Square Steel Billet, Square Bar, Mild Steel Billet Best Price From China Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM,GB,DIN,JIS

Technique:

Hot Rolled

Shape:

Square

Surface Treatment:

Dry

Steel Grade:

Q195,Q215,Q235

Certification:

ISO,SGS,BV,CE

Thickness:

100mm-150mm

Width:

100mm-150mm

Length:

6-12m

Net Weight:

23mt

Packaging:

Standard Export Packing

| Name: | Square bar |

| LENGTH: | 6 meter to 12 meter (+ 50mm) |

| Size: | 100*100, 120*120, 150*150, 200*200 |

| Grade: | 3SP,5SP,Q235,20MnSi. |

| Shape: | Square, Round |

| Technique: | Hot-Rolled |

| Standard: | ASTM/GB |

| BENDING | No more than 5mm in 1 meter No more than 30mm in 6 meter No more than 60mm in 12 meter |

| ANGULAR TWIST | No more than 1 degree per meter and not more than 6 degree over 12 meter length. |

| Chemical composition | C, Si, Mn, P, S, N, etc |

Product Description

Chemical Properties

| Size | 60*60/90*90/100*100/120*120/150*150 |

| Length | 6000mm-12000mm |

| Standard | GB |

| Application | To produce bars or other applications |

| Grade | Q195/Q235/Q275/3SP/5SP/20MnSi |

| Packing terms | TT/LC |

| Package | Mill's standard packing or as client's requirement |

| Delivery time | Within 10-30 days after receiving the deposit or LC |

Chemical Composition

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

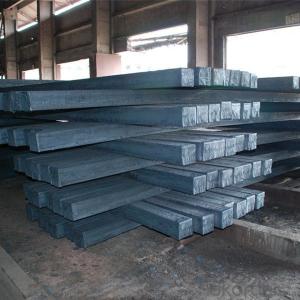

The product show

Packaging:

| Strip:Wooden box or carton box; max 3 tons/wooden box;50kgs/carton box. |

| Coil: Wooden pallet,max 3tons/wooden pallet. |

| Flat bar : wooden box or bundled by waterproof woven cloth, max 3 tons. |

| Sheet/Plate: wooden pallet, max 3 tons |

| Wire: carton box,50~100kgs/CTN |

Shipping

| 20'GP: Max load weight:20 tons |

| 40'GP: Max load weight:25 tons |

| 40'HQ: Max load weight:25 tons |

How to make an order?

· Sample approval

· Client make 30% deposit or open LC after confirming the PI

· Client visit our workshop to check quality or arrange Third-party to inspect the cargo.

· After passed Inspection, then we arrange shipment with shipping agent.

· Supplier arrange necessary documents and send copy of these documents

· Client remit balance payment

· Supplier send original documents or telex release the goods

· Quality warranty for 2year after shipment

After sales service

· After receive the goods, We hope to get your feedback at first time.

· We could provide installation guide, if you need, we could give you global service.

· Our Sales are 24-hours online for your request.

Professional sales

· We value every inquiry sent to us, ensure quick competitive offer.

· We cooperate with customer to bid tenders. Provide all necessary document.

· We are a sales team, with all technical support from engineer team.

- Q: How is steel wire rope used in elevators?

- Steel wire rope is used in elevators to provide the necessary strength and durability to support the weight of the elevator car and passengers. It is used as the primary load-bearing component, connecting the elevator car to the counterweight system and the hoisting machinery. This wire rope is designed to withstand high tensile forces and is crucial for ensuring safe and reliable vertical transportation in elevators.

- Q: How is steel wire galvanized for fencing applications?

- Steel wire is galvanized for fencing applications through a process known as hot-dip galvanization. In this process, the steel wire is cleaned to remove any impurities and then dipped into a molten zinc bath. The wire is completely coated with a layer of zinc, which provides corrosion resistance and durability. This galvanized steel wire is then used for manufacturing fencing products that can withstand harsh environmental conditions and extend their lifespan.

- Q: What are the different types of steel gratings and walkways available?

- There are several different types of steel gratings and walkways available, including welded steel grating, press-locked steel grating, and swage-locked steel grating. These gratings are commonly used for industrial flooring, catwalks, stair treads, and platforms due to their durability and strength. Additionally, there are various surface treatments and finishes available for steel gratings, such as galvanization or powder coating, to enhance their corrosion resistance and aesthetics.

- Q: What are the safety precautions to be taken while handling steel products?

- When handling steel products, it is important to take several safety precautions. Firstly, workers should wear appropriate personal protective equipment (PPE) such as gloves, safety goggles, and steel-toed boots to protect themselves from cuts, burns, and other potential injuries. It is also essential to use proper lifting techniques and equipment to avoid strains and other musculoskeletal injuries. Additionally, workers should be trained to handle steel products safely, including being aware of sharp edges, hot surfaces, and heavy weights. Regular inspections of equipment and work areas should be conducted to identify and address any potential hazards. Lastly, following proper storage and handling procedures, including securing steel products to prevent falling or shifting, can help prevent accidents and injuries.

- Q: How is steel used in the manufacturing of kitchen utensils?

- Steel is used in the manufacturing of kitchen utensils due to its durability, strength, and resistance to corrosion. It is commonly used to make knives, forks, spoons, and various cooking tools like pans and pots. The hardness of steel allows for sharp blades and sturdy handles, ensuring efficient cutting and comfortable grip. Additionally, stainless steel, a type of steel alloy, is often employed to prevent rusting and maintain hygiene in kitchen utensils.

- Q: What are the common types of steel products used in the telecommunications industry?

- The common types of steel products used in the telecommunications industry include steel towers, steel poles, and steel cables. These products are essential for supporting antennas, transmitting signals, and providing stability to telecommunications infrastructure.

- Q: How is steel plate heat-treated for optimal strength?

- Steel plate is heat-treated for optimal strength through a process called quenching and tempering. In this process, the plate is heated to a high temperature, typically above its critical temperature, and then rapidly cooled, or quenched, in water or oil. This rapid cooling helps to harden the steel, making it stronger but also more brittle. To improve its toughness and ductility, the quenched steel is then reheated, or tempered, at a lower temperature. This tempering process helps to relieve internal stresses and allows the steel to regain some of its flexibility and resistance to cracking, resulting in a steel plate with optimal strength.

- Q: What are the different types of steel fasteners and their applications?

- There are several different types of steel fasteners commonly used in various applications. Some of the most common types include bolts, screws, nuts, and washers. Bolts are threaded fasteners that are used to join two or more components together. They come in different sizes and strengths, making them suitable for a wide range of applications such as construction, automotive, and machinery. Screws are similar to bolts but have pointed ends and are typically used to secure objects to a surface or to hold components together. Nuts are threaded fasteners that are used in conjunction with bolts to create a secure joint. They provide additional stability and can be easily tightened or loosened. Washers are flat, disk-shaped fasteners that are placed between a nut or bolt head and the surface of the material being fastened. They help distribute the load and prevent damage to the material. Overall, steel fasteners are essential components used in various industries for their strength, durability, and versatility.

- Q: How is steel used in the construction of railway bridges?

- Steel is commonly used in the construction of railway bridges due to its high strength and durability. It is used to create the structural framework and support systems of the bridge, including the main beams, columns, and trusses. Steel's ability to withstand heavy loads and resist deformation makes it ideal for withstanding the weight of trains and ensuring the bridge remains stable and safe. Additionally, steel is easily fabricated, allowing for efficient construction and maintenance of railway bridges.

- Q: What are the different types of steel coatings?

- There are several different types of steel coatings, including galvanized, stainless, epoxy, and powder coatings.

Send your message to us

Square Steel Billet, Square Bar, Mild Steel Billet Best Price From China Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords