and parts, including propeller shafts, engine components, pipelines, and structural beams. Additionally, steel billets are often used in the manufacturing of anchors, chains, and other mooring equipment, which are critical for securing vessels and offshore structures. Moreover, steel billets are known for their excellent weldability, which is vital in the marine industry. Ships and offshore structures often require regular maintenance, repair, and modification. The ability to weld steel billets seamlessly allows for efficient repairs and alterations, ensuring the structural integrity and safety of marine vessels and infrastructure. In terms of sustainability, steel billets have a long lifespan and can be recycled multiple times. This makes them a sustainable choice for the marine industry, as they can be reused in various applications, reducing the demand for new raw materials and minimizing environmental impact. In conclusion, steel billets are indispensable to the marine industry due to their durability, strength, versatility, weldability, and sustainability. These qualities enable their use in the construction, repair, and maintenance of marine structures and vessels, ensuring their reliability and longevity in the challenging marine environment.

- Q: How are steel billets used in the production of marine components?

- Steel billets are an essential component in the manufacturing process of marine parts, including ship propellers, hulls, and offshore structures. These components must possess high levels of strength, durability, and resistance to corrosion in order to endure the harsh conditions of the marine environment. Steel billets are essentially semi-finished products that take the form of solid rectangles. They are typically created by pouring liquid steel into molds and allowing it to cool and solidify. These billets are then utilized as raw materials in the production of various marine components. To begin the production of marine components, steel billets are first heated to a specific temperature in order to soften the material. This process, known as hot rolling, enables the billets to be shaped into different forms such as bars, rods, or sheets, depending on the specific requirements of the component being manufactured. Once the desired shape is achieved, the steel billets undergo additional processes such as forging, machining, and welding. Forging involves applying pressure to the heated billets to mold them into the desired marine component. Machining is then performed to refine the shape, size, and surface finish of the component, ensuring it meets the required specifications. Welding is used to join different steel billets or sections together to create larger marine components, such as ship hulls. The utilization of steel billets in the production of marine components offers numerous advantages. Steel is a robust and durable material that can withstand the extreme forces and conditions encountered in the marine environment. Furthermore, steel possesses excellent corrosion resistance properties, which are vital for marine components exposed to saltwater and other corrosive agents. In conclusion, steel billets play a critical role in the manufacturing of marine components. They serve as the raw materials that are shaped, refined, and joined together to create strong, durable, and corrosion-resistant components for ships, offshore structures, and other marine applications.

- Q: How are steel billets used in the production of automotive components?

- Steel billets are used in the production of automotive components as they are the raw material that is shaped, heated, and then forged or rolled into various shapes and sizes. These billets serve as the building blocks for manufacturing engine parts, suspension systems, chassis components, and other critical automotive parts that require high strength and durability.

- Q: How are steel billets transported and stored?

- Steel billets are typically transported using specialized vehicles such as flatbed trucks or railcars. They are securely loaded onto the transport vehicle using cranes or forklifts. Once transported to their destination, steel billets are usually stored in warehouses or outdoor storage yards. They are often stacked on top of each other, with proper spacing and support to ensure stability. Additionally, to protect against corrosion, steel billets may be coated with a rust-resistant material or stored in a climate-controlled environment.

- Q: How are steel billets used in the production of valves and fittings?

- Valves and fittings heavily rely on steel billets as a vital raw material. These billets, essentially semi-finished steel products, go through various procedures to ultimately attain the desired shape and size of valves and fittings. To begin with, steel billets are heated to a specific temperature in a furnace to increase their malleability. This enables easier shaping and manipulation of the steel during subsequent forming methods. Once heated, the billets are then transferred to a rolling mill where they undergo multiple passes through rollers to gradually decrease their cross-sectional area and length. This hot rolling process refines the steel's grain structure and enhances its mechanical properties. Following hot rolling, the steel billets often undergo further processing using a technique known as extrusion. In this method, the heated billet is pushed through a die, which imparts the desired shape and dimensions onto the steel. Extrusion is commonly employed to produce cylindrical or tubular shapes, which are crucial components in valves and fittings. Once the desired shape is achieved, the extruded steel is typically subjected to heat treatment methods like quenching and tempering to enhance its strength and durability. This ensures that the final valves and fittings can withstand the demanding conditions they will encounter during their operational lifespan. Ultimately, the heat-treated steel is machined and finished to meet the specific requirements of the valves and fittings. This involves processes such as drilling, threading, and surface finishing to attain the necessary dimensions, threads, and smoothness. In conclusion, valves and fittings are produced from steel billets through a series of procedures including heating, hot rolling, extrusion, heat treatment, and machining. These processes guarantee that the resulting valves and fittings possess the necessary strength, durability, and dimensional accuracy needed for their intended applications.

- Q: What are the disadvantages of using steel billets?

- Some potential disadvantages of using steel billets include their high cost, the need for specialized equipment and processes to handle and shape them, and their relatively limited availability compared to other forms of steel. Additionally, steel billets can be susceptible to defects such as cracking or porosity, which may require additional quality control measures.

- Q: How are steel billets used in the production of axles?

- Steel billets are an indispensable element when manufacturing axles, as they serve as the raw material for their production. The initial step in the production process involves heating the steel billets to a specific temperature, which enhances their malleability. This heating process, known as forging or hot rolling, enables the billets to be molded and manipulated into the desired axle shape. Once the billets have reached the appropriate temperature, they are placed in either a forging press or a rolling mill. In the forging process, the billets are subjected to high pressure, resulting in the desired axle shape. This process may involve multiple steps, such as hammering, pressing, or extrusion, to achieve the desired dimensions and shape. Following the forging process, the axle typically undergoes heat treatment to enhance its durability and strength. This involves heating the axle to a specific temperature and then rapidly cooling it through a process called quenching. The heat treatment process aids in improving the axle's hardness and resistance to wear and tear. After the forging and heat treatment processes, the axles may undergo further procedures such as machining, grinding, or finishing. These additional steps are carried out to achieve the required surface finish and dimensional accuracy, ensuring that the axles meet the necessary specifications and can seamlessly integrate into the final product. In conclusion, steel billets play a crucial role in axle production, serving as the starting point for the manufacturing process. They undergo heating, forging, and shaping to create the desired axle form. The resulting axles are then subjected to heat treatment and additional processes to meet specifications. Steel billets are essential for producing top-quality and long-lasting axles, which are critical components in various industries, including automotive, railway, and heavy machinery.

- Q: Can steel billets be used in the production of mining equipment?

- Yes, steel billets can be used in the production of mining equipment. Steel billets are semi-finished products that are commonly used in the manufacturing industry to produce various types of steel products, including mining equipment. The high strength and durability of steel make it an ideal material for mining equipment, which often operates in harsh and demanding environments. Steel billets can be processed and shaped into different components such as gears, shafts, frames, and buckets, which are essential parts of mining equipment. Additionally, steel billets can be easily welded, machined, and heat-treated to meet the specific requirements and standards of mining equipment. Therefore, steel billets play a crucial role in the production of mining equipment by providing the necessary strength and reliability needed for safe and efficient mining operations.

- Q: How do steel billets contribute to the overall durability of a structure?

- Steel billets contribute to the overall durability of a structure by providing a strong and reliable foundation. These billets are made from high-quality steel and undergo a rigorous manufacturing process, resulting in a dense and uniform material. This ensures that the structure has excellent strength, toughness, and resistance to deformation, which helps it withstand various external forces and stresses. Additionally, the uniformity and consistency of steel billets make them less prone to defects and structural weaknesses, enhancing the overall durability and longevity of the structure.

- Q: What are the different types of surface finish inspection methods for steel billets?

- Steel billets can undergo various surface finish inspection methods to determine their quality and suitability for further processing or use. Some commonly used methods for inspecting the surface finish of steel billets include the following: 1. Visual inspection: This method involves visually examining the surface of the billet for any irregularities, such as cracks, pits, scratches, or other imperfections. Although it is a quick and cost-effective method, it may not be able to detect subtle defects. 2. Magnetic particle inspection: This method entails magnetizing the billet's surface and applying fine iron particles to it. Any surface cracks or defects will cause a leakage of the magnetic field, attracting the iron particles and making them visible under appropriate lighting conditions. 3. Dye penetrant inspection: This method involves applying a liquid dye to the billet's surface. The dye seeps into any surface cracks or defects, and after a certain period, excess dye is removed. A developer is then applied, which draws out the dye from the cracks and defects, making them visible. 4. Ultrasonic testing: This method utilizes high-frequency sound waves transmitted through the steel billet. When the waves encounter any surface irregularities, such as cracks or voids, they are reflected back. By analyzing the time taken for the waves to return, the size and depth of the defects can be determined. 5. Eddy current testing: This non-destructive testing method utilizes electromagnetic induction to detect surface defects. An alternating current is passed through a coil, creating a magnetic field. When the coil is near the billet's surface, any defects disrupt the magnetic field, causing a change in the electrical impedance. This change is measured and analyzed to identify surface defects. Each of these inspection methods has its advantages and limitations. The choice of method depends on specific requirements, the size and shape of the billet, and the desired level of accuracy. Manufacturers can ensure the quality and reliability of the steel billets by employing these surface finish inspection methods before further processing or using them in various applications.

Send your message to us

Hot rolled steel billet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords