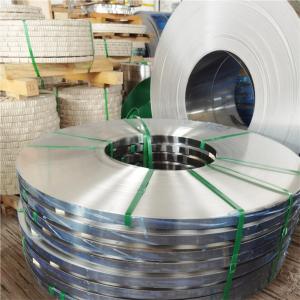

410S Heat treated stainless steel strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 3000 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

410S Heat treated stainless steel strip

Heat treated steel strip is a type of steel strip product that is processed through specific techniques to improve its performance.

Heat treated spring steel strip is a type of strip spring steel that is processed through a heat treatment process. It has the characteristics of high strength, good fatigue resistance, and low hydrogen embrittlement. In addition, the chemical composition of the steel strip is also very good, with high hardness and elasticity.

Heat treated steel strips are widely used in various industrial fields, including but not limited to:

Spring steel strip: such as 65Mn spring steel strip, commonly used for making springs and other components that require high elasticity.

Tool material: such as 440C stainless steel strip, commonly used for making cutting tools and wear-resistant parts.

Other industrial applications, such as conveyor belts, bundling goods, etc., meet the needs of different industrial sectors.

Specification: 0.1mm-3.0mm customizable

Processing technology: Cold rolling, hot rolling

Product Surface: Blue, Black, Silver White

Processing services: deep processing (stamping, bending, etc.), rough processing (cutting, slitting, etc.)

Delivery status: soft, semi hard, fully hard

- Q: What is the machinability of stainless steel strips?

- The machinability of stainless steel strips can vary depending on the specific grade and hardness of the material. Generally, stainless steel strips have good machinability compared to other types of steel due to their higher chromium content which provides improved corrosion resistance and heat resistance. However, stainless steel strips are known to be more difficult to machine compared to carbon steel due to their higher strength and work hardening tendencies. Special care and appropriate cutting tools and techniques are required to achieve the desired machining results. Additionally, the machinability of stainless steel strips may also be influenced by factors such as the presence of other alloying elements, surface finish, and the cutting conditions used.

- Q: Can stainless steel strips be used in oil and gas applications?

- Indeed, oil and gas applications can make effective use of stainless steel strips. Given its exceptional resistance to corrosion, stainless steel proves itself as an optimal choice for environments that involve exposure to corrosive substances like oil and gas. Moreover, stainless steel possesses remarkable strength and durability, both of which are crucial for enduring the high pressure and extreme temperatures typically encountered in oil and gas operations. In this regard, stainless steel strips find utility in various components including pipes, valves, fittings, and tanks, ensuring dependable functionality and longevity throughout the entirety of oil and gas operations.

- Q: What are the weight and length options for stainless steel strips?

- The weight and length options for stainless steel strips can vary depending on the specific requirements and manufacturer. Typically, stainless steel strips come in various weight options ranging from lighter gauges (such as 0.001 inches or less) to heavier gauges (such as 0.125 inches or more). Similarly, length options can vary from shorter coils or rolls to longer lengths, commonly ranging from a few feet to several hundred feet. It is important to consult with the manufacturer or supplier to determine the specific weight and length options available for stainless steel strips.

- Q: Can stainless steel strips be used in chemical processing plants?

- Yes, stainless steel strips can be used in chemical processing plants. Stainless steel is highly resistant to corrosion, making it suitable for handling various chemicals and corrosive substances in such environments. Its durability, strength, and hygienic properties make it an ideal choice for applications in chemical processing plants.

- Q: How do stainless steel strips perform in the presence of sulfuric acid?

- Stainless steel strips have excellent resistance to sulfuric acid, making them highly suitable for use in environments with sulfuric acid.

- Q: What are the common surface finishes for stainless steel strips?

- Common surface finishes for stainless steel strips include: 1. Mill Finish: This is the basic finish that is achieved after the stainless steel strip has been hot or cold rolled. It has a dull, non-reflective appearance. 2. Brushed Finish: This finish is created by brushing the stainless steel strip with abrasive materials, resulting in a textured appearance. It helps to hide surface imperfections and gives the strip a satin-like finish. 3. Polished Finish: The stainless steel strip is mechanically polished to create a smooth, reflective surface. This finish is commonly used for decorative purposes and is available in various levels of polish, such as mirror polish or satin polish. 4. Embossed Finish: In this finish, the stainless steel strip is passed through embossing rollers that create raised or sunken patterns on the surface. It adds texture and visual interest to the strip. 5. Patterned Finish: Stainless steel strips can be patterned using various techniques, such as etching or laser engraving. This creates decorative patterns or designs on the surface, giving the strip a unique and distinctive look. 6. Coated Finish: Stainless steel strips can be coated with a thin layer of another material, such as a polymer or a metal, to enhance its appearance or provide additional protection against corrosion. These are some of the common surface finishes for stainless steel strips, each offering different aesthetics and functionality to suit various applications.

- Q: Are stainless steel strips suitable for marine environments?

- Stainless steel strips prove to be an ideal choice for marine environments due to their exceptional resistance to corrosion. The remarkable anti-corrosive properties of stainless steel have earned it a prominent position in various marine applications. The presence of chromium in stainless steel triggers the formation of a safeguarding oxide layer on its surface, effectively preventing both rusting and corrosion. This oxide layer serves as a formidable barrier, shielding the steel from the harsh marine conditions, including saltwater, moisture, and humidity. Moreover, stainless steel possesses formidable strength and durability, enabling it to withstand the rigorous demands that marine environments impose, such as waves, impacts, and fluctuations in temperature. Consequently, stainless steel strips are extensively utilized in marine sectors like boat construction, shipbuilding, offshore structures, and marine equipment.

- Q: Can stainless steel strips be used for solar panel frames?

- Yes, stainless steel strips can be used for solar panel frames. Stainless steel is known for its strength, durability, and resistance to corrosion, making it a suitable material choice for solar panel frames that need to withstand outdoor conditions. Additionally, stainless steel's high melting point and ability to handle thermal expansion make it well-suited for solar panel frames that are exposed to high temperatures.

- Q: Can stainless steel strips be used in architectural applications?

- Architectural applications can indeed make use of stainless steel strips. This versatile material boasts a range of advantages that make it suitable for architectural projects. Notably, stainless steel is renowned for its resistance to corrosion, its durability, and its aesthetic appeal. It is possible to incorporate stainless steel strips into a variety of architectural features, including cladding, roofing, handrails, decorative panels, and trim. These strips can be tailored to specific design requirements, taking on different shapes and sizes as needed. Furthermore, stainless steel strips provide flexibility when it comes to finishes, allowing architects to achieve a variety of looks and textures. All in all, stainless steel strips are a popular choice in architectural applications due to their strength, longevity, and ability to withstand harsh environmental conditions.

- Q: How are stainless steel strips manufactured?

- Stainless steel strips are manufactured through a process called hot rolling, where stainless steel ingots are heated and passed through a series of rolling mills to reduce their thickness and shape them into long, thin strips. The strips are then annealed to relieve any stresses and improve their mechanical properties. Finally, they undergo pickling and passivation treatments to remove impurities and enhance corrosion resistance.

Send your message to us

410S Heat treated stainless steel strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 3000 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches