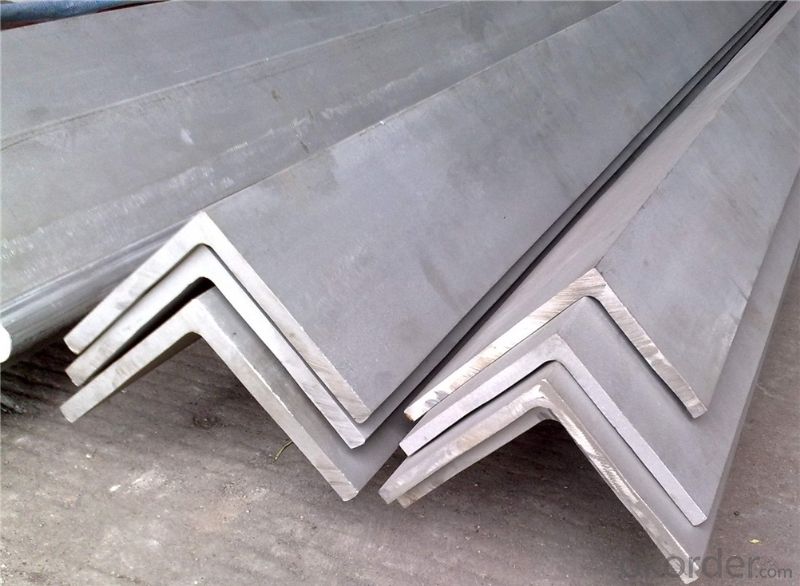

A110*110*9 Equal steel Angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of JIS SS400 Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Invoicing on theoretical weight or actual weight as customer request

3.Material: JIS G3192,SS400;SS540.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material Specifications:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS330 | ≧205 | ≧195 | ≧175 | ≧165 | 330-430 |

SS400 | ≧245 | ≧235 | ≧215 | ≧205 | 400-510 |

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

SS540 | ≧400 | ≧390 | - | - | ≧540 |

Usage & Applications Angle Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel angles be used for door frames?

- Yes, steel angles can be used for door frames. Steel angles provide strength and stability, making them a suitable choice for supporting and reinforcing door frames.

- Q: How do you cut steel angles to size?

- To achieve the desired size for steel angles, one can employ various techniques depending on the available tools. Here are a few commonly used methods: 1. Angle Grinder Method: A versatile tool, the angle grinder, can be utilized for cutting steel angles. Make sure to attach a cutting disc suitable for metal cutting to the grinder. Mark the desired length on the angle and securely clamp it down. Carefully follow the marked line using the grinder, applying even pressure to cut through the steel. Remember to take necessary safety precautions, such as wearing protective eyewear and gloves, and remain cautious of any sparks produced during the cutting process. 2. Bandsaw Technique: If a bandsaw is accessible, it can be an efficient tool for cutting steel angles. Ensure that the bandsaw is equipped with a blade specifically designed for metal cutting. Securely clamp the angle, aligning the marked line with the path of the blade. Start the bandsaw and gradually feed the angle into the blade, maintaining a steady pace to achieve a clean cut. 3. Hacksaw Approach: Although a slower method, a hacksaw can also be employed for cutting steel angles. Begin by securely clamping the angle to a workbench or vise. Use a square to mark a straight cutting line on the angle, then carefully saw along the line. Apply steady pressure while sawing to maintain control and achieve a clean cut. Remember to use a blade suitable for cutting metal and take breaks if necessary to avoid fatigue. Regardless of the chosen method, it is crucial to prioritize safety precautions, such as wearing appropriate protective gear and ensuring a clear and well-ventilated work area. Furthermore, always double-check measurements and utilize proper techniques to achieve accurate cuts.

- Q: Can steel angles be used in the construction of staircases?

- Indeed, staircases can be constructed using steel angles. Due to their strength and versatility, steel angles are frequently employed as structural elements in construction. In the context of staircases, steel angles serve to offer support and stability to the entire structure. They can establish the framework for the stairs, providing support for the treads and risers. Moreover, steel angles can serve as handrails or guardrails, ensuring a firm and safe grip for users. All in all, steel angles are a favored option for staircase construction due to their durability, capacity to bear loads, and aesthetic attractiveness.

- Q: What are the common design codes or standards for steel angles?

- There are several common design codes and standards that govern the use of steel angles in structural design. These codes and standards ensure that the angles are designed and manufactured to meet certain safety and performance criteria. One of the most widely used design codes for steel angles is the American Institute of Steel Construction (AISC) Manual of Steel Construction. The AISC provides comprehensive guidelines and specifications for the design, fabrication, and erection of steel structures, including angles. This manual includes detailed information on the design strength, allowable stress levels, and geometric properties of angles. In addition to the AISC Manual, other design codes and standards may also be applicable depending on the specific project and location. These include international standards such as the Eurocode, British Standards (BS), and Australian Standards (AS). Each of these standards may have slightly different requirements for the design and use of steel angles, so it is important to consult the appropriate standard for the specific project. Furthermore, the American Society for Testing and Materials (ASTM) has established standards for the physical and mechanical properties of steel angles. These standards ensure that the angles meet certain quality and performance requirements. The most commonly used ASTM standard for steel angles is ASTM A36, which specifies the general requirements for carbon structural steel. Overall, the common design codes and standards for steel angles provide guidance on factors such as load capacity, strength, and safety considerations. Adhering to these codes and standards ensures that steel angles are designed and used in a manner that promotes structural integrity and reliability.

- Q: How do you calculate the second moment of area for a steel angle?

- To calculate the second moment of area for a steel angle, you need to follow a step-by-step process. Here's how you can do it: 1. Begin by drawing the cross-section of the steel angle on a piece of paper or using a CAD software. Make sure to label all the dimensions accurately. 2. Divide the angle into smaller geometric shapes, such as rectangles and triangles, which are easier to calculate the second moment of area for. 3. Calculate the individual second moments of area for each geometric shape. The formula for the second moment of area, also known as the moment of inertia, varies depending on the shape. For rectangles, the formula is (b * h^3) / 12, where b is the base and h is the height. For triangles, the formula is (b * h^3) / 36, where b is the base and h is the height. Adjust the formulas based on the orientation and position of the shapes within the angle. 4. Sum up the individual second moments of area for all the shapes within the angle. If there are any holes or cutouts in the angle, subtract their second moments of area from the total. 5. Once you have calculated the second moments of area for all the shapes and accounted for any cutouts, add them up to obtain the total second moment of area for the steel angle. It's important to note that the second moment of area represents the resistance of a cross-section to bending. It is a crucial parameter in structural analysis and design, as it helps determine the strength and stability of a member under loads.

- Q: Are steel angles suitable for architectural cladding?

- Architectural cladding can indeed utilize steel angles effectively. Due to their robustness, strength, and adaptability, steel angles find wide usage in architectural settings. They offer a sturdy framework capable of supporting a range of cladding materials, including metal panels, glass, and composites. Architects can customize steel angles to suit various sizes and shapes, enabling them to achieve desired aesthetics and design specifications. Moreover, steel angles allow for easy fabrication and installation, making them a cost-efficient option for architectural cladding. Nevertheless, when selecting steel angles for cladding applications, it is crucial to consider factors like corrosion resistance, weather resistance, and maintenance requirements.

- Q: How do steel angles perform in terms of impact resistance?

- Steel angles are known for their excellent impact resistance due to their structural properties and high tensile strength. They can effectively absorb and distribute the force from impacts, making them highly reliable in applications where impact resistance is crucial.

- Q: How do steel angles perform in terms of electromagnetic shielding?

- Steel angles perform well in terms of electromagnetic shielding due to their high electrical conductivity and magnetic permeability. The angular shape of the steel angles helps to redirect and dissipate electromagnetic waves, effectively reducing the amount of electromagnetic radiation that can pass through. This makes steel angles an excellent choice for applications requiring electromagnetic shielding, such as in electronic enclosures or electromagnetic interference (EMI) shielding.

- Q: Can steel angles be used for manufacturing furniture?

- Yes, steel angles can be used for manufacturing furniture. Steel angles are versatile and durable, making them suitable for various applications including furniture manufacturing. They can be used to create strong and sturdy frames, legs, and supports for different types of furniture such as tables, chairs, shelves, and cabinets. Steel angles are known for their strength and structural integrity, making them an excellent choice for furniture that needs to withstand heavy loads or have a long lifespan. Additionally, steel angles can be easily welded, cut, and shaped to fit specific design requirements, allowing for customization and creativity in furniture manufacturing.

- Q: What is the cost of steel angles?

- The cost of steel angles can vary depending on various factors such as the type of steel, the length and thickness of the angle, and the supplier. Generally, the price of steel angles is determined by the current market rates for steel, which can fluctuate over time. It is advisable to contact different suppliers or check online platforms to get specific price quotes for the steel angles you require.

Send your message to us

A110*110*9 Equal steel Angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords