china reliable PVC Coated/Galvanized/Stainless Steel Welded Wire Mesh manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

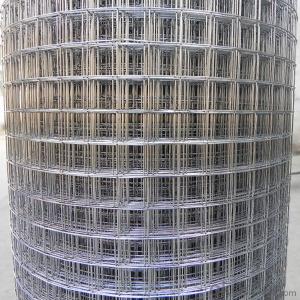

china reliable pvc coated/galvanized/stainless steel Welded Wire Mesh manufacturer

1. Welded Wire Mesh Description:

Welded wire mesh is made from stainless steel wire or galvanized wire, which shows good corrosion-resistance and oxidation-resistance, widely used for poultry houses, egg baskets, runway enclosures, draining racks, porch guards, rat-proofing, safety guards on machines, animal and plant pens and shelves, etc.

2.Main Features of the Welded Wire Mesh:

smooth mesh surface ,well-proportioned meshes ,strong welded points and bright luster .The mesh doesn’t come loose even if cut in parts or being exerted force on parts .Compared with general iron wire ,the products are better in respects of anti-corrosive and anti-rust.

3.Welded Wire Mesh Images

4.Welded Wire Mesh Specification

Specification List of Galvanized Welded Wire Mesh: | ||

Opening | Wire Diameter | |

In inch | In metric unit(mm) | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22,23,24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19,20,21,22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16,17,18,19,20,21,22,23 |

5/8" x 5/8" | 16mm x 16mm | 18,19,20,21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16,17,18,19,20,21 |

1" x 1/2" | 25.4mm x 12.7mm | 16,17,18,19,20,21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14,15,16,17,18,19 |

1" x 2" | 25.4mm x 50.8mm | 14,15,16 |

2" x 2" | 50.8mm x 50.8mm | 12,13,14,15,16 |

Technical Note: 1.Standard roll length: 30m;width: 0.5m to 1.8m 2.Special sizes available at request | ||

Special sizes are also available.

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Australia.

(2)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How is carbon steel different from stainless steel?

- Carbon steel and stainless steel differ primarily in their composition and properties. Carbon steel contains a higher amount of carbon, which makes it more susceptible to rust and corrosion. In contrast, stainless steel contains chromium and other alloys, making it more resistant to rust and corrosion. Stainless steel also has a higher tensile strength and is more durable, while carbon steel is generally cheaper and easier to shape and weld.

- Q: How is steel wire rope manufactured?

- Steel wire rope is manufactured through a multi-step process that involves several stages. First, high-quality steel wires are drawn and formed into individual strands. These strands are then twisted together to form a rope core. Next, additional strands are twisted around the core to create the outer layer. The rope is then subjected to heat treatment to enhance its strength and durability. Finally, it undergoes various finishing processes, such as galvanization or lubrication, to improve its resistance to corrosion and reduce friction.

- Q: What are the different types of steel products used in the manufacturing of outdoor furniture?

- The different types of steel products commonly used in the manufacturing of outdoor furniture include steel tubing, steel rods, steel sheets, and steel plates. These products are used to create the frames, support structures, and surfaces of outdoor furniture pieces such as chairs, tables, and benches.

- Q: How is steel rebar cut and bent for specific construction needs?

- Steel rebar is cut and bent for specific construction needs using specialized tools such as rebar cutters and benders. The rebar is measured according to the required length and then cut using the cutter. To achieve the desired shape, the rebar is then bent using a mechanical or hydraulic bender. This process ensures that the steel rebar is tailored to meet the specific requirements of the construction project, allowing for precise reinforcement and structural support.

- Q: What are the common types of steel products used in the pet photography and videography industry?

- In the pet photography and videography industry, some common types of steel products used include tripods, camera mounts, light stands, and backdrop support systems. These steel products provide stability and durability, ensuring steady shots and capturing the perfect moments with pets.

- Q: How is steel used in the production of musical instruments?

- Steel is commonly used in the production of musical instruments due to its strength and versatility. It is often used in the construction of guitar strings, drum cymbals, and certain parts of brass and woodwind instruments. Steel provides a bright and vibrant sound, making it a popular choice in the manufacturing process.

- Q: What are the different types of steel fasteners and their uses?

- There are several types of steel fasteners commonly used in various applications. Some of the commonly used ones include screws, bolts, nuts, and washers. Screws are threaded fasteners that are designed to be inserted into materials to hold them together. They are available in different sizes and types, such as wood screws, machine screws, and self-tapping screws. Their uses range from fastening wood, metal, or plastic materials to securing electrical components or assembling furniture. Bolts are similar to screws but have a larger and more robust design. They typically require a nut to fasten two or more objects together. Bolts are commonly used in construction, automotive, and machinery industries due to their high strength and durability. Nuts are used in conjunction with bolts to secure them in place. They come in various shapes, such as hexagonal, square, or winged, and are available in different sizes to match the corresponding bolts. Nuts are essential for creating a strong and secure joint in various applications. Washers are thin plates with a hole in the center. They are placed between the nut or bolt head and the surface of the material being fastened. Washers distribute the load and prevent damage to the surface, ensuring a more secure and even connection. They are used in construction, plumbing, and automotive industries. Overall, these different types of steel fasteners play crucial roles in various industries and applications, providing strength, stability, and reliability in joining materials together.

- Q: How are steel products used in the construction of high-rise buildings?

- Steel products are used extensively in the construction of high-rise buildings due to their strength, durability, and versatility. They are commonly used for structural elements such as beams, columns, and frames, providing the necessary support and stability to withstand the weight and forces experienced by tall buildings. Additionally, steel is also used for cladding, roofing, and other architectural features, offering aesthetic appeal and functionality. Overall, steel's superior properties make it an ideal material for constructing safe and efficient high-rise buildings.

- Q: What are the properties of abrasion-resistant steel for industrial equipment?

- Abrasion-resistant steel for industrial equipment possesses several key properties. Firstly, it is extremely durable and can withstand repeated exposure to abrasive substances and environments without getting damaged or worn out easily. Secondly, it has a high hardness level, which enhances its resistance to abrasion and prevents any surface damage. Additionally, this type of steel is often corrosion-resistant, ensuring its longevity and performance in various industrial settings. Lastly, abrasion-resistant steel can be easily fabricated and machined, allowing for customization and easy integration into different equipment designs.

- Q: How do steel products contribute to the water and wastewater treatment sector?

- Steel products contribute to the water and wastewater treatment sector in various ways. Steel is widely used in the construction of water and wastewater treatment plants, as it provides strength, durability, and corrosion resistance. Steel pipes and tanks are commonly used for transporting and storing water and wastewater, ensuring the integrity of the system. Additionally, steel is utilized in the manufacturing of various equipment, such as screens, filters, valves, and pumps, ensuring efficient and reliable operations. Overall, steel products play a crucial role in supporting the infrastructure and functionality of the water and wastewater treatment sector.

Send your message to us

china reliable PVC Coated/Galvanized/Stainless Steel Welded Wire Mesh manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords