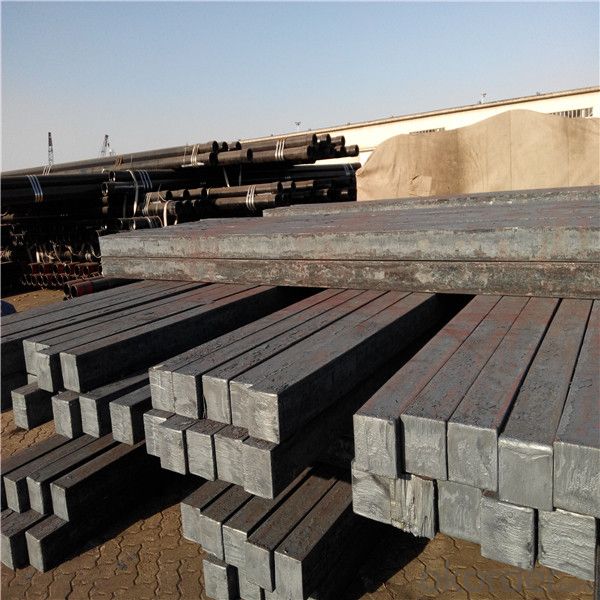

Mild steel billet for hot rolled steel products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15950 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still require

a series of shaping and molding procedures such as hot and cold working, milling and cutting before they

are sold in hardware stores, or used for different applications. The unformed billets, however, can be used

in striking currency such as coins and as reserves, similar to gold bars.

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q:Can steel billets be used for structural purposes?

- Structural purposes can indeed be served by steel billets. These particular steel products are considered semi-finished and are typically shaped through hot-rolling or forging techniques to create various structural components such as beams, columns, and more. Their utilization in construction and engineering projects is widespread due to their ability to provide strength, durability, and the capability to bear heavy loads. Before being incorporated into the construction process, these billets are often further processed and shaped according to specific design requirements. The construction industry heavily relies on steel billets for the construction of buildings, bridges, highways, and other infrastructure projects due to their exceptional mechanical properties and high strength-to-weight ratio. Moreover, their suitability for various structural applications is enhanced by their ease of welding.

- Q:How are steel billets used in the production of molds?

- The production of molds relies heavily on steel billets, which act as the primary material for creating the mold itself. The initial step involves the selection of a suitable steel billet, typically a solid rectangular or square piece of steel. Once chosen, the steel billet undergoes a series of manufacturing processes to transform it into a mold. Initially, the billet is heated to a high temperature referred to as the forging temperature. This heating process is crucial as it enhances the malleability of the steel, making it easier to work with and shape according to the desired form. Following the heating process, the steel billet is subjected to various shaping techniques, including rolling, pressing, or hammering. These techniques aid in shaping the steel into the desired mold design, which can range from simple to complex, depending on the intended application. Upon achieving the desired shape, the steel billet is cooled down and further refined through processes such as machining, grinding, and polishing. These additional processes ensure that the mold's surface finish and dimensional accuracy are refined, resulting in a precise mold capable of producing high-quality products. In summary, steel billets serve as the foundation material in the production of molds. Through shaping and refining processes, customized mold designs are created. These molds find application in diverse industries such as automotive, aerospace, and manufacturing, where they are utilized to manufacture a wide range of products.

- Q:What are the different testing methods used for steel billets?

- Some of the different testing methods used for steel billets include visual inspection, ultrasonic testing, magnetic particle testing, eddy current testing, and hardness testing.

- Q:What are the main safety considerations when handling steel billets?

- The main safety considerations when handling steel billets include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. Proper lifting techniques should be used to prevent strains and back injuries when moving heavy billets. Additionally, ensuring a well-organized and clutter-free work area, as well as proper storage and stacking of the billets, can help prevent accidents and injuries.

- Q:What are the potential applications of steel billets in the electronics industry?

- The electronics industry can benefit from the potential applications of steel billets. While steel is not traditionally associated with this sector, advancements in technology have allowed for its use in various ways. One potential application is using steel billets to produce electronic enclosures. These enclosures offer superior durability and protection for electronic components. They can withstand harsh environments, provide electromagnetic shielding, and prevent damage from impacts or accidents. Manufacturers have the flexibility to shape and form steel billets into different enclosure designs to meet specific requirements. Another application is in manufacturing connectors and terminals. Steel billets can be machined and formed into intricate shapes and sizes, making them suitable for creating reliable and strong connectors. Steel connectors offer excellent conductivity, ensuring efficient and secure connections between electronic components. Additionally, steel's resistance to corrosion makes it a viable option for connectors exposed to moisture or other harsh conditions. Steel billets can also be used to produce high-strength structural components in electronic devices. These components, such as brackets, frames, or supports, require materials with exceptional strength and rigidity. Steel billets, with their high strength-to-weight ratio, provide the necessary structural integrity and stability. Their robustness ensures the longevity and reliability of electronic devices, especially those subjected to heavy loads or vibrations. Furthermore, steel billets can find applications in manufacturing heat sinks. Heat sinks are crucial for dissipating heat generated by electronic components and preventing overheating. Steel, with its excellent thermal conductivity, efficiently transfers heat away from sensitive electronic parts. By shaping steel billets into heat sink designs, manufacturers can create effective cooling systems that enhance the performance and longevity of electronic devices. In conclusion, steel billets have numerous potential applications in the electronics industry. From electronic enclosures to connectors, structural components, and heat sinks, steel's durability, conductivity, and thermal properties make it a valuable material for electronic device production. As technology continues to advance, the use of steel billets in the electronics industry is expected to expand further, offering more innovative solutions for electronic manufacturers.

- Q:What are the different types of surface defect detection methods for steel billets?

- Steel billets are subject to various methods of surface defect detection. Among the techniques commonly used are visual inspection, magnetic particle inspection, ultrasonic testing, eddy current testing, and laser scanning. 1. The simplest and most traditional method is visual inspection, where trained inspectors visually examine the surface of steel billets for cracks, scratches, or foreign material. 2. Magnetic Particle Inspection (MPI) is a non-destructive testing method that uses magnetic fields and iron particles to detect surface defects. The billet is magnetized, and iron particles are applied to the surface. Any defect causes a leakage of magnetic flux, attracting the iron particles and forming visible indications. 3. Ultrasonic Testing (UT) utilizes high-frequency sound waves to detect internal and surface defects in steel billets. Ultrasonic waves are emitted into the billet by a transducer, and the reflected waves are analyzed to identify flaws or irregularities. 4. Eddy Current Testing (ECT) makes use of electromagnetic induction to detect surface defects. A coil carrying an alternating current is placed near the billet's surface, generating eddy currents. Any variation in the surface, such as cracks or corrosion, alters the eddy currents, which are then detected by the instrument. 5. Laser Scanning is a relatively advanced method that employs laser technology to scan the surface of steel billets. The laser beam reflects off the surface, and a sensor analyzes the reflected light to identify surface defects like scratches or dents. These methods differ in terms of sensitivity, speed, and cost-effectiveness. The selection of the appropriate surface defect detection method depends on factors such as the required level of accuracy, the types of defects to be detected, and the specific requirements of the industry.

- Q:What are the different surface defects found in alloy steel billets?

- Some common surface defects found in alloy steel billets include cracks, laps, seams, scabs, and surface scale. These defects can occur during the manufacturing process or as a result of handling and transportation.

- Q:What are the different types of steel billets used in the aerospace industry?

- In the aerospace industry, various types of steel billets are used, including stainless steel, tool steel, and high-strength alloy steel. These types of steel are chosen for their specific properties, such as corrosion resistance, high temperature strength, and superior mechanical properties.

- Q:How do steel billets contribute to the manufacturing of automotive parts?

- The manufacturing of automotive parts heavily relies on steel billets, as they serve as the primary raw material for various components. Steel billets possess excellent strength, durability, and malleability properties, making them indispensable for automotive manufacturers. To begin with, steel billets play a crucial role in the production of engine parts such as crankshafts, connecting rods, and camshafts. These components demand high strength and precision, which can be achieved by utilizing steel billets as the initial material. By heating, forging, and machining the billets, they are shaped into the desired form, ensuring the necessary strength and accuracy for optimal engine performance. Furthermore, suspension and chassis components also heavily rely on steel billets. Control arms, axles, and frame sections necessitate exceptional toughness and resistance to endure the constant stresses and strains experienced by vehicles. Steel billets provide the required mechanical properties to guarantee the safety and longevity of these vital automotive components. In addition, various transmission and drivetrain parts are manufactured using steel billets. Gears, shafts, and differential components require outstanding wear resistance, strength, and dimensional accuracy to ensure the efficiency and reliability of the vehicle's power transmission system. Through forging and machining, steel billets are transformed into these parts, meeting the rigorous standards set by the automotive industry. Moreover, steel billets contribute to the production of body and exterior components such as doors, hoods, fenders, and frames. These parts necessitate high strength, corrosion resistance, and the ability to be shaped into complex forms. Steel billets can be hot or cold rolled, pressed, stamped, or welded to produce these components, providing the necessary structural integrity and aesthetics for automotive bodies. In conclusion, the superior mechanical properties and versatility of steel billets make them vital in the manufacturing of automotive parts. They enable the production of high-quality, durable, and reliable components that meet the demanding requirements of the automotive industry. The use of steel billets ensures the safety, performance, and longevity of vehicles, contributing to the overall quality of the automotive manufacturing process.

- Q:How to calculate the cost price of billet?

- The ratio of slag to billet (63% fine powder) is about 3:1, which accounts for about 60%. of billet cost

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mild steel billet for hot rolled steel products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15950 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords