Steel sheets for sale wholesale china import

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 57483 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

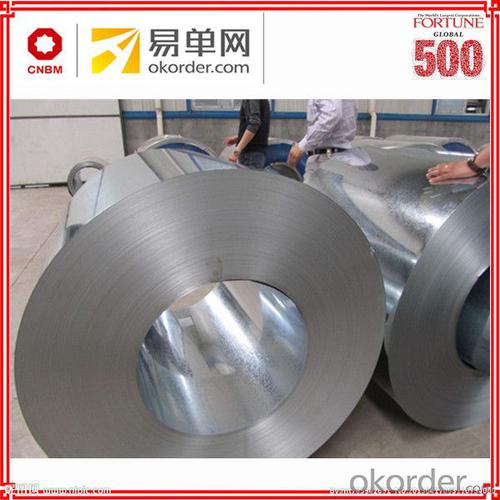

Cold rolled sheet products have been available for many, many years, and have been successfully used for a multitude of

applications. Today's cold rolled sheet products are much improved over those used in the past. They offer better control of

thickness, shape, width, surface finish, and other special quality features that compliment the emerging need for highly

engineered end use applications.

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal for deep

drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition

and their mechanical properties, which guarantees processing consistency.

.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

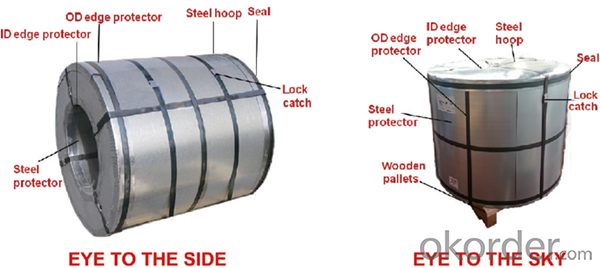

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will

provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing

as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: Are steel sheets available in different patterns or textures?

- Yes, steel sheets are available in different patterns and textures.

- Q: Can steel sheets be perforated or punched?

- Yes, steel sheets can be perforated or punched. Perforating or punching involves creating holes or designs in the steel sheet using specialized tools or machinery. This process is commonly used in various industries such as construction, automotive, and manufacturing to achieve specific functionality or aesthetics in the steel sheet.

- Q: Can the steel sheets be bent or formed into different shapes?

- Yes, steel sheets can be bent or formed into different shapes. Steel is a highly malleable material, which means it can be easily manipulated and shaped without breaking. This allows for a wide range of applications where steel sheets need to be bent or formed into specific shapes, such as in the construction industry for manufacturing beams, columns, and other structural components. Various methods, such as cold forming, hot forming, and press braking, can be used to bend or form steel sheets into different shapes, depending on the desired end result and the thickness of the steel.

- Q: What are the properties of steel sheets?

- Steel sheets possess several desirable properties that make them highly sought after in numerous industries. Firstly, their exceptional strength and durability are well-known. They have the ability to withstand heavy loads and exhibit a high resistance to impact and deformation. Consequently, they are considered ideal for applications where strength is paramount, such as in the construction, automotive, and aerospace sectors. Another noteworthy characteristic of steel sheets is their excellent corrosion resistance. Typically, steel is coated with a thin layer of zinc or other protective materials to prevent rusting and corrosion. This protective coating enhances the longevity of steel sheets, enabling their use in outdoor or humid environments without the risk of degradation. Steel sheets are also renowned for their versatility. They can be easily bent, shaped, and welded, making them suitable for various fabrication processes. This adaptability empowers manufacturers to effortlessly create intricate structures and components, rendering steel sheets a popular choice in architectural and industrial designs. Furthermore, steel sheets exhibit excellent thermal conductivity. This property enables them to efficiently transfer and distribute heat, making them well-suited for applications that require temperature regulation, such as in heating systems or electrical appliances. Lastly, steel sheets are highly recyclable, rendering them an environmentally-friendly option. Steel is one of the most recycled materials worldwide, and the recycling process does not compromise its properties or quality. This sustainability factor establishes steel sheets as the preferred choice for those seeking eco-friendly materials. In conclusion, the properties of steel sheets encompass strength, durability, corrosion resistance, versatility, thermal conductivity, and recyclability. These qualities make steel sheets a reliable and versatile material for a wide range of industries and applications.

- Q: What is the typical weather resistance of a steel sheet?

- The typical weather resistance of a steel sheet depends on its specific composition and surface treatment. However, in general, steel sheets are known for their excellent weather resistance. They are often coated with protective layers such as zinc or paint, which enhance their ability to withstand harsh weather conditions such as rain, snow, and UV radiation. This coating acts as a barrier, preventing moisture from penetrating the steel and causing corrosion. Furthermore, steel sheets are typically designed to be durable and long-lasting, making them a reliable choice for outdoor applications exposed to various weather elements.

- Q: Are steel sheets resistant to warping or bending?

- Yes, steel sheets are known for their high resistance to warping or bending due to their strong and rigid nature.

- Q: Can steel sheets be rolled into cylinders or tubes?

- Yes, steel sheets can be rolled into cylinders or tubes through a process known as tube or pipe rolling.

- Q: What are the potential drawbacks of using steel sheets?

- There are several potential drawbacks of using steel sheets in various applications. Firstly, steel sheets are prone to corrosion. If not properly protected or coated, steel sheets can rust when exposed to moisture or certain environmental conditions. This can significantly affect their structural integrity and lifespan. Secondly, steel sheets can be heavy and difficult to handle. This can pose challenges during transportation, installation, and maintenance. The weight of steel sheets may also limit their use in certain applications where weight restrictions are in place. Additionally, steel sheets can be expensive compared to other materials. The cost of steel production, processing, and customization can be higher than alternative materials, making steel sheets less financially viable in some projects. Another potential drawback of steel sheets is their limited design flexibility. Steel sheets are often manufactured in standard sizes and shapes, which may not always meet specific design requirements. Modifying steel sheets can be time-consuming and costly, limiting their adaptability for unique or complex projects. Moreover, steel sheets have a relatively high thermal conductivity. This means that they can transfer heat quickly, making them less effective in providing insulation. In applications where thermal insulation is crucial, alternative materials may be more suitable. Lastly, steel sheets are not environmentally friendly. The production of steel involves significant energy consumption and carbon emissions. Additionally, the extraction and mining of raw materials used in steel production can have detrimental effects on the environment. Overall, while steel sheets have numerous advantages such as strength and durability, it is important to consider these potential drawbacks when choosing the appropriate material for a specific application.

- Q: Can steel sheets be customized according to specific requirements?

- Yes, steel sheets can be customized to meet specific requirements.

- Q: How do steel sheets perform in terms of noise reduction?

- Steel sheets are highly effective in reducing noise due to their dense and rigid nature. They effectively block and absorb sound waves, resulting in significant noise reduction.

Send your message to us

Steel sheets for sale wholesale china import

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 57483 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords